-

Precision Manifold Brackets For Stable Plumbing Systems

Jul 25, 2025

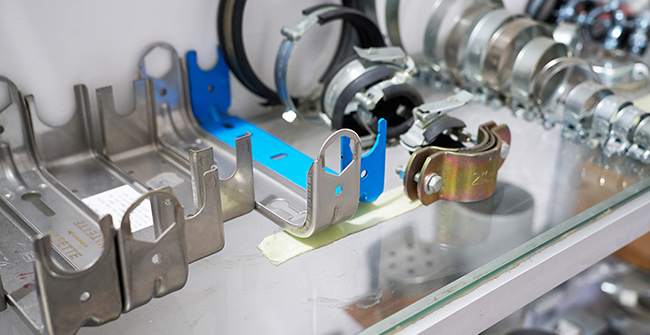

In the realm of plumbing systems, the importance of choosing durable and stable components cannot be overstated. Manifold brackets, along with water meter brackets, are essential elements that support and maintain the integrity of plumbing installations. These components play a crucial role in securing pipes and ensuring the proper flow of water in both residential and commercial environments. By selecting the right materials and designs, manifold brackets contribute to a plumbing system's efficiency and long-term performance.

Functionality of Manifold Brackets in Plumbing Systems

Manifold brackets are primarily used to hold and support plumbing manifolds, which distribute water to various parts of a system. They secure the manifold in place, preventing movement or vibrations that could cause damage to the pipes or leaks. These brackets must be strong enough to handle the weight and pressure of the manifold, but also designed to fit the specific needs of each plumbing system. The correct choice of materials and proper installation ensures that the plumbing system operates smoothly and consistently.

Material Considerations for Stability and Durability

Choosing the right material for manifold brackets is crucial for ensuring the system’s stability and longevity. Several materials are commonly used for these brackets, each offering distinct advantages depending on the application.

Steel, for instance, is a widely used material due to its strength and durability. It is often chosen for larger, more complex systems where high pressure and heavy loads are involved. Steel’s resistance to wear and corrosion makes it a popular choice for industrial applications.

Brass is another common material, known for its corrosion resistance and excellent strength. It is ideal for plumbing systems where aesthetic appeal and resistance to environmental factors are priorities. Brass manifolds are particularly useful in systems exposed to moisture and fluctuating temperatures.

For smaller residential systems, aluminum can be a practical choice. It is lightweight and easy to install, providing an affordable option for homeowners. Although not as strong as steel or brass, aluminum is sufficient for low-load applications and is resistant to corrosion, especially when treated.

Water Meter Brackets: Ensuring Accuracy and Durability

Water meter brackets play a vital role in securing water meters, which measure water consumption in a building or facility. These brackets ensure that the meter is fixed in place, preventing any movement that could lead to inaccurate readings or potential damage. Like manifold brackets, water meter brackets must be designed to withstand the environmental conditions they are exposed to, including moisture, temperature variations, and mechanical stress.

Water meter brackets are often made from materials that offer both strength and resistance to corrosion, such as stainless steel or brass. Their design must allow for easy installation and maintenance, ensuring that the meter can be read and serviced without difficulty. Depending on the system's requirements, the material and size of the water meter bracket may vary to provide the necessary support and protection.

Customization for Specific Piping Needs

In some cases, a piping system requires specialized manifold or water meter brackets. Customization enables manufacturers to design brackets that fit a specific system configuration, providing additional flexibility for complex installations. Custom brackets can meet specific size requirements, load capacities, or material preferences to help the piping system achieve optimal performance.

Manufacturers that offer custom solutions typically work closely with their customers to understand the specific needs of the system and provide custom brackets that meet technical and aesthetic requirements. This precision helps avoid issues such as improper installation, unnecessary stress on the pipes, and inefficient water delivery.

Quality Control and Long-Term Performance

To ensure the stability and durability of manifold and water meter brackets, strict quality control is required during production. From material selection to final inspection, strict standards are followed at each stage of manufacturing to ensure that each bracket meets the necessary performance and safety requirements. The use of advanced manufacturing techniques and continuous quality monitoring helps ensure that each component performs well over the long term, even under harsh conditions.

In addition, regular maintenance and inspections are essential to detect potential problems before they affect system performance. Keeping a close eye on wear and ensuring brackets are securely fastened can avoid costly repairs or replacements in the future.

Piping systems can achieve greater stability, efficiency and longevity by selecting accurate and properly designed manifolds and water meter brackets. Whether for residential or commercial use, these components provide the necessary support for smooth operation and reliable performance.

-

Selecting Materials For Manifold Brackets

Jul 18, 2025

Choosing the right material for manifold brackets is very important. It makes sure the system is stable, safe, and lasts a long time. The material you choose changes how durable it is, how easy it is to install, how much maintenance it needs, and how well the whole system works. You might be working on a home system or a factory system. You might be adding parts like a water meter bracket. Knowing your material options is important. It helps you make a good choice.

Key Things to Think About When Choosing Material

When you pick materials for manifold brackets, think about a few things. Think about strength, fight against rust, and how it works with other parts. The material must handle the stress on it. This includes contact with water, high pressure, and things like temperature changes and moisture. Outside conditions matter too. Things like rain or humidity will change your material choice. What the system will be used for also matters.

Common Materials for Manifold Brackets

Stainless steel is used often for manifold brackets. It is strong, fights corrosion well, and is durable. It is perfect for systems that get wet or face bad weather. Stainless steel works inside and outside. It can handle high heat and high pressure. This makes it good for tough places.

Brass is another material chosen often for manifold brackets. This is especially true in plumbing systems. It fights corrosion naturally. This makes it ideal for water systems. It is softer than stainless steel. But brass has enough strength for many uses. It works very well in places that rust easily. These places include coastal areas or factories.

Aluminum is a light material. It is used often for lighter jobs. It fights corrosion well, especially if it is anodized. It is not as strong as stainless steel or brass. But aluminum costs less. It is good for smaller home setups. In these setups, the brackets do not hold heavy weight. It is also easy to handle when you install it.

Carbon steel is another choice. It is known for strength. But it rusts more easily than stainless steel and brass. Carbon steel is good for inside places. This is especially true if it has a protective coating like galvanization. It is a low-cost choice. It is for jobs where strength is more important than fighting rust.

Environmental Factors and Uses

The place where the manifold system will go is important for material choice. For systems in rain, moisture, or extreme conditions, stainless steel or brass are better. They fight corrosion well. If the system is inside or in a controlled place, aluminum or carbon steel might work. They are lighter and cost less.

You also need to make sure the material works with other system parts. For example, brass is often used with other brass parts. This stops a certain kind of corrosion. Stainless steel needs to be matched with materials that will not cause bad reactions.

Maintenance and Lifespan

How long a manifold bracket lasts depends on the material's fight against wear. Stainless steel and brass need very little care. They only need cleaning now and then. Aluminum and carbon steel might need more regular checks and new coatings to stop rust. Taking good care will make the bracket last longer and work reliably.

When you pick a material for a manifold bracket, think about its use, what it will be exposed to, and its traits like strength and rust resistance. Stainless steel, brass, aluminum, and carbon steel all have good points. Choosing the right materials can make sure your manifold system stays strong, works right, and is cost-effective for many years.

-

Water Meter Bracket Compatibility Tips

Jul 11, 2025

When choosing the right water meter bracket, ensuring compatibility with the water meter and the surrounding installation setup is crucial for optimal performance. Water meter brackets not only support the weight and structure of the meter but also ensure proper alignment and easy access for maintenance. Proper installation can extend the lifespan of both the bracket and the water meter, making the right selection an essential part of a reliable system.

Understanding Water Meter Bracket Compatibility

Water meter brackets are designed to securely hold water meters in place, making them a vital component of water measurement systems in both residential and industrial settings. Compatibility between the water meter and the bracket is important to ensure stability, prevent damage, and make installation straightforward.

The first step in selecting a compatible water meter bracket is to consider the dimensions of the water meter itself. The bracket must fit snugly around the meter without creating undue pressure on the unit. This means checking the diameter, length, and weight of the meter, which will influence the size and design of the bracket. A bracket that is too small may not securely hold the meter, while one that is too large can cause unnecessary movement, potentially leading to inaccuracies or damage.

In addition to size, material compatibility is another crucial consideration. Water meters are commonly made from materials like brass, stainless steel, or plastic. The bracket material should be chosen to complement the water meter's material to prevent corrosion, especially in environments where water is used regularly, such as in outdoor installations or in areas with high humidity. Stainless steel and other corrosion-resistant materials are often preferred for long-lasting performance.

Design Features to Look For

Besides ensuring that the bracket fits the meter, design features also play a significant role in the bracket's overall functionality. Adjustable brackets, for example, can be a good option if there is variability in water meter size or if you expect future upgrades or replacements. These brackets can accommodate different meter sizes and are especially useful in large-scale installations where precision and flexibility are important.

For added convenience, some water meter brackets come with built-in features like lock mechanisms or mounting holes for easy installation and secure attachment to the wall or floor. These features improve the overall stability of the water meter and simplify the installation process, reducing the chances of errors or the need for adjustments.

Installation and Maintenance Considerations

When installing a water meter bracket, it's essential to follow manufacturer guidelines to ensure proper placement. Installing the bracket at an appropriate height and angle will make it easier to read the meter and facilitate quick access for maintenance and repairs. It's important to make sure that the bracket supports the meter without obstructing any connections or valves. The bracket should also allow for easy removal and replacement of the meter if necessary, without causing damage to the surrounding pipes or fittings.

Maintenance of the water meter bracket is equally important. Regular checks for signs of wear and tear, particularly in high-use environments, will ensure that the bracket continues to hold the meter securely over time. Lubricating the moving parts of adjustable brackets or checking for any rust or corrosion on metal parts will also help to extend the life of the bracket.

Choosing the Right Manifold Bracket for Water Meter Installations

When considering the use of water meter brackets in conjunction with manifold brackets, compatibility between the two becomes even more critical. Manifold brackets often house multiple meters in a single system, which requires precise alignment to ensure accurate readings for each individual meter. The placement of the manifold bracket and water meter bracket should allow for proper flow regulation and ease of monitoring. Make sure the manifold bracket is sturdy enough to hold multiple meters without compromising the accuracy or stability of the system.

Selecting the right water meter bracket involves more than just choosing a product that fits the meter. Ensuring compatibility in terms of size, material, and design features will ensure long-term functionality and ease of use. By taking the time to choose a high-quality bracket that suits the specific needs of your installation, you can prevent unnecessary repairs and ensure reliable water measurement for years to come. Proper maintenance and thoughtful installation will further enhance the durability and performance of your system.

-

Manifold Bracket Sizing Made Simple

Jul 04, 2025

Yuhuan Jinyi Metal Products Co., Ltd. makes hardware products like manifold brackets and water meter brackets. These parts help hold pipes and meters firmly in place. Picking the right size for these brackets is important. It helps keep installations stable and safe for a long time.

What You Need to Know About Manifold Bracket Size

First, you should know the size of the manifold. This means its length, width, and height. Also, look at how many connections or ports it has. Different manifolds need different bracket sizes. The bracket should hold the manifold firmly. But it also needs enough space so workers can install it or fix it later. If the bracket is too small, the manifold might not fit properly or could move. If it is too big, the bracket might not support the manifold well.

Materials matter too. Manifold brackets are usually made from steel, stainless steel, or brass. Each material has different strength and corrosion resistance. When choosing the bracket size, you need to consider these differences. The right size helps make sure the bracket holds the manifold’s weight safely and lasts a long time, even in harsh environments.

Water Meter Bracket Size Matters Too

Water meters come in many sizes and shapes. They are often installed in tight spaces on pipes. So the bracket size must fit well with the meter’s physical size. It must also match the pipe layout. The bracket should be easy to reach so workers can read the meter or do maintenance. If the bracket is too tight, it makes repairs harder. If it is too loose, the meter might move and cause leaks or damage.

Custom brackets are common because every installation is different. By measuring the meter and the installation space carefully, manufacturers can make brackets that fit well.A good fit helps make sure the meter stays stable and works well over time.

How We Control Quality and Customization

At Yuhuan Jinyi Metal Products, we offer custom design services for manifold and water meter brackets. We carefully select raw materials from trusted suppliers. Then, we use advanced manufacturing processes and strict quality controls. This helps us keep the size and shape of each bracket accurate. We also make sure the bracket’s strength meets the needs of different projects.

We keep detailed records of every production batch. This lets us trace products if customers have questions or issues later. Our quality control reduces problems caused by incorrect bracket sizes or weak materials. This makes projects run more smoothly and saves time and cost for customers.

Tips for Adjusting Bracket Size On Site

When installing brackets, it’s important to consider the actual site conditions. Walls, pipes, and the environment may affect bracket size and installation methods. For example, rough walls might need bigger brackets or special mounts. Pipes may have bends or fittings that require custom bracket shapes.

Before finalizing bracket sizes, it's helpful to communicate closely with the manufacturer. Share detailed measurements and photos of the site if possible. This helps avoid mistakes that could delay the project or require rework.

Also, always leave some space around the bracket. Too tight installations make maintenance difficult. Too loose installations risk instability and material waste. Experienced manufacturers can offer practical advice based on years of industry knowledge. They can suggest size adjustments that balance ease of installation, durability, and cost.

Knowing how to size manifold and water meter brackets well can simplify installation and improve product life. Yuhuan Jinyi Metal Products is ready to support your projects with customized, high-quality brackets that fit your exact needs. We aim to make your work easier and more efficient through practical solutions and solid quality control.

-

Pipe Straps: The Unsung Heroes of Pipe Installation and Structural Support

Jun 27, 2025

In the vast world of construction, plumbing, and industrial assembly, small components often play pivotal roles in ensuring safety, efficiency, and durability. One such essential yet often overlooked component is the pipe strap. These simple devices are foundational in securing piping systems, contributing to the stability and long-term performance of plumbing, HVAC, and electrical conduit installations across residential, commercial, and industrial projects.

While clamps and brackets may dominate headlines in fastening technology, pipe straps hold their own with unique benefits and specific use cases that make them indispensable.

Understanding the Pipe Strap’s Role

Pipe straps are designed to anchor piping systems to walls, ceilings, or floors. They are typically U-shaped or semi-circular in design and wrap around the pipe, fastening it securely to a flat surface. These straps come in various materials such as galvanized steel, stainless steel, copper, and plastic to match the requirements of the installation environment.Unlike general-purpose clamps, pipe straps are specifically crafted to fit the diameter of piping, offering a snug and secure hold that resists movement, sagging, or vibrations over time. This level of fit is critical in maintaining the structural integrity of a pipe system and ensuring it remains leak-free and noise-free under stress.

Variety and Material Options for Every Application

One of the major strengths of pipe straps is the range of materials and designs available to meet industry-specific demands. For example:Galvanized Steel Pipe Straps are commonly used in construction and plumbing projects due to their rust resistance and affordability.

Stainless Steel Pipe Straps offer corrosion resistance and are ideal for marine environments or chemical facilities.

Plastic Pipe Straps are lightweight, non-conductive, and suitable for indoor applications like electrical conduit or PEX tubing installations.

Copper Pipe Straps are often chosen in plumbing where copper piping is used, maintaining aesthetic consistency and compatibility with the piping material.

Additionally, there are single-hole and two-hole varieties, providing different levels of support depending on the length of pipe and mounting surface. The selection flexibility ensures that pipe straps are suitable for securing everything from small water lines to large HVAC ductwork.

Supporting a Range of Industries

Pipe straps are used across numerous sectors, each with unique challenges and safety requirements. In residential plumbing, they prevent pipes from rattling within wall cavities and ensure proper slope for drainage. In commercial HVAC systems, they secure ducting or refrigerant lines to walls and ceilings, vibration and wear.In industrial plants, where high-pressure lines carry steam, gases, or chemicals, pipe straps contribute to the overall containment system’s safety, often working alongside seismic bracing and insulation components. Even in the electrical field, conduit straps are used to hold metal or PVC electrical conduits in place, protecting wires from movement and potential damage.

Advantages of Using Pipe Straps

While simple in design, pipe straps offer several advantages that elevate their utility in construction and maintenance:Cost-Effectiveness: Pipe straps are low-cost components that deliver significant structural benefits, making them budget-friendly for large-scale projects.

Ease of Installation: With just a few screws or nails, a pipe strap can be quickly fastened, saving labor time and allowing faster project completion.

Space Efficiency: They hold pipes snugly against walls or ceilings, optimizing space usage, especially in tight or concealed installations.

Vibration Dampening: When properly installed, pipe straps minimize unwanted movement or vibrations, extending the life of the piping system.

Compliance: Using the correct type of pipe strap ensures code compliance in plumbing and electrical installations, which is crucial for safety inspections and building certifications.

Emerging Innovations and Standards

As construction methods evolve and building codes tighten, pipe strap manufacturers are responding with new innovations. Some modern straps feature insulated linings to reduce thermal bridging and prevent condensation. Others are pre-coated for added corrosion resistance in harsh environments.There is also increasing focus on seismic-rated pipe straps, particularly in earthquake-prone regions. These products meet specific standards for anchoring and bracing, ensuring that pipe systems remain intact during seismic activity.

Furthermore, sustainability is becoming a priority, with some manufacturers now offering eco-friendly or recycled material versions of common pipe straps, helping contractors reduce environmental impact while maintaining performance.

-

Shower Tray Support Frames: Boosting Installation Efficiency and Structural Integrity in Modern Bathrooms

Jun 20, 2025

As bathroom renovation and construction trends continue to prioritize sleek aesthetics and durable functionality, shower tray support frames have become indispensable tools in the plumbing and interior design industries. These support systems are how shower trays are installed, offering enhanced stability, quicker installations, and long-term reliability without compromising the bathroom’s visual harmony.

Shower tray support frames are engineered to provide a robust substructure beneath shower bases, distributing weight evenly and preventing flexing or movement over time. As modern bathrooms increasingly incorporate larger and more sophisticated shower units, the demand for dependable tray support solutions has grown substantially.

One of the benefits of using a shower tray support frame is its ability to streamline the installation process. Traditional methods often require manual leveling with mortar or foam, which can be time-consuming and error-prone. In contrast, pre-engineered support frames are typically adjustable and pre-leveled, allowing installers to quickly position and secure the tray without the guesswork.

For contractors working on multiple installations or projects with tight timelines, these frames offer significant labor savings. Similarly, DIY homeowners benefit from simplified instructions and reduced risk of improper installation, to fewer callbacks or repairs in the future.

Some newer models even feature integrated leveling feet or telescoping arms, enabling fine adjustments without additional tools. This ensures that the shower tray sits perfectly flat, preventing issues like water pooling or uneven drainage—common problems associated with misaligned bases.

Reinforcing Long-Term Structural Integrity

While aesthetics often steal the spotlight in bathroom design, structural integrity is the cornerstone of a successful installation. Shower trays are subjected to daily stress from water weight and human use. Without proper support underneath, trays—especially those made of lightweight materials like acrylic—can crack, flex, or shift over time.

A well-constructed support frame eliminates these risks by offering a stable, evenly distributed foundation. This is particularly valuable for stone or composite trays, which are heavier and require robust underpinnings to maintain their position and durability. By ensuring that the entire weight of the tray is supported evenly across the floor surface, support frames significantly extend the life span of the installation.

Wide Compatibility Across Shower Tray Materials

One of the challenges in modern bathroom design is the variety of shower tray materials used, ranging from lightweight plastic and fiberglass to luxurious stone resin and porcelain. A quality support frame addresses this challenge by offering universal compatibility with a range of base materials.

This versatility allows designers and installers to choose the ideal shower tray for the project’s style and functionality without worrying about whether a suitable support system is available. Manufacturers have responded to this demand by developing modular frames and kits that can accommodate different materials and sizes, making it easier to standardize the installation process across multiple projects.

Aesthetic Discretion in Contemporary Designs

While the primary role of a shower tray support frame is structural, modern units also consider the visual aspect of installation. Many frames are designed to be completely hidden once the tray and tiling are in place, maintaining the clean, uninterrupted lines that characterize today’s bathrooms.

Hidden installation helps homeowners and designers achieve minimalist aesthetics without compromising safety or performance. For elevated or walk-in shower setups, this discretion is especially important. Homeowners enjoy the peace of mind of knowing a robust support system is in place—without having to see it.

Adapting to Modern Bathroom Trends

With the rising popularity of wet rooms and large-format shower areas, the adaptability of support frames is more important than ever. These frames can be customized to fit irregularly shaped trays or oversized bases, making them ideal for bespoke bathroom designs.

Furthermore, as more homeowners embrace accessibility features like low-threshold entries and wheelchair-friendly showers, the need for secure, flush-mounted trays has increased. Support frames help achieve this by allowing precise control over tray height and placement.

-

Pipe Clamps: Essential Tools Delivering Portability and Efficient Workspace Management

Jun 13, 2025

Pipe clamps are a basic tool in workshops and on construction sites. People value them because they can hold materials very tightly. This is needed for building, putting things together, and fixing tasks. Besides their main job of holding tight, today's pipe clamps are also made to be easy to carry and store. These are important points that help people work faster and keep their work area neat.

Why Pipe Clamps Are Useful and Easy to Move

A key feature of pipe clamps is their light weight and small size. This lets users move them easily between different job places. They do not need to carry heavy loads or big boxes. You might work on a big building site, fix a plumbing problem, or build a wooden project in your home shop. Pipe clamps are very handy because of their easy size and weight.

Being easy to carry does more than just make the user less tired. It also lets you set up the clamps fast, right where you need them. This is very useful for workers and skilled people who go to different job sites often. Putting pipe clamps in a toolbox or a small bag is very simple. This helps workers keep a smooth workflow with less waiting.

Saving Space for a Cleaner Work Area

Pipe clamps are also very good for saving space. Their small size means they do not take up much room when you put them away. This helps keep the area clean and organized. This is very important in small workshops or crowded work trucks where storage space is limited.

You can pile pipe clamps neatly. You can also hang them on special racks, tool boards, or hooks. This uses the space on walls. Some makers also design clamps with parts you can take off or fold. This makes them take up even less space. Keeping pipe clamps organized stops them from getting damaged. It also makes them last longer and easy to find when you need them.

A clean work area is safer because there are fewer things to trip over. It also helps you work faster because you do not waste time looking for tools. Workers can pay more attention to their job when they know their tools are in order.

Uses in Different Jobs

People use pipe clamps in many different fields. This includes woodworking, metal work, plumbing, car repair, and construction. Their easy carry and storage benefits are very helpful in jobs where the work site changes often or where there is not much space.

- Woodworking: Pipe clamps are necessary for gluing, assembling, and holding wood pieces still. You can adjust them to fit different lengths of pipe. This gives you flexibility for projects of many sizes.

- Plumbing and HVAC: Light clamps make it fast to secure and line up pipes. This is true even in tight or awkward spaces. It speeds up installation and repair work.

- Metal Work: Portable pipe clamps hold metal parts steady for welding, cutting, or fitting. This makes the work more exact and safer.

- Construction: Putting together frames, scaffolding, or building parts on-site is easier with clamps you can move and store easily as the job moves forward.

Better Materials and Designs

New changes in materials and design have made pipe clamps even better to carry and use. Light metals, strong plastics, and handles shaped for the hand make them easy to hold. They are still strong.

Design features like quick-release parts and jaws you can adjust make setting up and removing clamps faster. This cuts down on work time and effort. Also, some clamps come with soft pads or coatings. These protect delicate materials from getting marked when clamped.

Makers are also making sure clamps are strong and resist rust. This is especially important for using them outside or in damp places. These improvements make sure portable clamps stay dependable for a long time, in all kinds of working conditions.

Saving Money and Staying Safe

Buying portable, easy-to-store pipe clamps has clear money benefits. Less physical tiredness means a lower chance of getting hurt at work. Managing tools well cuts down on waiting time and helps finish projects faster. This directly affects how much money a business makes.

Also, clamps that are taken care of and stored right tend to last longer. This means you do not have to buy new ones as often. Workers who can find good clamps quickly are more ready to do quality work. This makes customers happier and improves the name of the business.

The Right Way to Use and Take Care of Them

To get all these benefits, you must use and care for pipe clamps the right way. Always check a clamp before you use it. Look for cracks, worn parts, or bad threads. Make sure the clamp is tight enough for the job, but do not tighten it too much. Too much force can damage the clamp or the material you are holding.

After you use them, clean your pipe clamps. Wipe off any dirt, glue, or moisture. For metal clamps, a light coat of oil now and then can stop rust. Then, store them in a dry place.y do not get bent.

-

Radiator Mounting Brackets: Enhancing Installation Flexibility and Bathroom Design

Jun 06, 2025

Radiator mounting brackets are important metal parts. They are used to fix radiators to walls. Radiators are a common part of home heating systems. These brackets make sure the radiator is safe and does not fall. They also help the radiator look good in the room.

Why These Brackets Are Needed

Every radiator is heavy. It is even heavier when it is full of water. So, it needs strong support. Mounting brackets give this support. Without good brackets, a radiator could come loose. This could damage the wall or the pipes. It could also be dangerous for people. So, picking the right bracket is very important for safety and for the heating to work well.

One Type Fits Many Radiators

A good thing about modern brackets is that one type can fit many radiators. This is called a universal fit. These brackets are made to hold different sizes and shapes. You can use the same bracket for a small, flat radiator in a bathroom or a tall, column radiator in a hallway.

This is very helpful for everyone. For the seller, it is easier because they do not need to keep many different brackets. For the person installing it, it is easier because they are more likely to have the right bracket. It is also good if you are changing your old radiator for a new one. You might not need to change the brackets if you use this universal type. This saves time and money.

Brackets That You Can Adjust

Another helpful feature is adjustability. Some brackets let you move the radiator a little after it is on the wall. You can move it up or down. You can also move it left or right. This is very useful.

Why is this useful? It helps line up the radiator perfectly with the pipes coming from the wall. If the pipes are not exactly straight, you can adjust the radiator to match. This makes the connection better and avoids leaks. walls are not always perfectly flat. An adjustable bracket can help make the radiator sit flat against an uneven wall.It lets you make sure the radiator is perfectly level. A radiator that is not level does not look good and might not work as well.

This adjustability makes the installer's job easier. They can fix small problems on the spot. They do not need to make new holes in the wall or use extra parts.

Making the Bathroom Look Nice

Brackets are not just about function. They are also about how things look. People want their bathrooms to be beautiful. A rusty or ugly bracket can make the whole room look worse. So, manufacturers now think about design.

Many brackets now have a nice finish. They are painted with a strong powder coat in white or black. Others have a shiny chrome finish. This makes them look like other bathroom items, like towel rails or taps. Some brackets are even made to be hidden. You cannot see them after the radiator is on the wall. This gives a very clean and modern look.

When the brackets look good, they become part of the room's design. They do not draw bad attention. This means homeowners can have a warm bathroom that is also stylish.

Strong and Long-Lasting Materials

The material of the bracket is very important. Bathrooms are wet and humid places. This can make metal rust. A rusty bracket becomes weak and can break.

So, good brackets are made from materials that do not rust easily. They are often made from strong steel. The steel is treated with a special coating to protect it. Some are made from aluminum, which is lighter and also resists rust well. These strong materials mean the bracket will last for many years.

A durable bracket is a safe bracket. It will hold the radiator securely for a long time. It will not bend or sag. This protects your wall and your radiator. It also means you will not have to replace the brackets soon, which saves money in the long run.

New Ideas in the Market

The world of home improvement is always changing. People want things that are faster and easier to install. So, there are new brackets for radiators too.

Some new brackets have a snap-on design. This lets you put the radiator on the bracket quickly. Some brackets need no tools to adjust. These ideas help professional installers work faster. They also help people who like to do home projects themselves. It makes the job less difficult.

Also, more homes are using smart technology. Some new radiators have electronic thermostats or smart controls. New mounting brackets are made to work with these radiators. They have space for wires or special fittings. This shows that even a simple part like a bracket must change with new technology.

Thinking About the Environment

Today, many people think about the environment. They want products that are made in a good way. This is true for mounting brackets too.

Companies are trying to make brackets in a more eco-friendly way. They might use recycled steel. They might use production methods that create less pollution. Also, because the brackets are made to last longer, they create less waste. You do not need to throw them away and buy new ones often.

When you choose a good quality bracket, you are also helping the environment. You are buying something once, not many times.

How to Choose the Right Bracket

If you need to buy a radiator bracket, here are some tips. Know the weight and size of your radiator. The bracket must be made for a heavier weight than your radiator. This is for safety.Think about your wall. Is it a solid brick wall or a hollow drywall? For a hollow wall, you might need special plugs or a different bracket. Think about the look. Do you want a hidden bracket or a visible one in a nice finish?

Always read the instructions from the bracket maker. They will tell you the right way to install it. If you are not sure, ask a professional heating engineer. A good installation is very important.

Radiator mounting brackets are small but very important. They keep your radiator safe on the wall. Modern brackets are versatile, adjustable, and good-looking. They are made from strong materials to last. New designs make installation easier. When you choose a good bracket and install it well, you ensure your heating system works safely and looks great in your home for many years.

-

The Evolution and Innovation of Water Faucets in Modern Plumbing Systems

May 30, 2025

Water faucets are a key part of plumbing systems. They give controlled access to water in homes, businesses, and factories. Faucets have changed a lot over time. They started as simple manual devices. Now, they are advanced digital models.

The Important Role of Water Faucets in Plumbing Systems

Water faucets are very common in home and business plumbing. This makes water use easy for everyone. A good faucet must work well and last a long time. But today, needs have changed. People worry more about saving water. So, faucets are not just simple tools anymore. Now, they are part of a bigger plan for efficient water use and sustainable living.

Faucets are necessary for daily life. They give us hot and cold water for cleaning, cooking, drinking, and washing. Besides this basic job, faucets also add to the look of a kitchen or bathroom. Makers offer many styles, finishes, and shapes to suit different tastes. Also, faucet companies are thinking about the environment. They are adding features that save water. These features help use less water but still work well.

New Ideas in Water Faucet Technology

Over time, water faucet technology has improved a lot. These changes aim to make faucets more convenient, efficient, and eco-friendly. Several important innovations have made faucets key tools for modern water management.

Touchless and Sensor Faucets

A big innovation is the touchless or sensor faucet. These faucets use infrared sensors. The sensor sees a user's hands and turns the water on automatically. Touchless faucets have many benefits. They are more hygienic. They reduce water waste. And they are very convenient. You often see them in public restrooms, hospitals, and restaurant kitchens. Cleanliness and efficiency are very important there. Plus, these faucets save water. The water only runs when it is needed. This cuts down on useless water flow.

Water-Saving Faucets

People are more worried about water shortages and the environment now. So, makers have created water-saving faucets. These faucets use aerators and other tech. They reduce water flow but keep good water pressure. This helps people use less water without a bad experience. Low-flow faucets are now common in houses and offices. Governments and rules are pushing for better water efficiency. Putting water-saving features in faucets helps the planet. It also lowers the water bill for users.

Digital Faucets with Smart Controls

Another new development is the digital smart faucet. These faucets have digital screens. Users can set the exact water temperature and flow rate. They can even set a timer for the water. Smart faucets can connect to home automation systems. This means people can control the faucet from an app on their phone. They can also use voice commands with helpers like Amazon Alexa or Google Assistant. This is very convenient. But also, these smart faucets save energy and water. They give exact control, which reduces waste and cost.

Water Filtration Faucets

People are also more concerned about water quality. So, water filtration faucets are becoming popular. These faucets have built-in filters. The filters take out impurities and harmful things from the tap water. This makes the water taste better and be safer to drink. Some faucets use cartridges you can replace. Others have more advanced filter technology. They give clean water straight from the tap. These faucets are popular where people worry about water pollution. They are also good for families who want safe drinking water at home.

Looking Ahead: The Future of Faucets

The future of water faucets will likely bring even more change. One area is smarter technology. Faucets could learn a user's habits and adjust settings automatically. For example, a faucet might know your preferred morning shower temperature. Another idea is better water tracking. Faucets might have displays that show exactly how much water you use each time. This would help people understand and reduce their water use.

Also, materials used for faucets will improve. Scientists are looking at new, very strong coatings. These coatings would prevent the buildup of lime and dirt. This means faucets would stay cleaner and last longer with less cleaning. Also, we might see more use of recycled materials in making faucets. This would make them more environmentally friendly from the start.

Another possibility is faucets that work without any touch at all. Instead of a sensor, a simple voice command or a wave of the hand from a distance could control the water. This would be even more hygienic. It would also help people with limited movement who find handles difficult to use.

In cities with old pipes, water quality can change. Future faucets might have advanced sensors built into them. These sensors could check the water for safety in real time. A small light on the faucet could change color if the water is not safe to drink. This would give people immediate information about their water.

-

The Growing Demand for Shower Bases Support Frames in the Plumbing and Construction Industry

May 23, 2025

Shower bases are a crucial component in modern bathrooms, providing a solid foundation for shower enclosures and ensuring a stable, waterproof surface. However, the performance and longevity of a shower base are highly dependent on the support frame that holds it in place. The shower base support frame is an often-overlooked but essential element that ensures the durability, levelness, and overall functionality of the entire shower system. As the construction and renovation industries continue to focus on improving the quality and efficiency of plumbing installations, the demand for high-quality shower bases support frames is on the rise.

What is a Shower Bases Support Frame?

A shower base support frame is a structural component used to support and stabilize the shower tray or base. Typically constructed from strong materials such as galvanized steel, aluminum, or stainless steel, these frames are designed to bear the weight of the shower base and any users. They help to distribute the load evenly, prevent the shower base from warping, and ensure a solid, secure installation.Support frames are critical in areas where traditional shower trays, often made of acrylic or fiberglass, require additional reinforcement to handle the stresses of daily use. Without a robust support frame, the shower base could shift or sag over time, to cracks, leaks, and costly repairs. In addition to providing structural support, these frames also help maintain the proper drainage slope for water flow, ensuring the shower is functional and efficient.

Increased Focus on Durability and Longevity

One of the main factors driving the demand for high-quality shower bases support frames is the increasing emphasis on durability and longevity in modern construction projects. Homeowners and commercial property owners are looking for bathroom fixtures that are not only aesthetically pleasing but also reliable and long-lasting. The shower base support frame plays a critical role in ensuring that the shower base remains level and secure for many years, even with frequent use.

In response to this demand, manufacturers have started to develop support frames that are made from corrosion-resistant materials, such as stainless steel or coated metals, that can withstand the harsh environment of bathrooms, which are often exposed to moisture, heat, and chemicals. These advanced materials help to prevent rust and degradation, ensuring the structural integrity of the shower base over time.

Additionally, many manufacturers are investing in the design of adjustable and customizable support frames. These frames can be tailored to different shower sizes and configurations, offering greater flexibility for installation in a variety of bathroom layouts. Adjustable support frames also make the installation process easier, reducing labor costs and time spent on-site.

Enhancing Water Efficiency and Drainage

Water efficiency and proper drainage are key considerations in the design of modern plumbing systems. Shower bases support frames play a significant role in ensuring that water drains effectively from the shower area, preventing water from pooling or collecting in unwanted areas. Proper drainage is essential to avoid issues such as mold, mildew, and water damage, which can be costly to repair.By providing a stable and level surface for the shower base, the support frame ensures that the water flows toward the drain, reducing the risk of standing water. Some advanced support frames are even designed with built-in slope features, making it easier for contractors to install showers with the proper slope for drainage. This feature is especially beneficial for larger showers or walk-in shower systems, where water flow and drainage need to be precisely controlled.

As building codes and regulations become more stringent, the ability to design and install shower bases with efficient drainage systems has become more important. High-quality shower base support frames contribute to meeting these regulatory requirements while also providing long-term benefits to homeowners and businesses.

Sustainability in Shower Base Support Frames

Sustainability has become a major priority in the construction industry, and this trend is influencing the design of shower bases support frames. Many manufacturers are turning to environmentally friendly materials and manufacturing processes to reduce the environmental impact of their products. Materials like recycled aluminum, low-VOC coatings, and sustainable production methods are becoming more common in the development of shower base support frames. -

The Role of Water Meter Brackets in Modern Infrastructure Development

May 16, 2025

Water meter brackets are one of the integral components of modern infrastructure that often go unnoticed by the general public. These simple yet crucial devices hold and secure water meters, ensuring their accuracy, longevity, and ease of access. With the growing emphasis on smart cities, precision engineering, and sustainable water management, the demand for high-quality water meter brackets is on the rise. In this article, we’ll explore the importance of water meter brackets, the innovations surrounding their design, and how they are essential to improving water distribution and metering systems across the globe.

What Are Water Meter Brackets?

A water meter bracket is a mounting device designed to securely hold a water meter in place. These brackets are typically made of durable materials such as steel, stainless steel, or plastic, providing the strength and stability necessary to keep the water meter functioning properly in various environmental conditions. Water meters, which measure the amount of water consumed by a household or commercial facility, must be accurately installed to ensure the precision of the readings. Water meter brackets facilitate this by ensuring that the meter stays aligned and protected from damage over time.The design of water meter brackets can vary depending on the specific application, such as for residential, commercial, or industrial purposes. For example, brackets used in residential settings are generally simpler, offering easy installation and basic protection, while industrial-grade water meter brackets may have more complex designs for greater durability and resistance to harsh conditions.

The Importance of Water Meter Brackets in Water Management Systems

Water meter brackets play a crucial role in maintaining the integrity and reliability of water metering systems. They serve several important functions in water management systems:Accurate Readings and Measurement: For water meters to provide accurate readings, they must be securely installed in a stable position. Water meter brackets ensure that meters stay aligned and protected from shifting or damage that could cause inaccurate readings. Inaccurate readings can to incorrect billing, inefficiencies in water usage, and difficulty in managing water resources effectively. A properly installed meter, supported by a reliable bracket, helps utility companies maintain the accuracy of consumption data.

Protection from Environmental Factors: In areas where water meters are exposed to the elements, such as outdoors or in harsh climates, brackets provide added protection against temperature changes, moisture, and corrosion. This ensures that water meters remain functional and accurate, even in challenging conditions. For example, brackets made from corrosion-resistant materials like stainless steel or coated metals are particularly beneficial in regions with high humidity or salty air.

Ease of Access for Maintenance and Replacement: Brackets also make it easier for maintenance personnel to access and replace water meters when necessary. With the growing demand for smart water metering systems, which often require regular maintenance and updates, brackets that allow easy access to the meter are becoming increasingly valuable. In the event of meter failure or the need for upgrades, brackets allow for quick and efficient servicing.

Compliance with Regulations: In many countries, there are strict regulations regarding the installation and maintenance of water meters to ensure that they meet specific standards for accuracy and durability. Water meter brackets are often designed to comply with these regulations by supporting the meter in the required position and ensuring that it remains level and secure. Brackets that conform to industry standards help water utilities meet regulatory requirements and avoid costly penalties.

Innovations in Water Meter Bracket Design

As water management systems become more sophisticated, the design and manufacturing of water meter brackets are also evolving. The industry is seeing several key innovations in the development of these brackets, driven by advancements in technology and changing customer needs.Smart Meter Integration: With the rise of smart water meters, which allow for real-time data collection and remote monitoring, water meter brackets are being designed to accommodate these advanced devices. New brackets are being developed to support the integration of sensors and communication modules, which enable meters to transmit data to central systems for more efficient water management. These innovations ensure that water meter brackets remain relevant in the age of smart cities and the Internet of Things (IoT).

-

The Evolving Role of Bathroom Radiator Brackets in Modern Home Design

May 09, 2025

In the world of home improvement and interior design, the bathroom is often one of the overlooked spaces. However, as homeowners increasingly prioritize comfort and functionality, the importance of every detail has grown. Among the essential yet often underestimated components in a bathroom is the radiator bracket. These simple, yet crucial fixtures support and secure radiators in place, ensuring their stability and enhancing the overall aesthetic of the room.

Understanding the Function of Bathroom Radiator Brackets

Bathroom radiator brackets, while relatively small in size, play a significant role in the effective and safe installation of radiators. A radiator bracket is a device that supports a radiator, allowing it to be securely attached to the wall. This ensures that the radiator remains in position and functions properly. The bracket also ensures that the radiator is installed at an height, which is crucial for efficient heat distribution.Without high-quality radiator brackets, radiators may become unstable, which could lead to safety issues or decreased efficiency. They are typically designed to accommodate a wide range of radiator sizes, making them a versatile choice for different bathroom layouts.

Why Bathroom Radiator Brackets Are Essential

The use of bathroom radiator brackets has grown in popularity due to several key factors. These include the increasing demand for space-efficient bathroom designs, as well as a growing focus on energy efficiency and safety. Here’s why these brackets are indispensable:Maximizing Space: In smaller bathrooms, every inch of space counts. Radiators are often mounted on walls to save space on the floor, but this positioning requires secure and reliable support from radiator brackets. These brackets help keep the radiator safely attached to the wall, freeing up valuable floor space for other fixtures, such as sinks or storage solutions.

Enhancing Heat Distribution: A bathroom radiator must be positioned correctly to ensure even heat distribution. Radiator brackets are essential for achieving this, as they allow the radiator to be installed at the right height and angle for efficiency. Without the proper bracket, the radiator may be placed too low or high, leading to uneven heating and higher energy consumption.

Ensuring Safety: Radiators, especially large or heavy models, can pose a safety hazard if not securely fixed to the wall. Bathroom radiator brackets are designed to support the weight of the radiator, ensuring it remains stable over time. This is particularly important in high-moisture areas like bathrooms, where the risk of accidental falls or damage to the radiator is greater.

Supporting Modern Design Trends: Today’s bathroom designs often incorporate minimalist and sleek elements. Radiator brackets are available in a variety of styles, from traditional to contemporary, allowing homeowners to select brackets that complement their bathroom décor. These brackets can even become a design feature in their own right, with some brackets crafted from materials like stainless steel or chrome to match modern fixtures.

Materials and Styles of Bathroom Radiator Brackets

Radiator brackets come in various materials, including steel, brass, chrome, and aluminum. The choice of material not only impacts the bracket’s aesthetic but also its durability and resistance to corrosion. In bathrooms, where moisture is a constant concern, choosing the right material is essential for ensuring longevity and performance.Steel is a popular choice for bathroom radiator brackets due to its strength and durability. It provides robust support for radiators, ensuring they stay securely attached to the wall. Steel brackets are often coated to prevent rust and corrosion, which is important in a bathroom environment.

Chrome and brass brackets, on the other hand, are favored for their elegant appearance. These materials give a shiny, polished finish, contributing to a more luxurious and stylish bathroom. Chrome radiator brackets, in particular, are known for their resistance to corrosion, making them a practical option for humid spaces.

Aluminum brackets are another option, providing lightweight and corrosion-resistant support for radiators. Aluminum is a more budget-friendly material compared to stainless steel or brass, making it an attractive option for homeowners looking to save on installation costs.

русский

русский  Español

Español