-

What to Check Before Selecting a Clamps Factory

Jan 30, 2026

How Buyers Evaluate a Clamps Factory Today: Practical Guidance for Safer Sourcing

In many building and industrial projects, the small items often cause the biggest headaches. Clamps are one of those deceptively simple parts: when they work, nobody notices; when they fail, everything from a pipe run to a support system can need rework. That's why more buyers are starting to evaluate the Clamps Factory behind the product with the same care they apply to critical suppliers. You want pieces that fit, finish that endures, delivery that's predictable — and a partner who understands what your jobsite actually needs.

Why the factory matters more than the catalog photo

A catalog picture can only tell you so much: hole spacing, outer diameter, maybe the coating. What photos don't show is how the clamp was formed,whether the factory tested that batch under relevant conditions. Those hidden details affect fit, fatigue life and even installation time.

Consider two scenarios:

- A contractor orders 2,000 pipe clamps for a multi-floor HVAC install. Half the deliveries fit perfectly; the other half need re-drilling because hole centers were off by a millimeter. Suddenly the crew spends hours reworking, the schedule slips, and the project accrues cost.

- A second contractor works with a factory that retains tooling logs and performs first-piece inspection. Samples are signed off before bulk production. The installed run flows with no rework.

Which outcome would you prefer? The practical difference is often the factory's production discipline — the systems behind the parts.

What to check first: a compact buyer's checklist

When you're shortlisting suppliers, focus on observable evidence that the factory runs methodically. Here's a compact checklist you can use during a phone briefing or a site visit:

- Can they provide material certificates (with batch or heat numbers) for the metal used?

- Do they perform first-piece inspections and retain the reports?

- Is there a clear workflow layout (raw material → forming → finishing → inspection → packing)?

- Can they show in-process sampling or acceptance test records?

- How do they manage coating or plating — do they measure thickness?

- What is their typical lead time and how do they handle peaks?

- Who is the technical contact for drawings and tolerances?

- Do they support pilot runs before full production?

Material and finish: more than "stainless" or "galv"

Material selection strongly influences long-term performance. But don't stop at a generic name. Ask for specifics — grade, heat number, test certificates. A few distinctions matter:

- Carbon steel may be fine for interior, dry applications. Expect cost advantage and good strength.

- Hot-dip galvanized finishes are typically used outdoors; they offer robust corrosion resistance when applied correctly. But coating quality varies with bath control and post-treatment.

- Electroplating gives a smoother finish but may be less sacrificial than hot-dip galvanizing in harsh soils.

- Stainless steel is chosen for corrosive or hygienic environments; which adds molybdenum for better resistance in marine or chemical settings.

A practical tip: for repeated orders, ask your factory to keep a slice of material as a retained sample tied to the batch number. Years later you can still reference exactly which heat went into a project.

Production processes that actually change outcomes

Some production steps have outsized effects on performance. Understanding them helps you ask the right questions.

Tooling and die condition

Tooling sets the geometry. A worn die may produce consistent parts initially, but dimensions can drift. Ask whether the factory records tooling life, performs regrind cycles, and stores tooling data.

Welding and joining practices

If a clamp includes welded joints, verify whether welding follows qualified procedures and whether welders are certified for that process. For critical applications, request non-destructive test options.

Forming and bending controls

Controlled bending avoids stress concentrations. Good shops use fixtures and jigs to repeat radii and avoid sharp bends that can create fatigue points.

Surface preparation before coating

Cleaning before coating matters. A factory that masks holes, verifies adhesion and measures coating thickness is likely to produce better corrosion performance in the field.

A small table that helps compare material and finishing options

Below is a concise comparison table you can use in buyer discussions. It highlights common choice tradeoffs and practical uses.

Material / Finish Typical Use Cases Service Traits Buyer Questions to Ask Carbon steel (plain) Indoor, dry, light structural Economical, strong but needs protection What corrosion protection is planned? Hot-dip galvanizing Outdoor, buried, external piping Thick sacrificial layer, robust in soil Provide coating thickness and bath records? Electroplated zinc Indoor/outdoor lighter exposure Smooth finish, thinner sacrificial layer Adhesion tests and salt spray data? Stainless steel 304 Food, indoor, moderate outdoor Corrosion resistance, easy cleaning Grade certs and traceability? Stainless steel 316 Marine, chemical, harsh environments Better chloride resistance Heat numbers and alloy certs? You can paste this table directly into an evaluation memo to score options side-by-side.

Why staged inspection beats final inspection only

Final inspection is necessary but not sufficient. Problems that slip into the assembly area may be expensive to correct. Better factories stage inspections:

- Incoming material check — verify grade and dimensions.

- First-piece verification — after setting up the die or tool, confirm the first parts match drawing critical dimensions.

- In-process sampling — periodically check dimensions and coatings during the run.

- Final random inspections — before packing, verify a random sample for major traits.

- Retention of samples — keep one or more sample pieces from each batch for future comparison.

Implementing these checkpoints reduces surprises. When you're onsite, ask to see first-piece reports and recent in-process logs.

Communication and documentation: the invisible quality control

A factory's documentation habits tell you as much about reliability as machinery. Good documentation shows discipline and reduces finger-pointing later.

- Drawing revision control — ensure the factory uses versioned drawings.

- Order confirmation — it should list exact specs, coatings, and acceptance criteria.

- Sample sign-off form — this protects both buyer and factory by documenting agreed acceptance.

- Inspection checklists — the factory should be able to show the checks for a sample job.

- Shipment records — traceable packing lists tied to batch numbers.

Transparent paperwork speeds dispute resolution and keeps projects on schedule.

Small pilot runs: how to do them right

A pilot run is not a "small order"; it's a controlled test. Use it to validate assumptions rather than just to receive product.

Pilot structure suggestion:

- Ask for a run that matches your production method (same forming tools, same coating, same packing).

- Require a small field trial: install 50–100 items in a real application and check fit and surface behavior over a few weeks.

- Collect install feedback: did installers need to rework parts? Was fit consistent? Any unexpected burrs or sharp edges?

- Review packing and labelling during the pilot: did parts arrive protected and correctly marked?

After a successful pilot, move to staged deliveries for the main order rather than one huge dispatch.

Practical field examples and what they teach

Real projects show how small choices ripple into major impacts. Here are three condensed examples drawn from common field experience.

Mismatched finish

A multi-storey residential job used clamps specified as "galvanized." The supplier changed the plating process mid-run due to cost, creating color and thickness differences. Installers rejected parts, delaying the schedule. Lesson: require coating thickness records and batch traceability.

Better with standardization

A hospital project worked with a factory that standardized clamps into modular kits with matching bolts and washers. Onsite assembly time dropped and inventory control simplified. Lesson: ask vendors about kit packaging and assembly compatibility.

These practical stories emphasize that the small stuff is often the most costly if it goes wrong.

Negotiating terms that protect both sides

A fair contract keeps the relationship productive. Here are practical clauses to include:

Sample approval clause: production starts only after buyer signs off samples.

- Acceptance criteria: define dimensional tolerances, coating thickness, packaging method.

- Rework/replacement terms: who pays for rejected batches and return shipping?

- Lead time and ramp clause: specify production slots and contingencies for peak demand.

- Batch traceability: require retention of material certificates and sample pieces for each shipment.

Clarity here prevents disputes and keeps the project moving when schedules are tight.

Logistics, packaging, and delivery: details that save time

Factory-to-site delivery is more than freight cost. Small decisions in packaging and labelling can save hours on site.

- Bundle by run or zone: if you're installing in phases, ask the factory to pack parts by zone and label clearly.

- Protective packing: prevent coating abrasion with separators and soft packing material.

- Consistent labelling: barcodes or clear part numbers reduce receiving time and misplacement.

- Palletization for efficiency: pallets that match your site handling equipment speed unloading.

When you plan logistics with the factory, you reduce handling time and minimize damage in transit.

Building a long-term relationship: what to expect

If you plan multiple projects or long maintenance cycles, a steady supplier relationship pays off. Over time a factory learns your preferences, tooling needs, and packaging style. That reduces setup time and improves predictability.

Practical steps to build the relationship:

- Run small pilot orders across initial projects.

- Keep a re-order schedule and communicate forecasted volumes.

- Offer feedback after installation to help the factory refine processes.

- Consider annual or semi-annual QA reviews to align standards.

A good supplier partnership behaves like a trained subcontractor — familiar, predictable, and easy to work with.

Quick action checklist for a procurement meeting

Use this checklist when you have a short window to evaluate a new supplier.

- Request material certificates from the last three batches.

- Ask for a first-piece report and an in-process sampling log.

- Request a 10-minute video showing the die setup and forming operation.

- Confirm coating method and ask for thickness data (µm).

- Agree on sample sign-off and pilot run terms.

- Clarify rework and replacement terms in writing.

- Ask about peak capacity handling and lead time under high demand.

This gives you a realistic snapshot without a full factory audit.

Emerging trends to watch

- Digital traceability: dashboards tied to production status and inspection logs will become more common. Ask whether suppliers offer production status updates.

- Sustainability: some buyers will expect information about material sourcing and waste management. It's increasingly relevant for public tenders.

- Modular kits: pre-kitted clamp assemblies reduce onsite handling and errors. Consider whether a factory can deliver kit options.

These trends don't change fundamentals but influence what "good" looks like in sourcing.

Small parts, big impact

Clamps are small, but they hold systems together — literally. Choosing the right Clamps Factory influences installation speed, system reliability, and long-term maintenance. Focus your evaluation on the production systems behind the parts: material control, tooling discipline, staged inspection, and clear documentation. Combine a practical pilot with a clear contract and packaging plan, and you'll reduce field rework and improve schedule performance.

-

Cold Corridor Support Brackets for HVAC Systems

Jan 28, 2026

In HVAC installations, cold corridor or cold zone areas require reliable support solutions for pipes, radiators, and related components. Cold corridor support brackets are designed to provide structural stability while accommodating temperature changes and long-term operation.

Unlike standard mounting hardware, HVAC cold corridor support brackets must offer higher strength and precise positioning. Improper support may lead to misalignment, noise, or stress on connected systems.

JINYI manufactures cold corridor support brackets and related HVAC installation hardware for commercial and industrial projects. These brackets are designed to support heating and piping systems in demanding environments, with options for different mounting methods and load requirements.

By supplying standardized models as well as customized solutions, JINYI supports HVAC contractors, system integrators, and equipment manufacturers seeking reliable support hardware. Well-designed cold corridor support brackets contribute to safer installations and more durable HVAC systems.Discover more about our products and global supply solutions at https://www.yh-jinyi.com

-

Why Do Radiator Mounting Brackets Matter in Equipment Design

Jan 26, 2026

Radiator Mounting Bracket plays a quiet but essential role in keeping equipment running day after day. People rarely notice it—until something goes wrong. At that moment the bracket is suddenly very visible: bent, corroded, loose, or otherwise failing. The good news is one of these headaches are avoidable if buyers and engineers pay a little attention at the design and procurement stage.

Vibration is the usual culprit behind many late-life problems. Even modest vibration, repeated thousands of times, will fatigue joints, wear fasteners, and loosen hoses. A bracket that is too rigid and bolted directly to a vibrating frame will transfer stress. A bracket that is too flexible will let components move out of alignment. The practical solutions balance stiffness with local damping—simple rubber isolators or engineered bushings can absorb energy and greatly extend component life. Have you ever compared two machines side by side and wondered why one seems quieter? Often the mounting strategy makes the difference.

Fit and alignment matter more than many expect. A radiator mounted a few millimeters off-center may cause the fan and cowling to rub, or force hoses into sharp bends that shorten their lifespan. Small misalignment also impairs airflow, which can raise operating temperature by a few degrees—enough to accelerate wear or trigger protective shutoffs. For repeatable production and reliable field service, favor mounting designs that include slotted holes or adjustable interfaces: they let technicians fine-tune position quickly during assembly or maintenance.

Think about the environment. Corrosion, salt spray, chemical splash, and constant moisture all shorten the life of ordinary steel. In coastal installations or outdoor equipment, corrosion-resistant materials or protective coatings pay off. Stainless steel brackets, zinc-plated steel with appropriate passivation, or polymer-coated alternatives each have tradeoffs in strength, cost, and longevity. The right choice depends on whether weight savings, cost, or corrosion resistance is the priority. Don't let material choice be an afterthought—describe the site conditions clearly to your supplier.

Maintenance access is another practical point often missed in early design. A bracket that tucks the radiator tightly into the frame may look neat, but it can complicate oil changes, hose inspections, and fan servicing. If technicians need to spend extra time disassembling surrounding components just to reach a few bolts, maintenance intervals will stretch out or be skipped—both bad outcomes. Design for the workers who service the equipment: removable panels, quick-release fasteners, and service clearances mean faster, safer field work and fewer chances for small issues to grow into big ones.

Customization makes sense when off-the-shelf parts won't fit. Retrofitting newer radiators into older frames, tight engine bays, or bespoke mobile platforms often demands tailored brackets. Custom brackets can incorporate integrated vibration mounts, added reinforcement where loads concentrate, or special flanges for nonstandard bolt patterns. Work with a supplier who asks detailed questions about your application: load cases, expected vibration spectra, and service routines. A short design dialogue upfront can avoid costly rework later.

Material selection also affects thermal behavior. Radiators need to dissipate heat without introducing thermal stresses to the support structure. Bolted steel supports that expand at one rate while the radiator body expands at another can create stress concentrations. In high-temperature cycles, consider combinations of materials or flexible joints that accommodate differential expansion. Simple design touches—like locating bolt holes to allow slight movement—prevent fatigue cracking over thousands of thermal cycles.

When should you replace a mounting bracket? Visible deformation, creeping fasteners, cracking around holes, or worsening vibration and noise are clear signs. But don't wait for visible failure. If inspection reveals progressive looseness, paint flaking near joints, or minor cracks appearing at weld toes, schedule replacement during the next service window. Proactive replacement during regular maintenance keeps unscheduled downtime at bay and protects connected parts like hoses and sensors.

Installation technique matters nearly as much as the design itself. Proper torque values, correct use of washers and lock-nuts, and attention to corrosion protection at fastener interfaces all extend bracket life. During installation, use a calibrated torque wrench and follow a cross-pattern tightening sequence where appropriate. Avoid over-tightening: it can distort the bracket or strip threads. A short checklist for installers—torque specs, alignment tolerances, and inspection points—reduces human error on the shop floor and in the field.

For production lines, consider repeatability. Brackets that allow a technician to position a radiator quickly and consistently help reduce cycle time and lower rework. Locating features, simple jigging, or captive fasteners streamline assembly and reduce the chance of misinstallation. When you scale from prototype to production, those small minutes saved per unit add up to meaningful throughput gains.

Noise and operator comfort are important in many applications. Unwanted rattles and buzzing distract operators and can mask other warning sounds. A thoughtful mounting approach that isolates vibration not only improves equipment longevity but also enhances user experience. In installations where noise limits are enforced—urban equipment, indoor facilities, or hospitality settings—planning vibration reduction into the mounting design avoids costly retrofits later.

Supply chain reliability also deserves attention. For large projects or replacement programs, you need a source that can deliver consistent parts with predictable times. Choose suppliers who provide clear documentation—material certificates, dimensional drawings, and batch traceability—so you can audit and replicate installations across fleets. Standardized part numbers and packaging help procurement teams manage inventory and reduce confusion during high-pressure maintenance windows.

A few practical tips to help buyers choose the right bracket:

- Share full context with suppliers: not just radiator dimensions, but expected loads, vibration conditions, exposure to chemicals or salt, service access needs, and projected service life.

- Prioritize brackets with adjustable or slotted mounting features for fine tuning during assembly.

- Insist on corrosion protection appropriate to the environment—this often saves more over a product lifetime than small initial savings on raw materials.

- Verify that the supplier supports testing or provides references from similar applications. Real-world feedback is invaluable.

- Include maintenance considerations in the design spec so field teams can perform routine checks without dismantling adjacent systems.

Use cases show how varied requirements can be. In construction equipment, brackets often need extra reinforcement and vibration damping because machines work on rough terrain. In data center chillers, the emphasis is on precise alignment and quiet operation, while in marine applications corrosion resistance and secure fastenings take precedence. A single bracket type seldom suits all these needs, which is precisely why good vendor collaboration matters.

Remember that radiator mounting brackets are small components that can have outsized consequences. A failure that seems minor—like a loose bolt—can cause cascading problems: hose chafing, coolant leaks, fan damage, and ultimately more extended downtime. Investing a little effort up front to choose a well-designed, well-installed bracket repays itself many times during service life.

-

Why Do Shower Tray Feet Matter for Bathroom Stability

Jan 23, 2026

How Shower Tray Feet Make Installations Last: A Practical, On-the-Ground Guide

If you've ever stepped into a shower and felt a hollow thunk underfoot, or seen a tray crack months after installation, you know the finish can hide real problems. The visible parts — tiles, tray, glass — get all the attention. But the bits underneath, especially support feet, decide whether a job stays trouble-free. Choose the right system, install it carefully, and the whole bathroom behaves itself for years. Get this wrong and you'll be back on site sooner than you want.

What shower tray feet actually do (more than you might think)

At a basic level, shower tray feet support the tray. Seems obvious. But support involves a few distinct jobs:

- Leveling — compensating for an uneven floor so the tray sits true with the proper fall to the drain.

- Load distribution — spreading weight so the tray doesn't flex or stress at isolated points.

- Vibration control — reducing movement that leads to creaks, seal fatigue, and loosening joints.

- Corrosion resistance — standing up to moisture, cleaning agents, and humidity over time.

- Serviceability — being accessible and predictable if the tray ever needs adjustment or removal.

Put a tray directly onto an irregular floor and you create stress points. Over time those stress points produce hairline cracks or seal failures. Adjustable feet let you dial the tray into a stable, evenly supported position without rebuilding the entire subfloor.

Common subfloor realities installers face

Understanding the subfloor you're working with changes how you pick support components. Here are typical situations and why they matter:

- Old buildings — joists, uneven screeds, settling. Expect variations and small dips that need corrective adjustment at each support point.

- New builds — even concrete slabs aren't perfectly level after screeding or curing. There may be areas higher or lower than expected.

Retrofits and refurbishments — tile heights, underfloor heating, or layers of existing material can create limited clearances. You need low-profile feet or a system that works with the build-up.

Lightweight subfloors — timber or OSB sheets can flex more under point loads; you need more support points or larger load-bearing pads.

The realistic answer is rarely "rip it out and pour new concrete." Labour and programme constraints make adjustable supports the practical fix on many projects.

Materials and design: what to pick for durability

Feet are made in different materials and configurations. Pick according to use and environment.

Common materials

Engineered plastics / reinforced polymers

- Pros: corrosion resistant, light, cost-effective.

- Cons: some grades compress under load over many years — choose high-grade engineering plastics.

Stainless steel

- Pros: strong, durable, high load capacity.

- Cons: must be properly finished (passivation/coating) to resist long-term corrosion in wet rooms.

Hybrid/composite (metal core with plastic outer)

- Pros: good compromise — metal strength, plastic corrosion protection.

- Cons: slightly higher cost, but often the best balance.

Design considerations

Adjustment range — how many millimetres of height you can correct. Small jobs need modest range; poor floors need more.

Footpad size — larger pads spread load, reduce local compression, and work better on thin subfloors.

Anti-rotation / locking mechanism — once adjusted, feet should lock solidly so they don't drift under load.

Access for tools — installer-friendly designs cut time and risk (you don't want to wrestle with awkward keys in tight spaces).

Compatibility with adhesives/bed systems — some trays are bonded; others sit on feet only; check the tray spec.

Pre-install checks: what to do before the tray arrives

Good installation starts with measurement.

- Measure floor flatness: a simple straightedge across several axes tells you a lot. Mark high and low spots.

- Check clearances: underfloor heating, pipework, or structural beams may limit adjustment depth.

Confirm drain and waste location: ensure the support layout doesn't obstruct the trap or waste assembly.

Plan access: can you adjust feet after tiling? If not, set them precisely before finishing.

Getting these checks right avoids improvisation when the tray shows up and the client is waiting.

Hands-on installation sequence (step-by-step)

Follow a checklist, not guesswork. Below is an installer's sequence that tends to work on most jobs.

Dry fit the tray on the floor to see how it sits. Don't apply adhesive yet.

Sketch support locations based on tray ribs and drain position. Mark them on the floor.

Set initial foot heights — approximate so the tray can be placed and nudged into position.

Place the tray carefully onto the feet. Use shims if needed for temporary support.

Adjust feet methodically:

- Start at one corner, then the opposite, then centre points.

- Tighten gradually to bring the tray level; don't crank one foot down and leave others high.

- Check level and fall: measure the fall to the waste. There should be a continuous drop where specified (typically a small gradient).

Apply final fixings (if the system requires mechanical fixing) or proceed with adhesive bed as per tray manufacturer.

Test: apply weight across various points on the tray (step tests) and re-check level/fall and any movement.

Seal around the waste and edges as required but avoid over-constraining the tray movement — some systems need slight movement to relieve stress, others need full bonding; follow the tray guidance.

Common installation mistake: tightening feet before the tray is properly aligned. This locks in an out-of-level support and often causes problems.

Avoid these rookie mistakes

These errors repeat across many sites. Avoid them:

- Using too few support points for a large tray — leads to sagging.

- Relying on adhesive alone on uneven floors — adhesive can bridge gaps short term but will fail under movement.

- Over-torquing metal feet without locking features — parts can strip or create concentrated stress.

- Not allowing for thermal movement — bathroom temperatures vary; rigidly fixed systems can cause cracking.

- Ignoring manufacturer instructions — tray manufacturers often specify support patterns and bonding methods. Follow them.

Drainage and fall: getting the water moving

A good support system helps maintain the small fall needed for effective drainage. If the tray is slightly out of plane or flexes, water can sit and create hygiene and leak risks.

- Target fall: often between 1–3 degrees depending on product spec.

- Uniformity: avoid local high spots near the drain that trap water.

- Drain compatibility: ensure the foot layout doesn't obstruct trap seals or access for cleaning.

If you must route around existing drainage, plan the support layout first. Never sacrifice fall for convenience.

Maintenance, inspection and long-term checks

A well-installed tray will need little intervention. Still, a periodic check is sensible:

- Seasonal visual check: step on the tray in several places — listen for creaks or movement.

- Inspect seals around the waste annually. Early signs of movement show up here first.

- Check fixings if accessible: any loosening can be tightened before stress accumulates.

- Watch for corrosion on older metal feet and replace if required.

In high use or rental properties, incorporate these checks into routine maintenance schedules.

Special situations and solutions

Timber floors or suspended decks

Use larger footpads and more support points. Timber flexes; spread the load. Consider tying the supports into joists where feasible.

Underfloor heating

Keep electrical components clear. Some adhesive beds may not be suitable; follow both tray and heating manufacturer instructions. Avoid over-insulation under feet — you need solid contact.

Wet rooms and flush installations

These require robust waterproofing and often closer support spacing. The waterproof membrane and support system must be compatible.

Retrofit over tiles

If you're fitting a new tray over old tiling, assess tile adhesion first. Floating tiles can move and undermine support; sometimes a localized screed or spot re-bedding reduces risk.

Product selection checklist (quick practical list)

When choosing a set of feet, ask these questions:

- Does the adjustment range match the unevenness you measured?

- Are the pads large enough for your subfloor type?

- Is the material suited to the environment (stainless vs polymer)?

- Is there a clear locking mechanism to prevent creep?

- Do the manufacturer's tray specs confirm this layout?

- Is there support documentation for installers?

- What is the expected lifespan or warranty of the system?

Buying cheap can cost more in remedial visits. Small investment in the right components often saves time and reputation.

Case studies from the field (real patterns, no names)

Here are three short, anonymised examples that illustrate how feet choice matters.

Case A — 12 unit apartment block

Problem: Several trays developed slow leaks at the third year mark.

Cause: Installer used adhesive-only method on slightly uneven screed. Over time, micro-movements opened grout joints at the waste.

Fix: Retro-fit adjustable feet and re-seat trays with manufacturer-specified bonding. Result: leak incidents dropped to none in following 3 years.

Case B — Hotel refurbishment

Problem: Guests complained of hollow or creaky sensation underfoot in a cluster of rooms.

Cause: Installer used too few support points on long, narrow trays.

Fix: Added intermediate supports matching tray ribs; re-leveled trays. Result: clients noticed the improved feel immediately; maintenance calls dropped.

Case C — Old building conversion

Problem: Tile cracking around showers in bathrooms over timber floors.

Cause: Point loads from existing small feet caused localized stress.

Fix: Swapped to larger pad composite feet and tied supports to joists. Result: cracking stopped and inspections showed reduced movement.

These examples are common and useful when planning projects: think ahead or budget for retrofit support.

Installer habits that save time (and headaches)

A few habits can make quality consistent across teams:

Two-person dry fitting: one holds, one adjusts; saves damage and speeds up levelling.

Label adjustments: mark final heights on a plan — makes rework faster.

Keep a reference tool: a short spirit level and feeler gauge for quick checks.

Document as you go: photo the layout before final bedding — handy if client complains later.

Use shims sparingly: they're fine for temporary alignment, but don't be tempted to rely on them as a permanent fix.

Good habits make margin for error smaller.

What installers should tell clients (setting expectations)

Clients don't usually care about feet — until something goes wrong. A quick, clear explanation before handover avoids trouble:

Explain that the tray sits on adjustable supports to compensate for floor irregularities.

Point out the maintenance check schedule (annual visual).

Note what the warranty covers and what it doesn't (movement from misuse vs manufacturing fault).

If you had to use more remediation than planned (e.g., additional supports), mention it in the handover notes.

Clear communication reduces call-backs.

Final checklist before you walk away from the job

Before you close up the bathroom, run this quick checklist:

- Tray is level and has the correct fall to the waste.

- No point loads or visible gaps beneath the tray.

- All adjustment points are locked and, if required, sealed to prevent moisture ingress.

- Waste assembly is accessible or removable without tearing out the tray.

- Client has been shown where to inspect and sign-off.

You photographed the final setup.

If all that's green, you've done the practical bit right.

Supporting a shower tray properly is not glamorous. Nobody posts about feet on social media. But these components guard against the kinds of failures that lead to repeat visits, bad reviews, and wasted time. Treat support design as part of the finish. Get the layout right. Choose materials with the job in mind. Adjust carefully. And document so everyone knows what was done.

Do that and the finished bathroom won't just look good — it will work quietly and reliably for a long time.

-

Why Choose a Shower Tray Frame Instead of Cement Installation?

Jan 21, 2026

When it comes to installing a shower tray, many homeowners and contractors still rely on traditional cement installation. However, more and more professionals are switching to shower tray frames — a smarter, cleaner, and more adjustable solution for modern bathrooms.

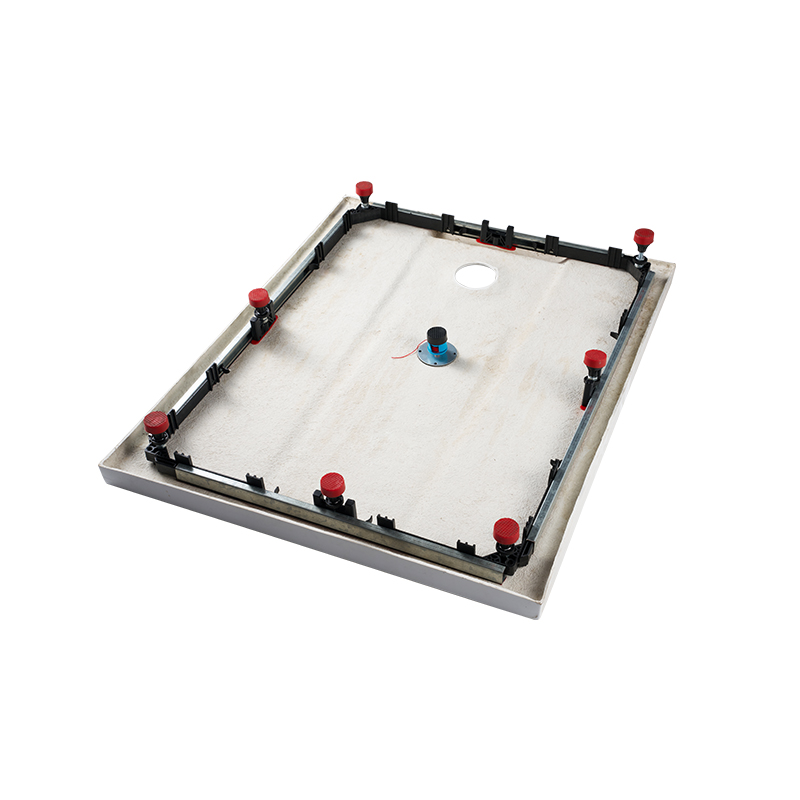

What Is a Shower Tray Frame?

A shower tray frame (also called a shower base support frame) is a modular metal structure designed to hold and level a shower tray securely. Compared with cement or foam installations, it offers flexibility, faster installation, and long-term stability.

Why Use a Shower Tray Frame?

- Easy Installation & Adjustment

No messy cement mixing. The height-adjustable legs allow installers to achieve a perfect level in minutes — ideal for uneven floors or renovation projects.

- Maintenance & Accessibility

Frames make it easier to access the plumbing system beneath the tray for inspection or repair — something impossible once cement hardens.

- Lightweight but Strong

Made of stainless steel or galvanized steel, shower tray frames provide solid support while remaining lightweight and corrosion-resistant.

- Clean, Modern & Eco-Friendly

No dust, no waste, and fully recyclable materials — meeting modern environmental standards for sustainable construction.

About JINYI – Your Reliable Shower Tray Frame Manufacturer

Yuhuan Jinyi Hardware Co., Ltd. is a professional manufacturer of shower tray frames and support systems, with over 30 years of export experience serving European markets.

Our shower tray frames are widely used with brands across the UK, Germany, and Northern Europe — compatible with popular shower tray models from leading bathroom manufacturers.

Why Choose JINYI?

- CE Certified products ensuring compliance with EU safety standards

- ISO9227 NSS tested for anti-corrosion performance、

- OEM & ODM support – customized sizes, structure, and packaging

- Flexible MOQ to support both distributors and brand owners

- 30 years of global export experience with professional logistics and documentation support

OEM / ODM Cooperation

Whether you are a shower tray manufacturer, bathroom brand, or distributor, JINYI provides one-stop OEM/ODM solutions.

From frame design and mold development to sample testing and certification, our team ensures that every project runs smoothly and efficiently.

Contact Us

Looking for a reliable shower tray frame supplier in China?

Let JINYI help you simplify installation, improve efficiency, and enhance your product competitiveness.

Visit: https://www.yh-jinyi.com

Email: [email protected]

-

Why Does a Bathtub Mounting Frame Matter

Jan 19, 2026

How Can a Bathtub Mounting Frame Improve Bathroom Installation Safety

A bathtub mounting frame does a simple job, but it changes how an installation behaves over time. Put a tub on a wobbly base and problems show up later: leaking joints, cracked tiles, awkward plumbing. Put it on a proper frame and those headaches drop a lot.

Here's a practical look at what a mounting frame actually does on site, and why installers are choosing them more often.

Hold the tub steady from day one

Floors are rarely perfect. Even new builds have small dips or slopes. A mounting frame lets you set the tub level without shoveling in a bunch of mortar or hacking out the subfloor.

That matters because a level tub spreads weight evenly. No one corner does all the work. Sealants stay put. Wall finishes aren't pulled when someone climbs in and out. Simple, but effective.

Protect the plumbing

Tubs connect to drains and overflow pipes. If the tub shifts, those joins can be strained. A mounting frame keeps the tub where it should be, so pipes stay aligned and less likely to leak.

On renovation jobs especially, the frame gives you control. You can set the tub at the right height and keep the drain slope correct without guesswork. That saves time and avoids awkward fixes later.

Cut down hidden moisture risks

Water under fixtures is a slow killer — it ruins adhesives and makes timber rot. Frames often lift the tub slightly, which creates a small airflow gap underneath. It's not flashy, but that little breath of air reduces trapped damp and slows down hidden damage.

Over years, that makes a difference to the subfloor and the finishes above it.

Make maintenance simpler

When drains block or a gasket needs attention, removing tiles to reach the problem is a pain. A frame-based installation can make minor service work easier — sometimes you only need to move a trim or a panel rather than demolish the floor.

Less disruption for occupants, less fuss for trades. That's worth planning for.

Fit a range of site conditions

Whether you're working on timber joists, concrete slabs, or an older uneven floor, mounting frames adapt. Adjustable feet and brackets let you fine-tune the position on site. That flexibility is a big advantage in refurbishments where nothing lines up quite as the drawings promised.

It's also handy when fitting tubs next to wet-room thresholds, under heated floors, or alongside linear drains.

Improve perceived quality

A tub that wobbles or sounds hollow gives a cheap feel to an otherwise tidy bathroom. Proper support reduces flex and vibration. The tub feels solid underfoot. That quiet confidence matters to homeowners and to property managers in rental units.

Small comfort, visible effect.

Practical tips for installers

- Check the underside of the tub before you pick a frame — know where it needs support.

- Set the tub level first, then lock the frame. Don't rely on sealant to hold alignment.

- Use corrosion-resistant fixings in wet areas.

- Plan a small service access where possible — it saves time later.

- Take photos of final settings for future servicing notes.

These steps cost little time on site and save larger headaches later.

When a frame is the smart call

If you're working on a renovation, handling an awkward subfloor, or installing in a multi-use building, a mounting frame is worth considering. Even on new builds, the control and serviceability it brings make life easier for installers and occupants.

It won't fix poor planning, but it does reduce the common failures that show up after handover.

A mounting frame is a small item with a practical payoff. It keeps the tub stable, protects plumbing, improves moisture behaviour, and makes future work less destructive. Treat it as part of the build's structure rather than an optional add-on — that one choice makes the whole installation more reliable and less trouble to live with.

What Are the Key Factors to Choose the Right Bathtub Mounting Frame

Picking the right mounting frame matters. It's one of those small choices that shows up later if it's done wrong. A good frame keeps a tub steady, protects plumbing, and makes future work less disruptive. Below are practical points to check on site.

Check the site first

- Look at the floor and the room before you pick a frame.

- Is the subfloor concrete, timber, or raised access? Each behaves differently under load.

- How flat is the surface? Small dips are normal; big slopes need attention.

- Where is the drain and how will you get the fall right?

- Will there be underfloor heating, insulation, or a linear drain to work around?

Make adjustability a priority

- Few floors are perfect. Choose a frame you can tweak on site.

- Smooth, small increments are better than coarse steps.

- The locking should hold firmly once set. A slipping lock means movement later.

- Pick a system that's easy to access while you're installing it.

Match the frame to the tub shape

- Look under the tub before you buy a frame.

- Flat bases like broad, distributed supports.

- Ribs or molded feet need targeted contact points.

- If the tub maker recommends a support pattern, use it.

Think about moisture and materials

Bathrooms are damp. Choose parts that cope with that.

- Metal: corrosion-resistant or coated parts work better in wet rooms.

- Plastics: pick types that stay tough after repeated wet-dry cycles.

- Timber: if you must use it, keep it treated and away from direct moisture.

Don't forget noise and feel

A tray that flexes often sounds hollow. It also feels less secure.

Use multiple supports to reduce movement.

Add thin dampening where timber joists might transmit sound.

Tighten locking points so small shifts don't happen underfoot.

Plan for service access

- Pipes need attention at some point. Think about that now.

- Can you add a small service panel or hatch? It pays off later.

- If a hatch isn't possible, make sure plumbing runs are reachable from elsewhere.

Document where access points are for the owner.

Match strength to use

- Not every bath sees the same traffic.

- Home ensuite: light-duty support often suffices.

- Rental, hotel or public shower: pick more robust systems and extra support points.

- Adding seating or grab rails changes loads — account for that.

Coordinate with other systems

Don't install the frame in isolation.

- Ensure clearance for underfloor heating and insulation.

- Confirm drain interfaces for point or linear drains.

- Check how the frame affects tile thresholds and trims.

- Choose a supplier who helps on site

A good vendor does more than ship boxes.

Ask for clear install guides.

- Check for spare parts availability.

- See if they can share job references.

- Quick on-site checklist

Before you fix the frame, tick these:

- Subfloor type noted.

- Tray underside inspected.

- Drain alignment confirmed.

- Frame adjustment tested and locked.

Access point planned.

Corrosion resistance verified.

Photos of final settings taken.

A bathtub mounting frame is a small item that does heavy work. Choose it based on the site, the tub shape, and how the room will be used. Prioritise adjustability, moisture resistance, and future access. That way the installation stays quieter, simpler to maintain, and less likely to cause problems down the line.

Why Do Contractors Recommend Adjustable Bathtub Mounting Frames

Contractors talk about these frames because they solve everyday site headaches. A tub looks fine at first. Weeks or months later, small movements show up as cracks, leaks, or noisy floors. A frame that adjusts on site removes a lot of that guesswork.

Fix the floor, fast

Few floors are perfect. Timber joists sag a bit. Concrete can slope. With a frame you can tweak the tub's height at several points. No waiting for mortar to cure. No bulky packing. You set it, check the level, then lock it down. That's quicker and cleaner.

Keep the plumbing steady

Tubs hide drains and overflow pipes. If the base shifts, those joins take strain. Frames spread the load so pipes stay lined up. That means fewer leaks and less fiddly patchwork later. On a retrofit job, that stability is worth its weight in saved hours.

Make future repairs easier

Plumbing needs work sometimes. Gaskets wear, drains clog. A tub set on a rigid bedding often means breaking tiles to get in. With a framed base, you can plan small access points or move the tub a little without wrecking the finishes. Less demolition. Less mess.

Cut noise and feel solid underfoot

Hollow-sounding tubs are common in apartment blocks. They make the installation feel cheap. Firm supports reduce vibration and flex. Steps sound quieter. The tub feels firmer. It's a small comfort that owners notice right away.

Fit modern systems without hassle

Underfloor heating, linear drains, insulation layers—these add complexity. Frames give you clearance and fine adjustment so the tub works with other systems. You can align tiles and thresholds cleanly without compromising structure.

Save time on site

Mortar beds take time and can go wrong. A tweakable frame speeds the job. Teams waste less time reworking levels or chasing leaks. That efficiency keeps projects moving and reduces costly callbacks.

Practical checklist for installers

- Inspect the tub underside before picking the frame.

- Dry-fit the frame and confirm drain alignment.

- Adjust each support until level, then lock.

- Use corrosion-resistant fixings in wet areas.

- Plan a small access panel if possible.

- Photograph final settings for future reference.

These small steps cut future headaches.

When a framed solution matters most

Renovations, uneven subfloors, high-traffic bathrooms, and jobs with underfloor systems—these are the cases where a frame pays off. On simple, straight new builds you can still gain from the control and serviceability it brings.

A mounting frame won't replace good planning, but it makes the installation forgiving. It keeps the tub steady, protects plumbing, eases later repairs, and gives a firmer feel underfoot. For many contractors, that combination is why they specify framed supports as a standard part of the job.

When Should Homeowners Inspect or Replace a Bathtub Mounting Frame

Most people forget about the bits under the tub. That's fine — until the tub starts to rock, grout cracks, or a slow leak shows up. A brief inspection at the right time stops small problems from turning into big repairs. Here's a straightforward, no-fluff guide you can use.

Why check the support under the tub

A mounting frame spreads weight and keeps the tub steady. Without it, a corner can take too much load. Over months that shows up as cracked grout, pulled seals, or loose tiles. A simple frame gives you control when installing and makes later fixes easier.

Think of it as insurance: small cost, but it saves a lot of hassle later.

Quick signs that deserve a look now

You don't need special tools to notice trouble. Walk through the room and check for:

- A wobble near the tub edge when you press down.

- Tiny gaps or cracks in the grout around the tray.

- New damp smells or staining near the base.

- Soft or springy spots on the floor beside the tub.

- Silicone or sealant that pulls away after light use.

If any of these show up, plan a closer inspection. Don't ignore one sign and hope the rest stays fine.

Best times to open things up

There are moments when inspecting or swapping a frame is much easier:

- During a full bathroom renovation — the floor is open anyway.

- After a leak or water damage repair — you already have access.

- When changing the bath to a walk-in shower — geometry changes.

- Before laying new floor finishes — avoid blocking access later.

If the room's use increases — a guest bath becoming a daily shower.

Pick one of those windows and deal with the frame while the place is already open.

How often to inspect

No hard rule, but a handy rhythm is:

- Quick visual check once a year.

- Do a hands-on press test every time the room is emptied for cleaning.

- Full inspection when you renovate or after any leak.

High-traffic bathrooms need checks more often. If the space gets heavy daily use, shorten the rhythm.

What to look for — a short checklist

CheckWhat to do

- Edge stabilityPress each rim and corner — feel for movement

- Grout & tilesLook for cracks, gaps or fresh stains

- Floor feelWalk around — any spring or bounce?

- SealsInspect silicone and joints for gaps

- Visible hardwareLook for rust or brittle plastic parts

- AccessIs there a hatch or removable panel?

Take photos of anything odd. A picture helps a tradesperson diagnose the issue later.

Materials age differently — keep that in mind

Frames come in metal, plastics or composite mixes. Each shows wear in its own way:

- Metal: check for rust or pitting, especially in damp spots.

- Plastic: look for cracks or brittleness from long wet-dry cycles.

- Composite: check the joins and screws for movement.

If adjustable parts won't lock or move smoothly, that's a red flag.

Maintenance that actually helps

- A little effort now keeps the job tidy later.

- Keep a small access panel near the tub if you can. It saves breaking tiles.

- Tighten lock nuts after a few months of use. Small slips can creep over time.

- Note any adjustment settings — a quick photo with a ruler saves time later.

Use corrosion-resistant fixings in wet rooms.

These moves take minutes but prevent messy work later on.

When to replace the frame

Replace the frame when:

- Movement persists after tightening and adjustment.

- Corrosion or material fatigue is visible.

- Plumbing is misaligned and can't be corrected with adjustments.

- You already have access during a renovation — do it then.

Replacing is cheaper and neater when the floor is already open. Don't wait for a leak to force the issue.

A few realistic scenarios

- Apartment renovation: owner swapped the tub and left a small hatch for service. No tiles were damaged later when the drain needed attention.

- Old house: timber joists had settled. Installer used an adjustable frame and removed the need for heavy mortar packing.

- Rental property: frequent turns increased wear. A switch to a sturdier, adjustable system cut callbacks.

Real jobs like these show why a bit of planning pays off.

Simple advice for homeowners

Inspect casually every year. It's quick.

If you notice wobble or damp, act sooner rather than later.

Plan to check the frame when doing other bathroom work.

Keep a photo record of the frame and any settings.

Ask for corrosion-resistant parts in wet areas.

A small habit prevents big costs.

Frames are small parts that do a lot of heavy lifting. They keep tubs steady, plumbing aligned, and repairs easier down the line. A short check now saves time, money, and mess later. If you've got a renovation coming up, include the frame in the plan — it's the practical choice.

-

Why Are Shower Tray Support Legs So Important

Jan 16, 2026

What Makes Shower Tray Support Legs Essential for Modern Bathroom Installations

People rarely notice what sits under a shower tray — until something goes wrong. Yet those unseen components do a lot of work: they keep the tray level, protect piping, allow airflow under the base, and help the whole installation last longer. In practical terms, adjustable support legs are one of the simplest ways to improve durability and reduce headaches later on.

This article looks at why these small parts matter. I'll cover how they help with stability, water management, installation flexibility, and future maintenance — with examples that contractors and homeowners will recognize.

Why a solid foundation matters

Imagine a tray sitting on an uneven floor. At first, it might look fine. Over time, however, movement adds up. Grout cracks, seals loosen, and tiles can separate. Those are costly repairs and they're avoidable.

Support legs let installers level the tray precisely. Instead of hoping the bedding mortar sets flat, the legs give multiple adjustable points under the base. That spreads weight evenly and prevents single-point stress. The result: a tray that stays put and a finish that stays tidy.

Short version: a stable base saves money and trouble.

Fine-tuning on the job

No two jobs are identical. Subfloors vary. Pipe runs differ. Sometimes the drainage slope needs minor tweaks. Mortar beds can work, but they take time and they're not forgiving.

Leg systems let an installer tweak height and angle on-site, fast. That makes it easier to match drains, route pipes, and keep the finished level exactly where it should be. It also shortens the installation time — one reason many crews prefer leg systems on tight schedules.

Practical point: this flexibility reduces rework and keeps projects on track.

Moisture control you can't see but can feel later

Bathrooms are wet places. Trapped moisture under a tray is a slow, hidden problem. It can soften adhesives, encourage mold, and damage subfloors over months and years.

Raised support with a small air gap improves airflow beneath the tray. That ventilation helps moisture evaporate rather than staying trapped. It's not a dramatic fix you'll notice today, but it prevents a lot of small failures down the road. In other words, it's cheap insurance for the build.

Handling repeated use without complaint

Homes, hotels, gyms — some bathrooms see a lot of traffic. Repeated stepping, shifting, and weight cycles add mechanical stress. If the tray sits on a single unsupported area, that stress concentrates and material fatigue follows.

Distributed support spreads those loads across multiple points. The tray flexes less, seals stay intact longer, and finishes keep looking good. In places with heavy use, this is the difference between routine upkeep and constant repairs.

Easier access for maintenance

Here's a fact some clients don't think about until it's necessary: plumbing needs attention. When drains clog or a pipe joint needs checking, a fully mortared tray can make access awkward and destructive.

A raised tray with discreet service access makes inspection and minor repairs simpler. Technicians don't have to demolish finishes; they can reach service points more easily. Less disruption for occupants, lower repair bills, and fewer emergency calls — all practical wins.

Match design with function

Design trends often favour slim trays and flush floors. Achieving that look while keeping the build reliable is a technical challenge. Support legs let designers keep the slim aesthetic while still leaving room for plumbing, drainage tolerances, and necessary clearance.

They also allow integration with underfloor heating, insulation layers, or linear drains without compromising structural support. In short: good engineering underpins good design.

Reduce waste and support sustainability

A fully mortared base uses a lot of material and can be wasteful if onsite adjustments are needed. Adjustable leg systems reduce the need for excessive bedding material and lower the chance of remakes. Over time that means fewer resources used, less demolition waste, and fewer replaced components.

When projects aim for longer service life and fewer renovations, that kind of efficiency matters.

Quieter, more comfortable showers

Hollow or poorly supported bases can sound hollow underfoot. In multi-storey buildings, that noise carries and becomes a nuisance to people below.

Leg support reduces flex and vibration, which cuts down on hollow-sounding footsteps and improves the perceived quality of the installation. Acoustic comfort is subtle, but occupants notice it — and appreciate it.

What installers and specifiers tell me

From conversations on site, two points come up again and again. First: installers value anything that reduces rework. Second: property owners value installations that stay reliable with little fuss.

Leg systems tick both boxes. They're quick to adjust, forgiving during installation, and they reduce hidden failures later. For specifiers, they're a low-cost choice that gives predictable results across multiple job types.

A few practical tips

- Check that legs are corrosion-resistant if used in moist environments.

- Level the tray properly using a spirit level and final fine adjustments with the legs.

- Keep a small service access area where feasible — even a tiny hatch helps.

- Consider heat and sound insulation when installing over timber floors.

- If reuse is possible, leg-mounted trays are easier to remove and reinstall during refurbishments.

Shower Tray Support Legs may be invisible after handover, but they do visible work. They protect finishes, simplify installation, support plumbing, and reduce long-term issues. For anyone building or renovating a bathroom, they are a practical detail worth specifying early in the design process.

How Do Shower Tray Support Legs Improve Long-Term Bathroom Stability

Most people never look under a shower tray. They don't need to — until something fails. Loose tiles, cracked grout, damp smells: these problems often start at the base. Support legs are small, simple parts. Yet they change how a shower behaves for years.

Stop movement before it shows up

Floors settle. Buildings shift a little over time. That's normal. The trouble starts when a tray sits on a spot that flexes or sinks. One corner doing all the work will put stress on tiles and seals.

Support legs spread the load across many points. Installers tweak each leg so the tray sits level. The result: less flex, fewer micro-cracks, and a finished surface that stays tidy longer.

Leveling on the job — fast and accurate

Mortar beds can work, but they're slow and messy. If the subfloor is uneven, you often have to build up or dig out. That eats time.

Leg systems let teams adjust height and tilt right on site. That makes matching drains and routing pipes simpler. No waiting for mortar to cure. No last-minute rework.

In practice, that saves hours on every job and reduces the chance of awkward fixes after tiling.

Moisture control you won't notice — until it's gone

Trapped moisture under a tray is a slow problem. It softens adhesives and corrodes timber. You won't see it for months, but the damage is real.

Raising the tray a little creates airflow underneath. That breathes the subfloor and helps any damp dry out. It's not dramatic, but it prevents a lot of hidden failures. Think of it as passive moisture management.

Spread the load — protect finishes and joints

Every shower use cycles weight and movement into the base. If that force hits one area repeatedly, materials fatigue. Tiles chip, edges break, silicone joints pull away.

Distributed support keeps those forces even. The tray flexes less. Grout stays intact. Seals remain snug. In high-use places — hotels or gyms, for example — that difference shows up quickly in reduced repairs.

Makes maintenance less painful

Plumbing rarely stays perfect forever. Drains clog, gaskets need checking, pipe joints leak. A fully mortared tray often means breaking tiles to access components.

A tray on legs with planned service access avoids that. Technicians can reach problem points without ruining the finish. Less demolition. Less downtime. Less upset customers.

That alone can justify using leg support on larger projects.

Helps keep things quiet

A hollow-sounding shower base is annoying in flats or hotels. It also signals flex in the structure.

Firmly supported trays vibrate less. Steps sound solid, not hollow. That adds perceived quality. People notice it even if they can't name why.

Simple tips installers use on site

- Check leg material for corrosion resistance in moist rooms.

- Level with a spirit level, then fine-tune with the legs.

- Keep a small access panel where possible — it saves hours later.

- Use insulation where timber floors might transmit sound or cold.

- Plan service routes before tiling to avoid surprises.

These are low effort and make a big difference later.

Why designers and builders specify them more often

Design trends favour slim trays and flush finishes. Those looks leave little margin for error. Legs give installers the margin they need without building up heavy bedding.

They also reduce material waste. You use less mortar and make fewer site adjustments. Over time that helps a project stay on schedule and budget.

Support legs are modest parts with outsized impact. They help level the tray, manage moisture, spread load, and keep maintenance simple. They also make flush designs more reliable and quieter underfoot.

Why Are Shower Tray Support Legs Gaining Attention In Renovation Plans

People renovating bathrooms want fewer surprises. Cracked grout, loose tiles, hidden leaks — these often start beneath the tray. That's why adjustable support legs are showing up more in renovation specs. They're a simple fix for a lot of common headaches.

Fixing uneven floors without demolition

Old floors rarely match the drawings. Timber can sag, concrete can slope, previous work can leave bumps. Pulling up the whole floor to level it takes time and money.

Support legs let installers adjust the tray on site. No big rebuild. No waiting for mortar to cure. Teams set each leg and get the tray perfectly level. For renovations, that saves days and keeps dust down.

Less rework after tiling

Rework is the worst part of a job. If a tray settles after tiles are laid, you'll see cracks or leaks later. With leg systems the tray stays stable. That means fewer callbacks and less upset from owners.

Moisture control that happens quietly

Trapped damp under a tray is a slow problem. You don't see it right away. Months later, adhesives fail and timber can rot.

A small gap under the tray improves airflow. Moisture dries out instead of sitting. It's a low-effort way to protect the subfloor and the finish above.

Quieter floors in flats and hotels

Hollow-sounding shower bases are a common complaint in multi-storey buildings. Legs reduce flex and vibration. Steps feel solid, not hollow. That improves perceived quality — guests notice it even if they don't know why.

Easier servicing when things go wrong

Pipes and drains need attention at some point. A fully mortared base often means breaking tiles to get in. A tray on legs with planned access makes life easier for plumbers. Less demolition, less mess, lower repair bills.

Design-friendly and efficient

Slim trays and flush thresholds are trendy. They leave little room for error. Adjustable supports let you achieve that look without risking the build. They also work well with linear drains, underfloor heating, or insulation layers.

Practical on-site tips

- Check leg material for corrosion resistance in wet rooms.

- Level with a spirit level, then fine-tune each leg.

- Keep a small service hatch where possible.

- Add insulation in timber floors to cut noise.

- Plan plumbing runs before tiling to avoid surprises.

When Should Contractors Replace Or Upgrade Shower Tray Support Legs

Renovation timing matters. Replacing or reinforcing the support system under a shower is one of those jobs that's easier and cheaper to do early. Wait until something fails, and the repair becomes messier and costlier.

Below are clear signals and practical moments when change makes sense.

Spot the warning signs early

Look for small clues during inspection. If you see any of these, take action:

- Cracks appearing at tray edges or in the nearest grout

- Slight movement when someone stands on the tray

- Soft or springy spots underfoot

- Persistent damp smells or staining near the base

- Joints or seals that pull away after light use

One sign alone might not force a replacement. Several together usually do. If something feels off, plan for repair rather than hope it will settle.

Best times to upgrade during a remodel

There are renovation stages when swapping out supports is efficient and smart:

- Full strip-out remodels — base is exposed, so replacement adds little extra labor.

- When changing floor finishes — you already have access to the subfloor.

- Drain repositioning — new drainage geometry often needs fresh leveling.

- After water damage repairs — replace any parts that were soaked or weakened.

- When converting a bath to a walk-in shower — different loads and clearances demand review.

If the job already exposes the tray area, upgrading is usually the right call.

Old materials don't always show their limits

Some older support methods hide damage until it's expensive to fix. Timber blocks can rot. Cheap plastics may crack. Metal parts can corrode where moisture collects.

Signs the existing kit has aged badly:

- Adjustable parts stick or won't hold position

- Corrosion on metal pieces or fittings

- Crumbling or soft timber beneath support points

- Brittle plastics or visible cracks

Use patterns change the game

A bathroom's use can evolve. A guest shower might become a daily-use facility. A family home could switch to short-term rental. Increased foot traffic shortens the life of an unchanged base.

Consider replacement when:

- The room's daily use will increase significantly

- Accessibility works add weight or altered traffic patterns

- A shower area is enlarged or reconfigured

- Matching support to actual use prevents premature wear.

Spend smart now to save later

It's tempting to patch and move on. That can backfire. Tiny movement under a tray lets moisture find weak spots. That damage spreads to subfloors, adhesives, and finishes. Fixing the fallout costs more than upgrading the support during the scheduled work.

Planned replacement:

- Reduces callbacks after handover

- Cuts hidden moisture risk

- Keeps tile finishes intact longer

For contractors, predictable outcomes mean fewer headaches and better reputations.

Quick on-site checks contractors rely on

Use these tests before deciding:

- Press test: apply weight near edges to feel for movement.

- Visual sweep: check for cracked grout or displaced joints.

- Tap test: hollow sounds can indicate poor contact or voids.

- Mechanism check: if adjustable parts don't move or lock properly, replace.

- Moisture check: damp or stained areas under or around the tray spell trouble.

If several tests fail, plan to replace the legs or the whole support system.

Replacement isn't always required. Use judgment. If the existing system is sound and matches the new design and use, keep it. If not, upgrade while you have access. The goal is stable performance, not unnecessary expense.

When in doubt, choose the path that reduces future work for you and future problems for the owner.

Practical Tips for Choosing Shower Tray Support Legs for New Bathrooms

When you plan a new bathroom, the visible finishes get most of the attention: tile patterns, taps, glass screens. What's easy to miss is what sits below the tray. Yet the right support system determines how the installation behaves for years. Get that wrong and you'll see grout cracks, damp spots, or loose tiles — problems that show up well after handover.

This article gives straightforward, site-tested advice for picking support legs that suit the room, the tray design, and the expected use. It's written for contractors, specifiers, and anyone responsible for reliable, low-hassle bathroom builds.

Start with the site survey, not the catalog

Before comparing products, walk the space. The subfloor, access routes, plumbing layout and intended use all shape your choice.

Key things to note on site:

- Subfloor type: concrete, timber, screed, or raised access. Each behaves differently under load and moisture.

- Level and flatness: small variations are normal; large dips or humps are a red flag.

- Drain location and fall requirements: where the water needs to go affects tray height and orientation.

- Future access: is this a private bathroom, or a room that may be repurposed or serviced often?

- Load pattern: is this a light-use ensuite or a heavy-use facility such as a gym shower?

A good site check prevents choosing a system that looks fine on paper but fails in practice. Invest ten minutes here — it saves hours later.

Why adjustability matters

The single most practical feature to demand is adjustability. Floors are rarely perfect, and plumbing doesn't always land exactly where drawings placed it. A support system that allows fine-tuning on site means the installer can achieve correct slope, perfect level, and tidy transitions without rebuilding the subfloor.

When assessing adjustable supports, look for:

- Smooth, incremental adjustment rather than coarse steps. You want to dial in the height precisely.

- A reliable locking method so the setting holds under load and over time. If the lock slips, the tray will move.

- Ease of access during installation — some systems require you to remove significant finishes to make adjustments; that's clumsy on a tight schedule.

- Serviceability: can parts be adjusted later without major demolition?

- Avoid systems that feel fiddly to set up; those often lead to mistakes on busy sites.

Match support to tray geometry

Not all trays are built the same. Some have flat undersides, others feature ribs or defined seating points. Matching the support design to the tray's underside reduces point loads and avoids stress risers that cause cracks or tile edge damage.

A few simple checks:

- Inspect the tray underside. Note whether contact areas are broad or localized.

- Choose supports that provide distributed support for flat bases and targeted contact for ribbed designs.

- If the tray manufacturer has a recommended support type, give that priority — many trays are designed with a certain support pattern in mind.

When tray and support are in harmony, the finished floor feels solid and the drainage stays consistent.

Consider moisture and corrosion resistance

Bathrooms are wet environments. Materials that resist rust and degradation pay back through longevity.

Material considerations:

- Metal parts should be stainless or have robust protective coatings in constantly damp areas.

- Plastics must be UV-stable and not become brittle after repeated wet-dry cycles.

- Timber blocks need to be treated and kept isolated from direct moisture.

It's also sensible to think about the salts that can be present in seaside locations or chemicals used in maintenance. Choose components that tolerate realistic site exposures rather than assuming the room will stay perfectly dry.

Sound and comfort: a real user concern

A tray that feels solid underfoot makes a house feel better. In multi-storey buildings, footsteps transmit as noise; hollow-sounding bases annoy occupants below.

Support details that reduce sound:

- Multiple support points that minimize flex.

- Dampening layers or thin insulation between supports and subfloor in timber installations.

- Firm locking mechanisms that avoid micro-movement every time someone steps in.

- Acoustic comfort is often a silent selling point — end users notice it, even if they don't mention it in feedback.

Think about maintenance access before you tile

Plumbing issues don't announce themselves politely. Drains clog, seals age, and joints loosen. If the tray is mortared solid without any access, fixing a problem can mean removing finished surfaces.

Plan for serviceability:

- Locate service hatches or removable panels where practical.

- Use support systems that allow limited access beneath the tray without full demolition.

- Where a hatch is impossible, ensure the plumbing layout is simple and reachable from elsewhere.

- Better access saves time and money years from now. It's a small planning step that avoids awkward, high-cost repairs.

Match the support choice to expected use

Not every bathroom needs the same level of reinforcement. A private ensuite sees far less wear than a hotel block or a gym changing room. Tailor the investment to the context.

Guiding principles:

- For light domestic use, a straightforward adjustable system with corrosion resistance and good locking may be enough.

- For frequent public use, choose more robust supports and consider redundancy — more support points spread the stress.

- For areas with heavier objects or accessibility aids (grab rails, seating) make sure the support system accounts for altered load patterns.

Right-sizing prevents overbuilding but also avoids under-specifying for tough conditions.

Material choices and their trade-offs

You'll encounter metal frames, polymer supports, composite systems and hybrid kits. Each has pros and cons.

Metals are strong and fixed in position; they can be heavier and need corrosion protection.

Engineering plastics are lightweight and resist moisture; older plastics can become brittle.

Composite supports combine elements to balance weight, strength, and durability.

Rather than sticking to brand claims, consider the installation context and ask for real-world references. A system used successfully in similar jobs gives more confidence than marketing copy.

Integration with underfloor systems

Modern bathrooms often include underfloor heating, insulation layers, and linear drains. These systems require space and careful planning.

Key points:

- Ensure the support height and clearance work with underfloor heating manifolds and fixings.

- Keep insulation continuity in mind; don't create thermal bridges that reduce heating efficiency.

- Linear drains may need particular fall or surround details — confirm how the support system accommodates them.

- A support solution that fits neatly with other services avoids rework and keeps systems accessible.

Supplier selection: what to ask for

A good supplier does more than ship parts. They support specification, provide documentation, and stand behind their product.

Ask suppliers for:

- Installation guides and recommended best practices.

- Case studies or references for projects similar to yours.

- Clarity on warranty terms and what they actually cover (serviceability, failure modes).

- Availability of spare parts and reasonable lead times.

A supplier's responsiveness matters on site. Quick, reliable support reduces delays and keeps projects flowing.

Site workflow: installation tips that prevent callbacks

Even a great product performs badly if installed sloppily. Standardize the workflow so crews produce consistent outcomes.

On-site best practices:

- Pre-check the tray underside and subfloor. Clean contact surfaces and remove debris.

- Dry-fit the supports first. Confirm alignment and drain position before any adhesive or permanent work.

- Level the tray using a spirit level and make fine adjustments with the supports. Small corrections now save large repairs later.

- Lock supports in place only after confirming drainage slope and perimeter alignment.

Document final settings. A photo and a short note help future servicing.

Leave access instructions for the client. Explain where service points are and how to reach them.

A disciplined approach reduces surprises and the need for re-visits.

Cost control without cutting corners

Budget pressures are real. Still, skimping on the support system often leads to expensive callbacks.

Ways to control cost:

- Standardize on a small range of compatible supports across jobs to buy in bulk.

- Train crews so installations are efficient and error-free. Time saved on site lowers labor costs.

- Use condition-led replacement strategy: replace supports only when inspection shows compromised performance, but plan for it during other works to avoid repeated access.