Unseen Strength: Precision Support Frames Where Water Meets Weight

2025-08-08

In the infrastructure of wet spaces—from home bathrooms to commercial facilities—Shower Bases Support Frames and Decoupling Tank components work as unseen pillars of stability. These parts are often hidden. They solve the special problems of places where water, weight, and movement come together. They make sure structures stay safe and work properly for a long time. Their design focuses on practical answers to common problems. These problems include the pressure of daily use and the small movements of plumbing systems.

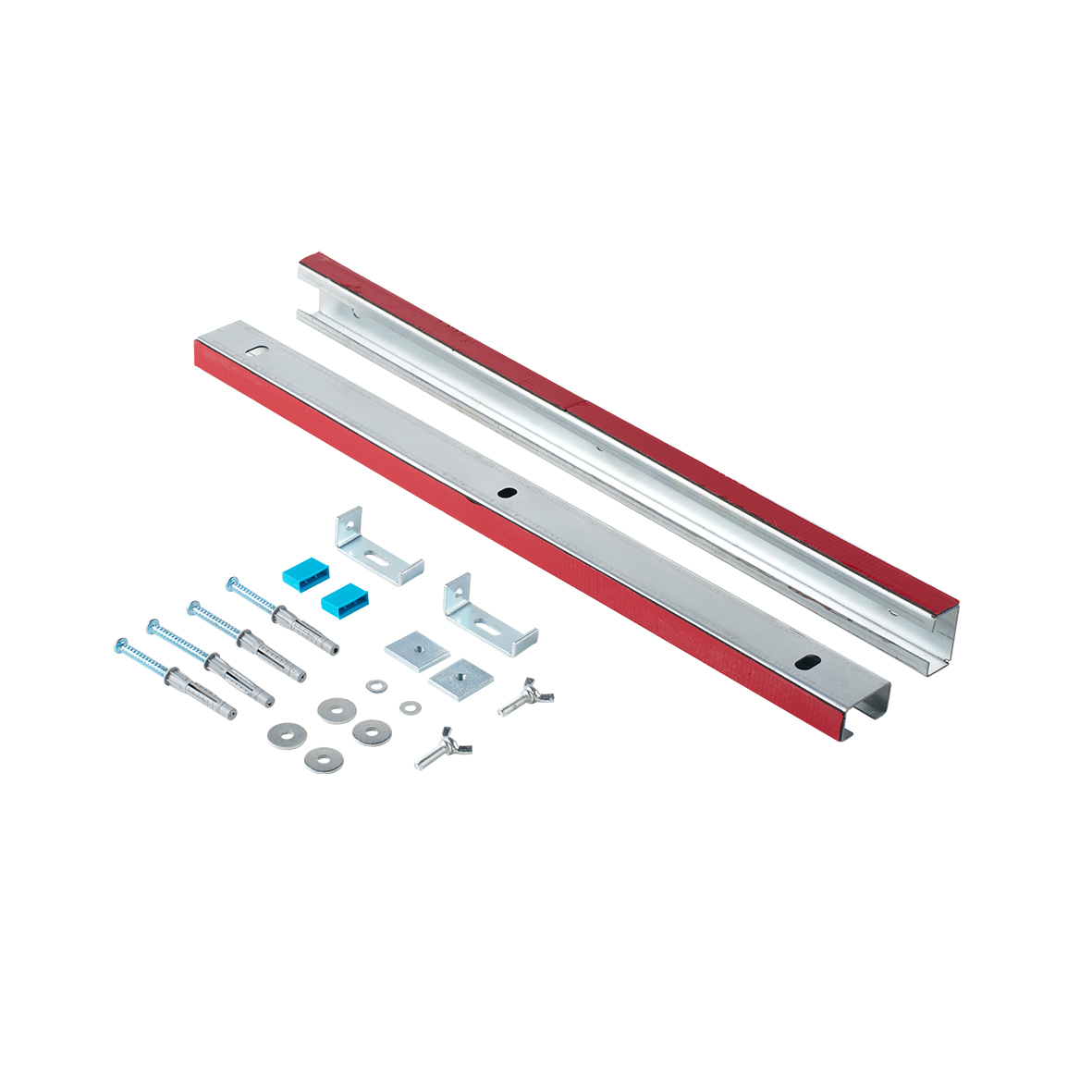

Shower Bases Support Frame: Bearing Weight, Resisting Moisture

The Shower Bases Support Frame is the foundational structure under shower pans. Its job is to spread weight evenly. This stops sagging, cracking, or movement. In homes, this means supporting the weight of the shower base itself, the water, and the people using it. This total weight is often hundreds of pounds. In commercial spaces, use is more frequent. So, the frame must also handle repeated stress without bending.

Materials are very important for their performance. Steel and stainless steel are common choices. They are chosen for their strength and their fight against corrosion. Steel frames are often galvanized. This makes a protective layer against moisture. This is a key need in places where water is always present. Stainless steel naturally resists rust. It is better in areas with high humidity or where cleaning chemicals might cause more wear.

Design details make them work better. Many frames have adjustable legs. This lets installers level the shower base even on uneven floors. This is a common issue in older buildings. Cross-bracing between frame parts adds stiffness. This stops side-to-side movement that could weaken the base over time. For bigger shower bases, frames may have extra support beams. These are placed to match the base’s strong points. This makes sure weight is spread across the whole floor, not just a few spots.

Decoupling Tank: Reducing Stress in Water Systems

Decoupling Tank parts solve different problems. They focus on lowering stress in plumbing systems. This stress is caused by movement, pressure changes, or heat expansion. These tanks work as go-betweens in water lines. They create a separation between rigid parts. This absorbs shifts that could cause leaks or pipe damage.

For example, in home plumbing, hot water makes pipes expand a little. Cold water makes them contract. Over time, this repeated movement can loosen connections or strain joints. A Decoupling Tank put near water heaters or where pipes turn creates a flexible point. It allows for expansion without passing stress to fixed parts like shower valves or wall pipes

Materials for these tanks are chosen for how long they last and how they work with water. Brass is often used. It is flexible and fights corrosion. Stainless steel parts give strength in high-pressure lines. The tank’s inside design has gaskets or diaphragms made from rubber or silicone. These bend with pressure changes to keep a tight seal without hard resistance. This flexibility makes sure the tank itself does not break.

How They Work Together in Wet Environments

In places like bathrooms, Shower Bases Support Frames and Decoupling Tank parts often work together. Each one handles a layer of structural strength. The support frame keeps the shower base stable under direct weight. At the same time, the decoupling tank protects the plumbing that feeds the shower from stress damage.

Think about a normal bathroom setup. The support frame holds the shower base to the floor. It stops movement that could break the seal between the base and the drain pipe. Also, a decoupling tank is put in the water line near the shower valve. It absorbs pressure spikes from the main water supply. This helps protect the valve and connecting pipes from stress every time the shower is turned on.

In commercial settings, like gym locker rooms or hotel bathrooms, this teamwork is even more important. High use means more frequent weight on shower bases and more frequent pressure changes in plumbing. A strong support frame stops early wear on shower pans. Also, well-placed decoupling tanks mean fewer pipe repairs are needed. This lowers maintenance costs over time.

Practical Things to Think About for Installation and Long Life

Putting these parts in needs care with specific details. This makes sure they work as planned. For Shower Bases Support Frames, correct sizing is key. Frames must fit the size of the shower base. Support points must line up with the base’s edges and drain. Installers should also check for level during setup. An uneven frame can make water pool in the shower. This raises the risk of leaks.

Maintenance steps are simple but important. Support frames should be checked now and then for signs of corrosion. This is especially true in areas with bad air flow. Tightening loose bolts or replacing rusty parts stops slow weakening. Decoupling tanks need checks of gaskets or diaphragms for wear. Worn seals can cause less flexibility or leaks. Replacing these parts when suggested makes sure the tank keeps absorbing stress well.

русский

русский  Español

Español