-

Everything You Need to Know about Manifold Bracket

Dec 05, 2025

In the world of automotive engineering, every component plays a crucial role in the overall performance of a vehicle. Among these, the manifold bracket often goes unnoticed, yet it serves as a vital link between the engine and its various systems. Designed to support and stabilize the manifold, this seemingly simple part is essential for maintaining efficiency and reliability. How does the choice of manifold bracket impact the performance of your vehicle?

What Exactly Is a Manifold Bracket?

At its simplest, a manifold bracket is a structural component that locates, supports, or reinforces an intake or exhaust manifold relative to the cylinder head, engine block, or chassis.

It is NOT the manifold itself, and it is NOT the gasket or the studs/bolts that directly fasten the manifold to the head. Think of it as the "skeleton" that keeps the manifold from flexing, warping, or walking around under heat cycles and vibration.

Manifold brackets go by many names depending on the application:

- Manifold stay

- Manifold brace

- Turbo brace / support bracket

- Intake manifold support bracket

- Exhaust manifold brace

- Header brace

- Tial-style wastegate bracket

Regardless of the name, the core job is always the same: control movement and distribute loads so the manifold doesn't destroy itself or the fasteners.

Why Manifold Brackets Are Critically Important

They are the difference between a manifold that survives hundreds of cold-start to red-hot cycles and one that cracks within a single season. They carry loads that the primary gasket flange was never intended to handle alone. They control thermal expansion so the manifold grows and shrinks without fighting the cylinder head or the frame. They damp vibration before it turns into audible noise or fatigue. They keep heavy turbochargers from prying on turbine inlet flanges. In short, they protect the expensive parts by sacrificing themselves first when something has to give.

A missing or broken bracket turns a minor vibration into a major stress riser. Exhaust manifolds crack at the thin sections near the ports, intake manifolds split around injector bosses, and hydraulic manifolds tear mounting ears clean off. The bracket is the planned weak link that is cheap and easy to replace, while the manifold itself is cast, machined, and often ported at great expense.

In racing and heavy equipment the stakes are even higher. A bracket failure at full load can drop an exhaust manifold onto a header pipe, spike EGT, and grenade a piston in seconds. On a million-dollar mining truck, a failed hydraulic manifold bracket can shear valves, dump fluid, and shut the machine down for days.

Types of Manifold Brackets

- Exhaust Manifold Support Brackets The most familiar type. Usually a stamped or forged steel arm that bolts to a cylinder-head boss or water-pump stud on one end and captures a machined pad or boss on the manifold on the other.

- Intake Manifold Support Brackets Lighter duty but still critical on long plastic or magnesium intakes. They prevent the intake from rocking on its seals under boost pulsations and keep fuel rails from fatiguing.

- Turbocharger-to-Manifold Brackets These are often V-band or Marman clamp supports plus a three- or four-leg brace that ties the turbine housing back to the head or block. Porsche 991–997 Turbo and many diesel pickups use elaborate cast + machined stainless brackets for this.

- Hydraulic and Pneumatic Valve Manifold Mounting Brackets In mobile equipment you see heavy rectangular or channel-section brackets that bolt to the machine frame and provide ISO 6149 or CETOP mounting patterns for the valve banks. These brackets often incorporate vibration isolators and quick-release pins.

- Refrigeration and HVAC Manifold Support Frames Usually light-gauge galvanized or stainless cradles that prevent copper manifolds from transmitting compressor vibration into the cabinet skin.

Materials: What Actually Works

- Mild steel → fine for OEM replacement or very low-heat applications, but rusts quickly.

- 304 stainless → the default for most aftermarket braces. Decent strength, excellent corrosion resistance.

- 4130 chromoly → the choice when weight and maximum strength matter (1,000+ hp drag cars).

- 6061-T6 aluminum → only acceptable on intake side or very low-temp exhaust applications. Will melt or anneal above ~500 °C.

- Titanium → exotic, very expensive, mostly for weight-obsessed time-attack or bikes. Ti braces on a 2JZ making 2,000 hp look cool on Instagram but are structural overkill.

- Coatings: Ceramic coating or high-temp powder coat adds almost no strength but dramatically increases longevity by reducing oxidation and heat transfer to the bracket itself.

Design Considerations Most People Get Wrong

- Thermal expansion must be accounted for If your bracket is steel and bolts to an aluminum head with a steel manifold, the head grows ~0.0012 in/100 °C while the steel barely moves. A rigid bracket with no compliance will bend or snap studs. Solutions:

-

- Slot one hole oblong

- Use a spherical rod-end (heim joint)

- Add a sliding sleeve joint

-

- Never rely on the bracket to carry boost-load torque The bracket should only resist flex and vibration, not try to clamp the manifold to the head. That's the job of the studs and MLS gasket.

- Avoid single-shear lugs A single 10 mm bolt in single shear holding a 35 lb top-mount manifold will eventually ovalize the hole and fail.

- Welded bosses need reinforcement Simply welding a 1/4" tab onto a 0.065" schedule-10 runner is asking for cracks. Good manifold builders use gusseted "ears" or doubler plates.

Manufacturing Methods

High-volume OEM brackets are almost always progressive-die stamped from coil stock, robot-welded if multiple pieces are required, and then sent through a ferritic nitrocarburizing or aluminized coating line for corrosion protection.

Aftermarket and low-volume brackets start life as laser-cut blanks that are CNC press-brake formed and TIG welded by hand; the best shops use purge gas on the back side to keep the welds bright and scale-free.

Investment-cast stainless or nodular iron is the choice when the shape is too complex for stamping or when wall thickness needs to vary dramatically for weight optimization.

CNC machining from billet is common for prototypes and ultra-low volume runs, especially in aluminum or titanium.

Direct metal laser sintering (DMLS) and other additive processes are now in series production on cars that cost more than most houses; the brackets come out near-net-shape, topologically optimized, and impossibly light.

Maintenance and Inspection Tips

Check every bracket whenever the manifold is off the engine; cracks start small and hide in corners.

Look for elongated holes, shiny fretting surfaces, or missing bushings — all early signs of movement.

On exhaust brackets, a light brown or straw color is normal; deep blue or black means it has been seriously overheated and fatigue life is compromised.

Torque every fastener to spec in the correct sequence; uneven clamping distorts the bracket and preloads the manifold.

Replace any stainless fastener that shows galling or thread damage; seized studs are the fastest way to crack an aluminum head when you try to remove a bracket later.

Clean the mating surfaces; a single piece of old gasket material trapped under a bracket foot acts like a fulcrum and multiplies stress.

On sliding-slot designs, verify that the bracket can still move freely when cold; carbon buildup or corrosion can lock it solid and turn it into a rigid lever that will snap something the next time the manifold heats up.

Keep anti-seize on the threads and a thin smear of high-temp nickel paste on the contact faces of stainless-to-cast-iron interfaces.

In hydraulic systems, inspect brackets for impact damage and replace bent ones immediately; even a few millimeters of misalignment stacks valves and causes side loads that destroy spool bores.

The manifold bracket remains invisible until it fails, but it is doing quiet, critical work on every heat cycle, every mile, every load event. Treat it with the respect it deserves and it will protect the rest of your system for decades.

The manifold bracket may be a small component, but its significance in automotive performance cannot be overstated. By understanding the various types and their functions, you can make informed decisions that enhance your vehicle's efficiency and longevity. Whether you're a car enthusiast or a professional mechanic, recognizing the role of a quality manifold bracket is crucial. At Yuhuan JINYI Hardware Co., Ltd., we are committed to providing top-notch manifold brackets that meet the highest industry standards. With our expertise and dedication to quality, we ensure that every component contributes to the optimal performance of your vehicle. So, as you consider your next upgrade, remember the importance of choosing the right manifold bracket for your needs.

-

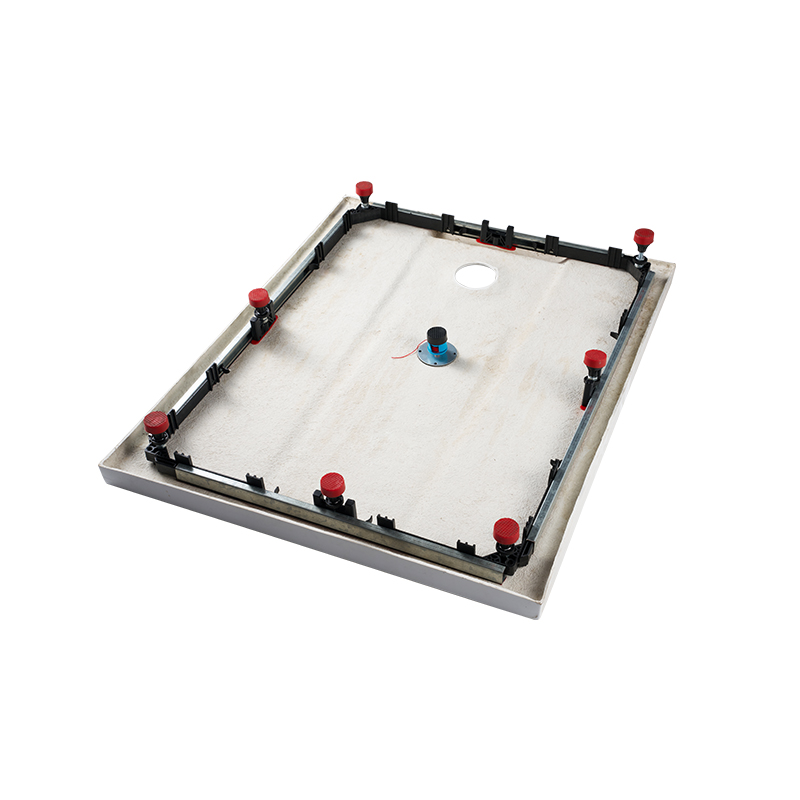

Where to Buy Shower Tray Frames from China?

Dec 03, 2025

When it comes to sourcing shower tray frames for international bathroom projects, finding a reliable Chinese manufacturer is essential. China has become the world’s leading hub for bathroom hardware production, offering high-quality products at competitive prices. But with so many suppliers available, where should you buy shower tray frames from China?

The answer is Yuhuan JINYI Hardware Co., Ltd. – a trusted name in the industry with over 30 years of manufacturing experience.

Why Choose JINYI Shower Tray Frames?

At JINYI, we specialize in producing durable, adjustable, and easy-to-install shower tray frames that are widely exported to Europe, North America, and other global markets.

Key Advantages:

Strong Load Capacity – Made from corrosion-resistant steel

Adjustable Design – Ensures perfect leveling for different bathroom floors

Fast Installation – Saves time for contractors and installers

OEM & ODM Services – Custom solutions for international brands

Competitive Pricing – Factory-direct supply with strict quality control

Trusted by International Bathroom Brands

One of JINYI’s strengths lies in OEM and ODM partnerships. We have supplied shower tray frames to leading bathroom companies in Europe, including a German partner who started with samples and quickly moved into continuous bulk orders after being impressed by our quality and precision manufacturing.

Applications of JINYI Shower Tray Frames

- Residential Bathrooms – Long-lasting and stable support

- Hotels & Commercial Projects – Reliable for heavy daily use

- Renovation Projects – Easy to fit and adjust in existing bathrooms

Whether you are a distributor, wholesaler, or contractor, JINYI offers the right solution for your shower tray installation needs.

Why Buy from JINYI in China?

- 30+ years of bathroom hardware manufacturing

- Located in Yuhuan, Zhejiang – China’s coastal manufacturing hub

- Advanced production and strict QC system

- Efficient global shipping and after-sales support

If you are wondering “Where to buy shower tray frames from China?”, look no further than JINYI. With our combination of quality, affordability, and customization, we are the trusted partner for international bathroom brands.

For more information, please visit: https://www.yh-jinyi.com

For inquiries or samples: WhatsApp +86 13750801289

-

How Does a Shower Tray Support Frame Improve Stability

Dec 01, 2025

What Are the Key Benefits of Using a Shower Tray Support Frame

A Shower Tray Support Frame plays an important role in ensuring the stability and durability of a shower installation. While the tray itself provides a surface for water drainage, the supporting structure beneath maintains level positioning, prevents shifting, and enhances overall longevity. For both residential and commercial bathrooms, choosing a reliable base system contributes to safe and lasting performance.

Enhanced Stability and Safety

One of the main advantages of this underlying support is improved stability. By evenly distributing weight across the tray, the base reduces the risk of sagging or movement. This stability helps prevent water pooling beneath the shower and minimizes stress on flooring materials, lowering the likelihood of cracks or damage over time.

Simplified Installation and Adjustments

Adjustable tray bases allow installers to fine-tune height and alignment with surrounding walls and fixtures. This flexibility simplifies work in spaces with uneven floors and ensures a proper fit without additional shimming. Reducing installation complexity saves time and labor while enhancing the overall precision of the bathroom setup.

Protection for Surrounding Structures

A solid tray foundation protects adjacent walls and flooring. Even distribution of weight reduces stress on tiles and prevents premature wear. This underlying support maintains integrity under daily use, preserving finishes and minimizing the chance of leaks or water damage.

Long-Term Durability and Maintenance

A properly designed base extends the lifespan of the tray. Resistance to bending, warping, and uneven stress reduces repair needs. Some systems also offer easy access for cleaning or inspection, allowing homeowners to address potential issues before they escalate.

Environmental and Cost Considerations

Modern tray bases are often constructed from durable metals, reinforced plastics, or composite materials that balance strength with efficient material use. A high-quality support system minimizes replacements, lowers maintenance costs, and contributes to sustainable bathroom installations.

Choosing the right structural support beneath a shower tray ensures stability, protects surrounding elements, and enhances long-term durability. A well-planned installation supports smooth operation, reduces maintenance, and delivers reliable performance for both homeowners and professionals.

Which Materials Make the Most Reliable Shower Tray Support Frame

Choosing the right materials for the structural base of a shower tray is crucial for long-term stability and performance. A well-designed support system relies not only on shape and alignment but also on the inherent strength, durability, and resistance of the components used. Selecting suitable materials ensures the installation remains secure, prevents warping or sagging, and protects surrounding surfaces from damage over time.

Metal Components for Strength

Metals such as galvanized steel or treated aluminum are commonly used because of their rigidity and ability to handle daily load without bending. These components provide a solid foundation, maintaining even weight distribution across the tray. Their resistance to moisture and moderate impacts makes them a dependable choice for both home and commercial bathrooms.

Reinforced Plastic Options

High-density plastics or polymer composites are favored for their lightweight properties combined with sufficient firmness. These materials resist corrosion and rust, making them particularly suitable for areas exposed to humidity. In addition, plastic components can simplify handling during installation while still supporting the tray effectively.

Composite Materials for Balanced Performance

Composite support systems blend multiple materials to achieve a balance between strength, stability, and design flexibility. By combining fibers, plastics, or other reinforcements, these systems can accommodate complex shapes or adjustable features without compromising load-bearing performance. This versatility allows manufacturers and installers to meet diverse installation needs efficiently.

Factors Affecting Material Choice

Beyond basic durability, several environmental and practical factors influence the selection. Moisture exposure, temperature variations, and floor type should guide which components are chosen. In spaces where regular inspections or maintenance are expected, materials that allow easy access and minimal wear are preferable.

Benefits of Thoughtful Material Selection

A support base constructed from appropriate materials reduces the risk of tray movement, protects flooring and surrounding structures, and extends the life of the shower system. Proper material choice also supports safer installation practices, simplifies future maintenance, and improves overall bathroom functionality.

Selecting materials with the right combination of strength, resistance, and adaptability ensures that the shower tray maintains alignment, stability, and durability for years of daily use. Thoughtful decisions in base construction contribute to safer and more efficient bathroom installations.

How Can Installation Techniques Affect Shower Tray Support Frame Performance

The way a shower tray base is installed plays a critical role in its long-term stability and efficiency. Even with high-quality components, improper installation can lead to uneven weight distribution, vibrations, or movement over time. Understanding key installation practices helps ensure that the tray remains secure, level, and functional for daily use.

Importance of Surface Preparation

Before positioning the support system, the subfloor must be clean, level, and firm. Uneven or unstable surfaces can create pressure points that reduce the tray's stability. Small adjustments such as leveling shims or reinforcement plates can distribute weight evenly and prevent sagging.

Fastening and Alignment Considerations

Correct attachment of supports is essential to maintain uniform load distribution. Using compatible fasteners that match the material properties of the base prevents loosening or shifting under repeated use. Maintaining straight horizontal and vertical alignment ensures that the tray sits flat, reducing stress on edges and joints.

Environmental Factors During Installation

Moisture, temperature variations, and vibration from nearby plumbing or mechanical systems can influence base performance. Protective coatings, sealing, or vibration-dampening inserts help improve resilience and reduce the risk of long-term deformation. In areas with higher humidity, choosing fasteners and support components that resist corrosion further prolongs system reliability.

Adjustable Support Options

Some modern systems feature adjustable legs or modular supports, allowing fine-tuning of height and angle. This flexibility is valuable in uneven floors or complex bathroom layouts. Adjustable components also reduce the need for cutting or custom fitting, saving time during installation while maintaining performance standards.

Practical Tips for Consistent Results

- Verify floor level before beginning installation

- Use materials and fasteners suited for the environment

- Check alignment during and after assembly

- Leave space for slight movement to absorb stress

- Inspect regularly during early use to catch potential issues

Proper installation techniques are as important as material choice in ensuring a stable and long-lasting shower tray system. Attention to surface preparation, alignment, fastening, and environmental considerations helps maintain performance, reduce maintenance, and support daily usability.

-

Which Water Meter Bracket Works Best for Modern Building Systems

Nov 28, 2025

What Materials Are Commonly Used for a Durable Water Meter Bracket

A water meter bracket is a small yet essential support component that helps hold measuring devices securely in place during use. Although it may look simple, choosing the right material determines how well it performs in demanding conditions. Different environments, such as outdoor installations or locations exposed to moisture, require brackets that can stay stable without bending or corroding.

One commonly used option in this field is metal. It is widely selected because it brings consistent strength for everyday installation projects. Metals like treated steel or alloys can endure exposure to rainwater, ground moisture, or mild impact during maintenance work. These properties make it suitable for residential, commercial, and light industrial settings where reliability is essential.

Another material often used for a water meter bracket is reinforced plastic. It is appreciated for being lightweight while still offering the necessary firmness to hold equipment securely. Plastic brackets may be found in indoor installations or areas where exposure to chemicals needs to be minimized. Their resistance to rust is a notable benefit in environments where metal corrosion may be a concern.

In some projects, composite materials are introduced to enhance both performance and cost balance. These materials combine multiple elements to create a bracket that supports load requirements while maintaining stability over extended periods. Composites may offer design flexibility, allowing shapes that are difficult to produce with standard metals or plastics.

Choosing a material should not be based solely on price or appearance. Instead, the decision should take into account installation environment, exposure to water, the weight of the device it supports, and the expected frequency of inspections. When installers and suppliers evaluate these factors carefully, the selected bracket can serve its purpose without unexpected issues during operation.

In modern infrastructure systems, the importance of choosing a reliable water meter bracket is often underestimated. However, proper material choice reduces unexpected maintenance, supports accurate readings, and contributes to a stable measuring system. Whether it is metal, reinforced plastic, or composite, the goal remains the same, supporting consistent and safe application in water measurement systems.

How Installation Methods Affect the Stability of Water Meter Brackets

The way a water meter bracket is installed plays a significant role in its durability and long-term stability. Even when the bracket is made from a sturdy material, poor installation practices can reduce its performance, especially when the device is exposed to vibration, mechanical pressure, or outdoor conditions. Understanding how the installation process influences strength helps ensure a reliable setup for residential, commercial, or industrial systems.

Why Proper Mounting Technique Matters

Incorrect mounting can create uneven stress points where the bracket meets the wall or pipe support. Instead of distributing load evenly, misalignment causes unnecessary strain over time. This can lead to loosening, twisting movement, or surface corrosion in humid environments. In contrast, a balanced installation helps the bracket retain its shape and supports the meter efficiently.

Key Installation Considerations

Different factors influence how securely a bracket holds its place. Below are installation considerations that contribute to performance.

Installation Factor Impact on Stability Surface Type Rough or weak surfaces reduce grip and increase wobbling Fastener Quality Poor fasteners may loosen under vibration Alignment Accuracy Misalignment affects balance and long-term durability Support Position Incorrect height or direction influences load distribution Environmental Exposure Moisture and chemicals affect metal longevity How Environment Influences Mounting Choices

Temperature shifts, precipitation, dust, and chemical presence can change the performance of mounting hardware. Indoor installations may require fewer protective steps, while outdoor systems benefit from corrosion-resistant coatings or sealed fasteners. Moisture control and drainage spacing also help maintain stability by reducing rust risk at contact points.

Simple Practices to Improve Installation Reliability

Small adjustments during installation can have a noticeable impact on bracket stability. These steps reduce unwanted movement and support meter accuracy.

- Ensure that the base surface is clean and firm before mounting

- Use fastening components that match the bracket's material

- Maintain straight horizontal and vertical alignment to avoid off-angle pressure

- Leave enough clearance to minimize vibration transmission from piping

A reliable system does not rely only on the strength of the bracket material. Installation quality makes a noticeable difference in how long the device remains secure. Understanding how alignment, surface selection, and fastening methods affect performance allows installers and users to maintain stable conditions without frequent adjustments. By focusing on these techniques, water meter brackets can perform as expected under diverse working environments.

Why Building Projects Require the Right Type of Water Meter Bracket

Water supply facilities rely on reliable support components during construction, and the water meter bracket plays an important role in ensuring proper placement of measuring devices. Selecting an appropriate bracket type does not only involve physical strength, but also how it interacts with building structure, pipe layout, and long-term usage. Every building environment has different conditions, which means a suitable support solution helps minimize unnecessary adjustments later.

During the planning stage of a construction project, engineers consider how the bracket will handle pressure caused by plumbing connections and external forces. A weak or incompatible support base could lead to loose fittings, inaccurate readings, or pipe misalignment. These issues may not surface immediately, yet they can influence measurement accuracy and maintenance frequency over time. By matching bracket types with specific building materials, installers help support more stable meter operation.

Different water supply systems require diverse installation directions. Wall-mounted brackets might suit compact indoor spaces, while ground-fixed options are better for outdoor meters exposed to environmental factors. Structural density, humidity, vibration level, and service accessibility all influence which style is more practical. When the selected bracket fits these requirements, technicians spend less time modifying the location and more time finalizing connections.

Choosing a suitable bracket also encourages safer working conditions. When the meter has a secure and balanced base, the connecting pipes experience less strain, reducing the likelihood of unexpected damage during future maintenance. Stable support allows workers to inspect or replace components without dealing with unstable fixtures. This enhances installation convenience and reduces repair interruptions on active sites.

To illustrate how bracket selection affects planning decisions, the table below compares different usage scenarios.

Building Scenario Appropriate Bracket Consideration Main Benefit Indoor meter rooms Wall-supporting models Saves space and keeps pipes aligned Outdoor public areas Ground-mounted or reinforced types Withstands weather exposure High-vibration facilities Shock-absorbing structures Reduces connection looseness Elevated platforms Adjustable brackets Simplifies alignment and leveling Proper selection contributes to structural reliability as buildings age. Designing with the right bracket at the beginning of a project limits unnecessary reinforcement after installation. Whether used in residential complexes or commercial systems, a fitting bracket helps maintain consistent readings, reduces disruptions, and supports easier maintenance routines for operators.

By considering physical environment, load capacity, and accessibility needs, building professionals make informed decisions that enhance the useful life of water meter setups. A carefully chosen bracket may seem like a minor detail, but it adds long-term value to construction planning and routine service tasks.

Which Water Meter Bracket Designs Support Safer Pipeline Layouts

Creating a secure pipeline layout requires careful consideration of the components that hold pipes in place. Among these parts, the water meter bracket plays a key role in maintaining alignment, distributing weight, and reducing strain on connected pipelines. Design features can influence how well each installation adapts to changing pressures, temperature differences, and environmental environments.

Design Features That Improve Pipe Support

A bracket with an expanded contact surface often provides a smoother structural transition between the meter and the pipeline. When weight is shared across a broader area, the connected pipes experience reduced bending forces. In applications where frequent vibration occurs, this form of support can help keep measuring devices from shifting out of position. Another design feature involves reinforced side structures that limit twisting movements caused by unequal water flow or sudden pressure variations.

Benefits of Adjustable Structures

Adjustable models help builders fine-tune elevation, direction, or spacing according to the layout of the pipeline. When a project demands precise orientation, being able to modify height or angle helps avoid pipe distortion. This can be valuable in crowded installation spaces, where interference with nearby components is a concern. Adjustment mechanisms also reduce installation time, since fewer custom fabrication steps may be required on site.

Comparison of Common Design Options

Design Style Typical Feature Project Advantage Fixed Structure Stable frame without movement Suitable for predictable layouts Adjustable Form Height or angle modification Helps fit complex spaces Reinforced Build Extra support segments Useful for vibration-heavy areas Each option serves a different type of installation need, which means selection depends on pipe location, pressure conditions, and the structural demands of the building.

Considering Installation Environments

When choosing a design, construction teams must also pay attention to climate, vibration exposure, and available mounting surfaces. In locations with frequent temperature changes, a design supporting gradual expansion and contraction is often considered valuable. Meanwhile, systems installed near machinery or pumps may benefit from stronger frames to resist shaking forces.

The Design Decision and Project Safety

A suitable bracket design affects not only stability but also long-term maintenance planning. A model that limits pipe movement can reduce the chance of leaks forming at joint connections. Selecting a design that matches building conditions makes it easier to maintain dependable flow readings and reduces the need for frequent corrections.

Tips for Selecting Water Meter Brackets for Commercial and Residential Use

Choosing water meter brackets for housing areas and business environments requires looking beyond basic pipe support. Different locations face varied loads, exposure, and installation challenges, so suitable choices can improve functionality and installation quality without relying on excessive reinforcement.

One of the first considerations involves understanding how the pipeline will sit in the intended layout. Brackets designed for straight sections, floor-mounted setups, or wall-supported positions each serve different structural needs. For residential areas, compact forms can simplify placement behind cabinets or outdoor meter boxes. In commercial zones, additional spatial allowance often demands wider bracket spacing and forms that offer better alignment with main lines.

Material choices also influence performance in specific environments. For outdoor installations, moisture resistance matters, while interior installations may benefit from designs that accommodate quick adjustments during construction. Some brackets support dual or multi-unit configurations, allowing multiple meters to share structural support without cluttering limited areas.

Below is a simple comparison showing different application focuses.

Usage Environment Important Consideration Potential Benefit Residential area Smaller structures Easy placement in tight locations Commercial building Wider layout Better line organization Outdoor utility zone Environmental exposure Increased adaptability Indoor pipeline network Adjustment needs Improved installation flexibility Installation habits also influence selection. Regions that require frequent meter inspection may benefit from brackets that allow clear visibility or straightforward disassembly. Space optimization is another factor because some modern construction practices favor hidden meter placements, requiring forms compatible with compact housings.

Finally, coordination with project designers or plumbers helps ensure the chosen bracket fits the pipeline plan rather than forcing workers to alter the layout. A suitable choice respects installation practices, site conditions, and future maintenance needs, helping construction teams work efficiently while maintaining structural order.

-

Shower Tray Feet vs. Concrete Base: Which Installation Method Works Best?

Nov 26, 2025

When it comes to bathroom construction, the foundation of your shower tray is one of the most important decisions you’ll make. A strong, stable base ensures not only the safety of users but also the long-term durability of the entire shower system. Traditionally, many builders have relied on a concrete base to support shower trays. However, in recent years, adjustable shower tray feet have become a popular alternative across Europe and beyond.

Concrete Base: The Traditional Method

For decades, pouring a concrete base has been the go-to solution for shower tray installation. It involves creating a solid layer of mortar or cement underneath the tray to keep it fixed in place.

Advantages of a Concrete Base:

Strong foundation: Provides excellent load-bearing capacity.

Solid feel underfoot: Some homeowners prefer the firmness of a concrete-supported shower tray.

Durable in the long term: When done properly, it can last for many years.

Limitations of a Concrete Base:

Labor-intensive installation: Requires mixing, pouring, and leveling, which can be time-consuming.

No height adjustability: Once installed, the tray cannot be repositioned or adjusted easily.

Moisture concerns: If the sealing isn’t perfect, water infiltration can cause cracks or mold issues over time.

Difficult repairs: Any modification or repair often requires breaking the concrete layer.

While the concrete base remains a solid choice for certain construction styles, it often lacks flexibility for modern bathroom requirements.

Shower Tray Feet: The Modern Solution

Adjustable shower tray feet are engineered support systems designed to simplify installation while enhancing stability. These feet are typically made of strong metal or reinforced plastic, with adjustable height features to ensure a perfectly level tray on any surface.

Advantages of Shower Tray Feet:

Quick installation: No need to wait for concrete to cure; the tray can be installed in hours instead of days.

Height adjustability: Each foot can be adjusted individually to compensate for uneven floors.

Easy access: The hollow space beneath the tray allows for convenient pipe routing and future maintenance.

Lightweight and flexible: Perfect for renovation projects where adding concrete weight isn’t ideal.

Cost-efficient in the long run: Less labor time and easier maintenance reduce overall project costs.

Limitations of Shower Tray Feet:

Initial material cost: May be slightly higher than raw cement, though offset by labor savings.

Requires proper sealing: As with any installation, ensuring waterproof sealing is essential

With CE-certified shower tray feet, modern installers achieve both flexibility and safety while meeting European standards.

Which One Works Best?

The choice between concrete base and shower tray feet depends largely on the project requirements:

For traditional, permanent installations: Concrete base can provide a sense of sturdiness but sacrifices flexibility.

For modern, efficient, and professional projects: Shower tray feet are the superior choice, especially for contractors who value adjustability, time savings, and long-term serviceability.

In Europe, professional installers increasingly prefer shower tray feet for both residential and commercial bathrooms. They not only speed up construction but also simplify maintenance—something that matters greatly to hotels, apartments, and high-traffic projects.

Why Choose JINYI Shower Tray Feet?

As a CE-certified manufacturer with over 30 years of experience, JINYI specializes in bathroom and plumbing hardware, including adjustable shower tray feet. Our products are designed for strength, durability, and easy installation, making them ideal for distributors, wholesalers, and builders worldwide.

What sets JINYI apart?

OEM & ODM expertise: We customize solutions to meet your specific project needs.

Factory-direct pricing: Located near Ningbo Port, we provide cost-effective production and fast delivery.

Consistent quality: With strict quality control and CE certification, you can trust every shipment.

Global reach: JINYI exports to Europe, North America, and other regions, supporting international projects with reliable hardware.

While both concrete bases and shower tray feet have their place in bathroom construction, the modern choice for efficiency, flexibility, and professional results is clear: adjustable shower tray feet. They save time, reduce labor costs, and provide a practical solution for installers and end-users alike.

If you’re looking for reliable, CE-certified shower tray feet from an experienced manufacturer, JINYI is here to support your business with quality products and professional service.

For more information, please visit: https://www.yh-jinyi.com

For inquiries or samples: WhatsApp +86 13750801289

-

How to Choose a Shower Tray Support Frame

Nov 24, 2025

What to Consider When Choosing a Shower Tray Support Frame

Shower tray support frames play a crucial role in bathroom installations by ensuring the tray remains stable, level, and secure. Selecting the right frame is essential not only for durability but also for preventing leaks, uneven surfaces, and long-term maintenance issues. This guide explores practical considerations for choosing a shower tray support frame that meets both functional and environmental needs.

Understanding the Role of a Shower Tray Support Frame

A shower tray support frame provides the foundation for the tray, distributing weight evenly and maintaining proper alignment. Without a solid frame, trays may warp, shift, or stress plumbing connections over time. Proper support enhances user safety, preserves the integrity of surrounding structures, and ensures a smooth installation process.

Material Selection

The material of a support frame directly impacts its longevity, strength, and resistance to moisture. Common options include:

- Metal Frames: Typically made of steel or aluminum, metal frames offer strong support and resist deformation under heavy loads. Protective coatings can improve corrosion resistance in humid environments.

- Plastic or Polymer Frames: Lightweight and corrosion-resistant, these frames are easier to handle and suitable for residential bathrooms with standard trays. They may be less ideal for very heavy or large trays.

- Composite Frames: Combining metal and reinforced polymers, composite frames provide a balance of strength and moisture resistance while remaining relatively lightweight.

When selecting a material, consider environmental conditions, tray size, and expected load to ensure long-lasting performance.

Size and Compatibility

A frame must match the shower tray dimensions accurately. Incorrect sizing can lead to uneven support, gaps between the tray and frame, or instability during use. Check manufacturer specifications for tray dimensions, recommended frame types, and any adjustable options that allow fine-tuning during installation.

Installation and Adjustability

Frames with adjustable heights or modular components provide greater flexibility during installation. This feature can help accommodate floor level variations, plumbing layouts, or specific bathroom designs. Consider frames that include clear instructions and easy mounting features to reduce installation errors and save time.

Load Capacity and Stability

The support frame should be capable of handling the combined weight of the tray, water, and user safely. Evaluate frames for:

- Even weight distribution across all support points

- Resistance to bending, warping, or shifting under pressure

- Compatibility with additional reinforcement options, if needed

Proper load management prevents long-term damage and enhances safety.

Moisture Resistance and Maintenance

Bathrooms are high-humidity environments, making moisture resistance a critical factor. Materials that resist corrosion, mold, or water absorption reduce maintenance requirements and extend the life of the frame. Frames designed with easy-to-clean surfaces or removable components can further simplify upkeep.

Cost and Sourcing

While cost is important, balance price with material quality, stability, and durability. Choosing a frame solely based on lower cost may compromise safety and longevity. Consider local availability and warranty options to ensure a reliable purchase.

Selecting the right shower tray support frame requires careful attention to material, size, adjustability, load capacity, and moisture resistance. By evaluating these factors, manufacturers, contractors, and homeowners can ensure a safe, durable, and efficient bathroom installation.

A well-chosen support frame not only stabilizes the shower tray but also contributes to consistent performance and reduced maintenance over time, protecting both the plumbing system and bathroom surfaces.

How Shower Tray Support Frames Improve Bathroom Stability

Shower tray support frames are an essential part of a stable and durable bathroom installation. Beyond simply holding the tray in place, these frames contribute to structural integrity, evenly distribute weight, and reduce long-term maintenance issues. Understanding the ways support frames enhance stability helps homeowners and contractors make informed decisions.

Even Weight Distribution

A properly installed support frame ensures that the shower tray's weight is spread evenly across the floor. Uneven support can cause trays to bend or sag, which may lead to cracks, water leakage, or damage to surrounding tiles. Frames with multiple support points or adjustable legs allow for precise leveling, reducing stress on the tray and maintaining a flat surface.

Enhanced Tray Alignment

Shower tray support frames help maintain correct alignment between the tray and plumbing connections. Misalignment can cause water pooling, leaks, or strain on pipes. Frames designed with adjustable height or modular sections make it easier to achieve precise placement, ensuring both functional and aesthetic alignment in the bathroom.

Vibration Reduction

Daily use of a shower can produce vibrations that may shift trays or loosen connections over time. Support frames with secure mounting and solid construction minimize movement, keeping trays stable and preventing noise or wobbling. Reducing vibration also protects pipes and seals from premature wear.

Load Support for Safety

Support frames are designed to hold the combined weight of the tray, water, and users safely. Choosing frames with adequate strength prevents deformation or instability under pressure. Some frames incorporate reinforced sections or cross-bracing to further increase load capacity, offering peace of mind in high-use bathrooms.

Moisture and Environmental Considerations

Bathrooms are humid environments, and prolonged exposure to water can affect both trays and supporting structures. Frames made from moisture-resistant materials such as treated metals, polymers, or composites maintain stability over time. Proper material selection reduces corrosion, prevents weakening of structural elements, and ensures the tray remains secure.

Maintenance and Longevity

A stable frame contributes to long-term maintenance benefits. Frames that prevent movement or sagging reduce wear on trays, seals, and surrounding tiles. Additionally, modular or easily adjustable frames simplify inspections, cleaning, and future repairs without dismantling the entire installation.

Example Overview of Stability Benefits

Benefit Description Impact on Bathroom Weight distribution Spreads load evenly across floor Reduces tray bending or sagging Tray alignment Keeps tray level and aligned with plumbing Prevents leaks and water pooling Vibration reduction Minimizes movement during use Protects pipes and seals Load support Handles combined weight of tray and users Ensures safety and stability Moisture resistance Uses corrosion-resistant materials Extends frame and tray life Maintenance-friendly Modular or adjustable design Simplifies inspection and cleaning Shower tray support frames are more than simple brackets—they are foundational elements that improve bathroom stability, safety, and longevity. By distributing weight, reducing vibration, maintaining alignment, and resisting moisture, these frames protect the shower tray and surrounding structures.

Selecting and installing a suitable support frame ensures a reliable and low-maintenance bathroom, providing peace of mind for homeowners and efficiency for contractors.

Why Using a Quality Shower Tray Support Frame Protects Your Flooring

A shower tray support frame plays a crucial role not only in stabilizing the tray but also in safeguarding the underlying flooring. Poorly supported trays can transmit weight unevenly, cause water leakage, or damage tile and subfloor materials. Using a reliable frame ensures that floors remain protected while maintaining the overall integrity of the bathroom installation.

Preventing Sagging and Structural Damage

When a tray lacks adequate support, the floor beneath may experience excessive stress. Over time, this can lead to sagging, cracks in tiles, or even damage to wooden subfloors. A sturdy frame distributes weight evenly across the installation area, reducing the risk of structural deformation and extending the lifespan of both the tray and the floor.

Reducing Water Leakage Risk

Misaligned or unsupported trays can create gaps where water seeps into the subfloor. Continuous moisture exposure can weaken flooring materials, promote mold growth, and increase maintenance costs. Support frames maintain proper tray positioning, ensuring that all edges and seals remain tight. This alignment reduces the chance of leaks, keeping the floor dry and secure.

Enhancing Tray Stability

Daily use of a shower exerts repeated forces on the tray. Without a supportive frame, even slight movement can create stress points on tiles or joints beneath the tray. A high-quality support frame minimizes movement, absorbs vibrations, and stabilizes the tray during use. By maintaining stability, the flooring stays protected and the bathroom environment remains safe.

Compatibility with Various Floor Types

Different bathroom floors require different levels of support. Concrete, wooden, or composite subfloors can respond differently under weight and moisture. Frames designed with adjustable height or modular support points allow for precise leveling, ensuring that the tray sits evenly and prevents uneven pressure on any part of the floor.

Longevity and Maintenance Benefits

Investing in a durable frame simplifies long-term maintenance. Floors are less likely to develop cracks or water damage, reducing the need for repairs or replacements. Additionally, frames that allow for easy adjustments and inspection make it simpler to monitor the tray and subfloor condition, ensuring ongoing protection for the flooring.

Example Overview of Flooring Protection Benefits

Feature Description Flooring Impact Even weight distribution Spreads load across subfloor Reduces sagging and cracks Leak prevention Maintains tray alignment and seal integrity Protects subfloor from moisture damage Vibration absorption Stabilizes tray during use Minimizes stress on flooring Adjustable support points Compatible with multiple floor types Ensures even pressure and prevents damage Easy maintenance Simplifies inspection and adjustments Extends flooring lifespan A quality shower tray support frame safeguards the flooring by distributing weight evenly, preventing leaks, reducing vibrations, and accommodating different floor types. Proper installation and use of these frames ensure a safe, stable, and low-maintenance bathroom.

Protecting the subfloor is as important as securing the tray itself, and a well-designed support system ensures both long-lasting performance and peace of mind for homeowners and contractors alike.

-

How Can a Water Meter Bracket Be Installed Safely

Nov 21, 2025

How to Install a Water Meter Bracket Safely and Efficiently

Water meter brackets are essential components in plumbing systems, providing secure support for water meters and ensuring stable connections. Installing these brackets correctly is important for preventing leaks, maintaining accurate measurements, and extending the service life of the plumbing setup. This guide outlines practical steps and considerations to achieve a safe and efficient installation.

Understanding the Purpose of a Water Meter Bracket

Before installation, it is important to understand why water meter brackets are necessary. These brackets hold the water meter in place, preventing movement that could damage pipes or connections. Proper support ensures accurate readings and reduces the risk of costly repairs in the future.

Choosing the Right Location

Selecting an appropriate location is the first step in a successful installation. The bracket should be positioned where the meter is easily accessible for reading and maintenance. Avoid areas with excessive vibration, moisture accumulation, or obstacles that may interfere with pipe alignment.

Careful location planning also ensures compliance with local plumbing regulations and helps avoid potential interference with other utilities.

Preparing the Installation Area

A clean, stable surface is key for mounting the bracket. Remove debris, dust, or any loose materials around the installation site. Ensuring a flat and stable surface allows the bracket to sit securely, which reduces stress on the pipes and water meter.

Marking the exact positions for screws or fasteners before drilling can save time and prevent errors during installation.

Mounting the Bracket

Begin by aligning the bracket with the marked positions. Use appropriate fasteners for the surface material, such as wall anchors for concrete or screws for wood. Ensuring the bracket is level and firmly secured is critical for stability.

Double-check the alignment with the pipe before final tightening. Misalignment can lead to strain on joints and connectors, which may affect meter accuracy or cause leaks over time.

Connecting the Water Meter

Once the bracket is secured, carefully attach the water meter. Ensure that the meter is fully supported by the bracket and that no weight is resting solely on the pipes.

Verify that all connections are tight, leak-free, and properly aligned. Proper support reduces the chance of mechanical stress on fittings and maintains smooth water flow.

Safety Considerations

While installing a water meter bracket, always follow basic safety practices:

- Wear protective gear, such as gloves and safety glasses.

- Avoid working near live electrical sources.

- Use appropriate tools to prevent damage to the bracket or surrounding surfaces.

- If unsure about local plumbing codes or standards, consult a professional.

These precautions help prevent accidents and ensure a durable installation.

Maintaining Your Installation

After installation, regular inspection of the bracket and water meter can prevent long-term issues. Check for loose fasteners, signs of corrosion, or any movement in the bracket.

Routine maintenance extends the life of both the bracket and the water meter, ensuring reliable performance over time.

Installing a water meter bracket safely and efficiently requires proper planning, correct positioning, careful mounting, and adherence to safety standards. By following these steps, manufacturers, contractors, and homeowners can ensure that water meters remain stable, accurate, and durable.

A well-installed bracket not only protects plumbing systems but also contributes to consistent water measurement and smooth operation.

Which Materials Make the Most Reliable Water Meter Brackets

Choosing the right material for a water meter bracket is a key step in ensuring a stable and long-lasting plumbing setup. The material affects durability, resistance to corrosion, weight support, and overall performance. By understanding the characteristics of different options, manufacturers, contractors, and homeowners can select brackets that meet both functional and environmental requirements.

Metal Brackets

Metal brackets, such as those made from steel or aluminum, are widely used due to their strength and durability. They provide robust support for water meters and can handle moderate to heavy pipe loads without deformation.

Advantages of metal brackets include:

- High load-bearing capacity

- Resistance to bending under weight

- Compatibility with various mounting surfaces

Potential considerations involve preventing corrosion, particularly in moist environments. Using protective coatings or stainless alloys can help extend service life.

Plastic and Polymer Brackets

Plastic or polymer brackets are lightweight and easy to install. They are often chosen for residential applications or areas where corrosion resistance is a priority.

Key benefits include:

- Resistance to moisture and rust

- Flexibility in design and shape

- Easier handling and installation

While they may not support very heavy pipes as well as metal, modern polymer composites provide sufficient strength for standard water meter setups and reduce maintenance concerns.

Composite Brackets

Composite brackets combine materials such as reinforced plastic with metal inserts. This hybrid design provides a balance between strength, corrosion resistance, and installation flexibility.

Advantages include:

- Adequate load capacity

- Reduced risk of corrosion compared to all-metal options

- Durability for long-term use in varying environments

Composites can be tailored for specific needs, offering both reliability and adaptability in residential and commercial installations.

Considerations for Material Selection

When selecting a water meter bracket material, several factors should guide the decision:

- Environment – Moisture, temperature fluctuations, and chemical exposure affect longevity.

- Load Requirements – The weight of pipes and meters determines the necessary strength.

- Maintenance Needs – Materials that resist rust or corrosion reduce upkeep.

- Installation Ease – Lighter materials may simplify handling and positioning.

- Cost and Availability – Budget constraints and local sourcing influence choices.

Comparison Table of Common Bracket Materials

Material Strength Corrosion Resistance Ease of Installation Suitable Applications Steel High Moderate (coating recommended) Moderate Industrial, heavy-duty setups Aluminum Medium High Moderate Residential or moderate load Plastic / Polymer Low to Medium Very High Easy Residential, indoor use Composite Medium High Moderate Mixed residential and commercial Selecting the right material for water meter brackets is essential for stable and durable installations. Metals offer strength, plastics provide corrosion resistance and ease of installation, and composites balance both qualities.

By evaluating environmental conditions, load requirements, and maintenance expectations, users can choose brackets that ensure safe, reliable support for water meters over time. Proper material selection contributes to a smooth, low-maintenance plumbing system and enhances the longevity of both brackets and meters.

What Factors Affect the Durability of a Water Meter Bracket

Water meter brackets play a crucial role in plumbing systems by providing secure support and maintaining the proper alignment of water meters. The durability of these brackets is influenced by several factors, which can impact the longevity and reliability of both the bracket and the connected pipes. Understanding these factors helps manufacturers, contractors, and homeowners select and maintain brackets that perform well over time.

Material Quality

The material used for a water meter bracket is one of the most important factors affecting durability. Brackets made from strong metals or reinforced polymers generally withstand wear and stress better than low-quality materials.

- Metal brackets offer high structural integrity but may require protective coatings to resist corrosion.

- Plastic or polymer brackets are less prone to rust but may deform under excessive weight or impact.

- Composite designs combine multiple materials to balance strength and resistance to environmental factors.

Choosing the appropriate material for the installation environment is essential for long-term performance.

Environmental Conditions

Exposure to moisture, temperature changes, and chemicals can significantly affect bracket life. Brackets installed in humid or outdoor locations may be more prone to corrosion or material degradation.

Key environmental factors include:

- Humidity and water contact

- Seasonal temperature variations

- Exposure to cleaning agents or plumbing chemicals

Proper material selection and protective measures can help reduce the effects of environmental stress.

Installation Practices

Even the strongest bracket can fail if installed incorrectly. Factors related to installation that affect durability include:

- Proper alignment and leveling of the bracket

- Secure fastening to a stable surface

- Avoiding excessive force that may stress the bracket or pipes

Following recommended installation steps ensures the bracket maintains its integrity and supports the water meter effectively.

Load and Usage

The weight of the water meter and connected pipes, along with any additional forces, affects the longevity of the bracket. Heavy loads, vibration, or frequent movement may weaken the structure over time.

Considerations include:

- Supporting weight evenly across the bracket

- Minimizing stress on joints and connectors

- Accounting for potential expansion or contraction of pipes

Monitoring load distribution helps prevent premature wear or damage.

Maintenance and Inspection

Regular inspection and maintenance extend the life of a water meter bracket. Checking for signs of corrosion, loose fasteners, or cracks allows early intervention before major issues develop.

Maintenance tips include:

- Tightening loose screws or anchors

- Cleaning debris or sediment from mounting areas

- Replacing worn or damaged components promptly

A proactive approach to upkeep ensures reliable performance and prevents unexpected failures.

The durability of a water meter bracket depends on material selection, environmental exposure, installation quality, load management, and regular maintenance. By understanding these factors, manufacturers and users can make informed choices that enhance reliability and longevity.

A well-chosen and properly maintained bracket not only supports the water meter effectively but also contributes to the overall efficiency and safety of the plumbing system.

-

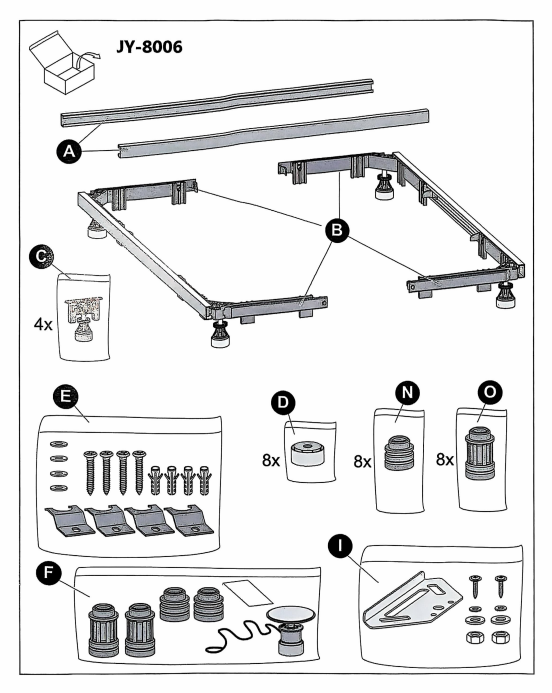

How to Install a Shower Tray Frame Step by Step

Nov 19, 2025

Installing a shower tray correctly is essential for ensuring stability, durability, and waterproof performance in your bathroom. The JINYI Shower Tray Frame 8006 is designed to make installation easier, faster, and more reliable. In this step-by-step guide, we'll walk you through the process of installing the 8006 frame like a professional.

Why Choose the JINYI 8006 Shower Tray Frame?

The JINYI 8006 model is a high-quality adjustable support frame for shower trays. Made from durable steel with anti-corrosion treatment, it offers:

Strong load-bearing capacity

Adjustable legs for perfect leveling

Quick assembly structure

Long-lasting stability

This makes it an ideal choice for residential bathrooms, hotels, and renovation projects.

Tools You Will Need

Before starting, prepare the following tools:

Electric drill

Screwdriver

Tape measure

Spirit level

Adjustable wrench

Step-by-Step Installation Guide

- Prepare the Area

Make sure the bathroom floor is clean, level, and dry. Measure the dimensions of your shower tray to confirm the correct frame size.

- Assemble the Frame

Lay out all the frame parts of the 8006 model. Connect the side bars and corner joints using screws provided in the package. Ensure the frame is square and secure.

- Attach Adjustable Legs

Install the adjustable support legs onto the frame. Tighten them with a wrench, but leave enough room for later height adjustment.

- Place the Frame in Position

Move the assembled frame to the installation area. Use a spirit level to check the alignment. Adjust the legs until the frame is perfectly level.

- Fix the Frame to the Floor

Once leveled, drill pilot holes in the marked positions and secure the frame with screws and expansion plugs. This ensures the shower tray frame stays firm and stable.

- Install the Shower Tray

Carefully place the shower tray onto the frame. Double-check the level and stability. Apply sealing around the edges to ensure waterproof protection.

Final Tips

Always double-check measurements before drilling.

Do not overtighten screws to avoid damaging the frame.

Use professional sealing materials for long-lasting waterproofing.

Conclusion

Installing the JINYI Shower Tray Frame 8006 is straightforward with the right tools and careful steps. With its durable steel construction and adjustable design, the 8006 model provides the perfect solution for both DIY users and professional contractors.

For more information, please visit: https://www.yh-jinyi.com

For inquiries or samples: WhatsApp +86 13750801289

-

How Can You Ensure a Stable and Safe Shower Base

Nov 17, 2025

Bathroom Stability: Installation Methods for Shower Bases Support Frames

In contemporary bathroom design, ensuring stability, hygiene, and long-term reliability is paramount. A Shower Bases Support Frame plays a crucial role in achieving these goals, providing the structural foundation necessary for maintaining the alignment, safety, and performance of the shower system. While often unseen, the frame determines how weight is distributed, plumbing connections are aligned, and maintenance can be carried out efficiently. Selecting the appropriate installation method is essential, as different approaches suit varying base types, flooring materials, and bathroom layouts.

Preparing the Floor and Assessing Subfloor Conditions

Successful installation begins with a thorough evaluation of the subfloor. Bathrooms may feature a variety of flooring types, including concrete slabs, wooden joists, or composite panels. Each material interacts differently with the support frame. A level, stable surface is critical for distributing weight evenly and preventing stress points that could cause movement or damage to the shower tray. Uneven or sloped floors may necessitate the use of adjustable legs or shims to achieve proper alignment. Taking the time to assess the subfloor ensures the foundation for a safe and long-lasting installation.

Securing the Frame: Fasteners vs Adhesive

Once the subfloor is prepared, the frame must be anchored securely. Installation options generally include mechanical fasteners or adhesive methods. Fasteners offer rigid support, often preferred in commercial settings where heavy loads or high-traffic usage demand maximum stability. Adhesive-based installation, meanwhile, is practical for residential spaces where drilling may damage tiles or subflooring. Adhesives can provide reliable support while minimizing disruption to the surrounding area.

Regardless of the chosen method, proper anchoring ensures the frame remains fixed under daily use. A stable foundation prevents tray movement, protects plumbing connections, and contributes to the long-term durability of both the shower base and the surrounding floor materials.

Aligning with Plumbing and Drainage Systems

Correct alignment with the drain outlet is critical for proper water flow. Misaligned frames can result in pooling, leaks, or uneven drainage, leading to long-term structural damage. Many modern frames include height and angle adjustment options to facilitate a flush fit with the shower tray and drain system. For more complex bathroom layouts, modular frames with removable sections provide flexibility, enabling precise positioning and reducing the risk of misalignment during installation.

Proper alignment also supports maintenance and inspection. A correctly positioned frame simplifies access to plumbing components, making it easier to identify potential issues before they escalate. This approach supports a hygienic, safe, and well-maintained bathroom environment.

Prioritizing Maintenance Accessibility

Ease of maintenance is a crucial consideration during installation. Frames designed with liftable panels, removable legs, or modular sections allow cleaning and inspections without dismantling the entire system. This design ensures that bathrooms remain hygienic while reducing the risk of damage during routine upkeep. Accessible frames are especially valuable in high-use or commercial spaces, where consistent performance and cleanliness are essential.

Material Considerations for Installation

Shower Bases Support Frames come in a variety of materials, including corrosion-resistant metals, engineered composites, and durable plastics. Each material requires a suitable installation approach. Metal frames can typically accommodate standard fasteners or anchors, while lighter plastic or composite frames may rely on adhesive pads or interlocking systems. Understanding the properties of each material ensures proper support, stability, and long-term durability under repeated use.

Ensuring Safety and Load Distribution

Safety is the ultimate goal of any support frame installation. Regardless of the method, frames must distribute the load of the shower tray and water evenly across all contact points. Anti-slip feet, reinforced crossbeams, and robust brackets contribute to stability, reducing the risk of cracking or movement during everyday use. Proper installation ensures both structural integrity and confidence for users, creating a secure foundation for the entire bathroom system.

Adapting to Modern Bathroom Layouts

Modern bathrooms often include underfloor heating, integrated plumbing, and non-standard floor shapes. Flexible and modular frame designs accommodate these variations, reducing installation complexity. For renovations, adjustable components allow frames to fit different tray sizes or layouts, ensuring a professional finish even in challenging spaces. This adaptability is key to achieving both efficiency and aesthetics.

Long-Term Maintenance Practices for Support Frames

Installation alone is insufficient to guarantee longevity. Regular maintenance is essential to preserve structural integrity, hygiene, and performance over time. Factors such as humidity, cleaning agents, and daily use can affect stability and corrosion resistance. Implementing a consistent care routine extends the life of the frame and reduces future repair costs.

Routine Cleaning

Cleaning the frame regularly prevents moisture accumulation and material degradation. Using pH-neutral, non-abrasive cleaning solutions avoids damaging protective coatings. Gentle cleaning supports effective water drainage and reduces the buildup of dirt or residue.

Moisture Management

Excess humidity can accelerate corrosion or weaken structural components. Proper ventilation, such as exhaust fans or windows, minimizes prolonged exposure to moisture. For enclosed bathrooms, protective barriers or mats help prevent condensation from collecting around key areas of the frame.

Structural Inspections

Periodic checks are vital for early detection of wear or damage. Inspect legs, crossbeams, brackets, and connection points for signs of corrosion, bending, or loosening. Frames with modular or adjustable sections facilitate tightening or replacement without disassembling the entire system, preserving weight distribution and stability.

Lubrication of Moving Components

Some frames feature adjustable legs or sliding components. Light lubrication with non-corrosive oils ensures smooth operation and prevents wear. Excess lubrication should be avoided, as it may attract dust or interfere with hygiene.

Protection from Chemicals and Physical Damage

Harsh cleaning agents can degrade surfaces, while impacts from heavy objects can bend or scratch frames. Using mild cleaning solutions and careful handling during renovations maintains alignment and protects critical support areas.

Material Longevity

Frames constructed from corrosion-resistant metals, coated steel, or engineered composites provide enhanced durability. Maintaining these materials through cleaning, inspection, and careful use minimizes replacement needs and supports environmental responsibility.

Innovative Frame Designs and Industry Trends

Manufacturers are evolving support frame designs to meet modern bathroom demands. Contemporary frames prioritize flexibility, hygiene, durability, and environmental consciousness.

Modular and Adjustable Features

Frames with adjustable height, angle correction, or modular expansion simplify installation in bathrooms with irregular subfloors or non-standard tray sizes. These designs reduce labor, save time, and ensure precise alignment, particularly in renovation projects.

Integration with Smart Technologies

Some frames are being developed to work with monitoring systems. Embedded sensors can track moisture levels or detect shifts in tray alignment. Early detection helps prevent damage and reduces maintenance requirements, contributing to a safer and more efficient bathroom environment.

Advanced Materials

Durable, corrosion-resistant metals and innovative composites resist rust, moisture, and chemical damage. Eco-friendly coatings and sustainable raw materials support long-term reliability while reducing environmental impact. These materials also enhance ease of handling during installation and maintenance.

Space-Efficient Designs

Modern frames often feature compact profiles and optimized crossbeam arrangements. Slimmer designs allow more underfloor clearance, support underfloor heating, and fit in urban environments with limited space, all while maintaining robust structural support.

Hygiene and Cleanability

Smooth surfaces, minimal gaps, and easily removable components simplify cleaning routines and prevent water pooling. Hygienic design supports safer bathrooms, particularly in high-traffic areas, hotels, or commercial facilities.

Extend Longevity and Performance

Combining proper installation with ongoing maintenance ensures that Shower Bases Support Frames deliver consistent performance over time. Regular cleaning, moisture management, inspection, lubrication, and careful handling protect the frame from corrosion, misalignment, and structural stress. Selecting durable, corrosion-resistant materials and adopting thoughtful installation practices ensures a stable, safe, and hygienic bathroom environment.

By embracing flexible, modular, and innovative designs, homeowners and contractors can achieve bathrooms that are not only functional and aesthetically pleasing but also reliable and long-lasting. High-quality support frames form the foundation for performance, safety, and sustainability, demonstrating that even foundational components play a pivotal role in modern bathroom design.

-

Why Is a Shower Bases Support Frame Essential for Bathroom Stability

Nov 14, 2025

What Makes a Shower Bases Support Frame Essential for Modern Bathrooms

In modern bathroom construction, functionality and stability play a central role in ensuring long-term performance. A Shower Bases Support Frame provides the structural foundation that allows shower systems to remain secure, balanced, and durable. Beyond holding weight, it ensures that water drainage, alignment, and safety standards are properly maintained.

Building the Foundation of Stability

Every shower system requires a dependable base that distributes weight evenly across the floor. Without proper support, floors can experience uneven pressure that may lead to water leakage or surface distortion. A well-structured support frame minimizes such risks by offering balanced reinforcement and helping maintain the integrity of the surrounding installation materials.

Many modern installations combine sleek design with practicality. By integrating the frame beneath the base, contractors achieve a seamless appearance while maintaining accessibility for maintenance. The design not only contributes to visual neatness but also helps align the drainage system efficiently, promoting effective water flow during daily use.

Supporting Structural Integrity

In bathroom renovation or new construction, maintaining a stable base is key to performance over time. The support frame acts as a bridge between the shower tray and the subfloor, distributing pressure evenly. This prevents localized strain, reduces stress on joints, and keeps the base aligned. Such structural integrity is especially valuable in areas where frequent use demands dependable performance.

Moreover, the frame plays a role in sound control and vibration absorption. It minimizes creaking or shifting noises that can occur with unbalanced installations. This quiet operation enhances comfort and promotes a higher perception of build quality.

Function Contribution Practical Benefit Load Distribution Evenly spreads weight Prevents surface deformation Alignment Control Keeps tray balanced Ensures effective drainage Maintenance Access Allows easy inspection Simplifies upkeep Compatibility and Adaptation

Modern bathrooms come in diverse layouts and materials, making adaptability essential. A flexible frame can be adjusted to suit various tray dimensions, flooring types, and installation methods. This compatibility saves time during assembly and ensures a professional finish without extensive adjustments.

In commercial spaces such as hotels or residential projects, quick installation can also reduce downtime. The right frame supports this efficiency by being easy to assemble, secure, and maintain. For manufacturers and contractors alike, it represents a balance between performance and practicality.

Hygienic Design and Safety Considerations

A bathroom must not only be functional but also hygienic. Support frames designed for moisture resistance and easy cleaning help prevent mold or residue accumulation. Smooth surfaces and corrosion-resistant finishes promote cleanliness and longevity, even in humid environments.

Additionally, a stable frame enhances user safety. It minimizes movement beneath the shower tray, preventing cracks or unexpected shifts. These design features align with construction guidelines that prioritize safety without compromising appearance or accessibility.

Sustainable Construction and Material Efficiency

The growing focus on sustainable design extends to bathroom equipment. Frames made from durable and recyclable materials reduce replacement frequency and waste. Efficient use of raw materials during production contributes to an environmentally conscious construction process. Some designs also incorporate adjustable components that can be reused when bathrooms are renovated, reducing the need for entirely new installations.

Energy-efficient manufacturing methods and long-lasting materials align with global efforts to reduce carbon impact. For contractors and developers, such equipment supports environmental certification goals while maintaining functional standards.

Future-Oriented Design Concepts

As bathrooms evolve toward more modular and minimalist layouts, the role of the support frame is expanding. Future designs emphasize simplified installation and compatibility with various flooring materials, including underfloor heating systems. Manufacturers continue to innovate by creating designs that reduce installation time and allow flexible height adjustments.

Smart integration may also play a role in the near future. Some systems are being engineered to monitor moisture levels and detect leaks early. These innovations contribute to proactive maintenance, preventing costly repairs while maintaining consistent performance.

A Shower Bases Support Frame may appear as a simple structural element, yet it serves as a crucial foundation for reliability, safety, and sustainability in modern bathroom construction. Its contribution goes beyond physical support—it enables proper drainage, preserves structural balance, and enhances the overall user experience.