Precision Manifold Brackets For Stable Plumbing Systems

2025-07-25

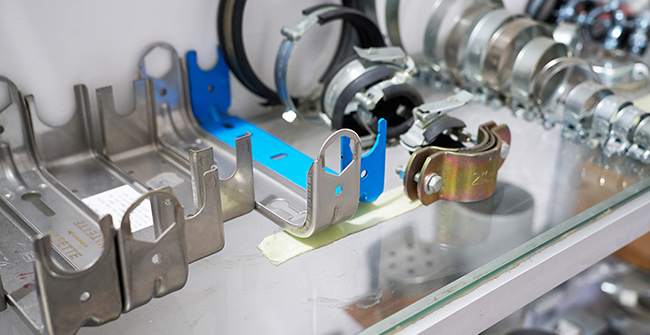

In the realm of plumbing systems, the importance of choosing durable and stable components cannot be overstated. Manifold brackets, along with water meter brackets, are essential elements that support and maintain the integrity of plumbing installations. These components play a crucial role in securing pipes and ensuring the proper flow of water in both residential and commercial environments. By selecting the right materials and designs, manifold brackets contribute to a plumbing system's efficiency and long-term performance.

Functionality of Manifold Brackets in Plumbing Systems

Manifold brackets are primarily used to hold and support plumbing manifolds, which distribute water to various parts of a system. They secure the manifold in place, preventing movement or vibrations that could cause damage to the pipes or leaks. These brackets must be strong enough to handle the weight and pressure of the manifold, but also designed to fit the specific needs of each plumbing system. The correct choice of materials and proper installation ensures that the plumbing system operates smoothly and consistently.

Material Considerations for Stability and Durability

Choosing the right material for manifold brackets is crucial for ensuring the system’s stability and longevity. Several materials are commonly used for these brackets, each offering distinct advantages depending on the application.

Steel, for instance, is a widely used material due to its strength and durability. It is often chosen for larger, more complex systems where high pressure and heavy loads are involved. Steel’s resistance to wear and corrosion makes it a popular choice for industrial applications.

Brass is another common material, known for its corrosion resistance and excellent strength. It is ideal for plumbing systems where aesthetic appeal and resistance to environmental factors are priorities. Brass manifolds are particularly useful in systems exposed to moisture and fluctuating temperatures.

For smaller residential systems, aluminum can be a practical choice. It is lightweight and easy to install, providing an affordable option for homeowners. Although not as strong as steel or brass, aluminum is sufficient for low-load applications and is resistant to corrosion, especially when treated.

Water Meter Brackets: Ensuring Accuracy and Durability

Water meter brackets play a vital role in securing water meters, which measure water consumption in a building or facility. These brackets ensure that the meter is fixed in place, preventing any movement that could lead to inaccurate readings or potential damage. Like manifold brackets, water meter brackets must be designed to withstand the environmental conditions they are exposed to, including moisture, temperature variations, and mechanical stress.

Water meter brackets are often made from materials that offer both strength and resistance to corrosion, such as stainless steel or brass. Their design must allow for easy installation and maintenance, ensuring that the meter can be read and serviced without difficulty. Depending on the system's requirements, the material and size of the water meter bracket may vary to provide the necessary support and protection.

Customization for Specific Piping Needs

In some cases, a piping system requires specialized manifold or water meter brackets. Customization enables manufacturers to design brackets that fit a specific system configuration, providing additional flexibility for complex installations. Custom brackets can meet specific size requirements, load capacities, or material preferences to help the piping system achieve optimal performance.

Manufacturers that offer custom solutions typically work closely with their customers to understand the specific needs of the system and provide custom brackets that meet technical and aesthetic requirements. This precision helps avoid issues such as improper installation, unnecessary stress on the pipes, and inefficient water delivery.

Quality Control and Long-Term Performance

To ensure the stability and durability of manifold and water meter brackets, strict quality control is required during production. From material selection to final inspection, strict standards are followed at each stage of manufacturing to ensure that each bracket meets the necessary performance and safety requirements. The use of advanced manufacturing techniques and continuous quality monitoring helps ensure that each component performs well over the long term, even under harsh conditions.

In addition, regular maintenance and inspections are essential to detect potential problems before they affect system performance. Keeping a close eye on wear and ensuring brackets are securely fastened can avoid costly repairs or replacements in the future.

Piping systems can achieve greater stability, efficiency and longevity by selecting accurate and properly designed manifolds and water meter brackets. Whether for residential or commercial use, these components provide the necessary support for smooth operation and reliable performance.

русский

русский  Español

Español