-

Why Is Choosing the Right Shower Bases Support Frame Essential for a Durable Bathroom

Nov 07, 2025

Bathroom renovations and installations require careful planning to ensure both functionality and durability. One often overlooked element is the foundation supporting the shower base. A well-designed Shower Bases Support Frame provides stability, reduces potential damage, and contributes to a longer lifespan for the shower area. This equipment has become increasingly popular in residential and commercial projects because it addresses common issues associated with weak or uneven shower bases.

Understanding the benefits, key selection considerations, and common installation mistakes can help homeowners, contractors, and designers make informed decisions. This article explores how to choose the right frame, why it enhances the performance of your shower base, and what to avoid during installation.

Why a Support Frame Matters

Stability and Weight Distribution

Shower bases must carry the weight of water, people, and sometimes additional materials such as tiles or stone overlays. A Shower Bases Support Frame distributes this weight evenly across the floor structure, preventing sagging or cracking over time. This even distribution ensures the shower base remains level and secure, avoiding small issues that could lead to expensive repairs if left unaddressed.

Longevity of the Shower Base

Without adequate support, shower bases can experience stress points that reduce durability. Over time, heavy usage or uneven flooring may lead to deformation or fractures. By installing a frame that provides continuous support beneath the base, the overall lifespan of the shower is improved. This benefit applies to both residential bathrooms and high-traffic commercial environments, where stability is critical.

Ease of Installation and Future Maintenance

Support frames simplify the installation process by offering a solid, level foundation. This minimizes the need for corrective adjustments during construction and reduces the likelihood of future problems. Additionally, many frames allow for easier access to plumbing components, making maintenance or repairs less disruptive and more efficient.

Key Considerations When Selecting a Shower Bases Support Frame

Choosing the right frame involves evaluating several factors to match the specific requirements of your project. The following elements should guide the decision-making process:

Consideration Reason Application Material Determines durability and resistance to moisture Aluminum, stainless steel, or reinforced plastics are common options Weight Capacity Ensures the frame can handle full load safely Suitable for tiled or stone shower bases Compatibility Matches the dimensions and shape of the shower base Rectangular, square, or custom shower designs Adjustability Allows leveling on uneven floors Residential renovations or retrofit projects Ease of Installation Reduces time and labor during setup DIY projects and professional installations This table provides a structured view of the most critical features to evaluate when selecting a Shower Bases Support Frame, helping ensure that the foundation meets both immediate and long-term needs.

Common Installation Mistakes and How to Avoid Them

Even with the right frame, improper installation can compromise its benefits. Understanding common pitfalls helps ensure the frame performs effectively.

Ignoring Floor Leveling

A frame installed on an uneven or unstable floor will not provide proper support. Before installation, it is essential to verify that the subfloor is level. Minor adjustments may be required to accommodate slopes or irregularities. This step prevents stress points and uneven weight distribution on the shower base.

Incorrect Fastening or Spacing

Frames must be secured according to recommended guidelines. Improper spacing or insufficient fastening can result in movement under load, leading to cracks or structural issues. Ensuring that the frame components are properly aligned and tightened is crucial for long-term stability.

Neglecting Material Compatibility

Not all shower bases are compatible with every type of frame. Choosing a frame without considering the base material can result in uneven support, warping, or reduced durability. It is important to match the frame to the specific type of base—whether acrylic, fiberglass, or stone composite—to achieve optimal results.

Overlooking Maintenance Access

A frame should not obstruct access to plumbing or drainage systems. Designers and installers must plan for convenient maintenance without removing the entire frame, saving time and avoiding unnecessary work during future repairs.

Additional Benefits of Using a Support Frame

Enhanced Safety

A properly supported shower base reduces the risk of accidental tipping, cracking, or uneven flooring. This safety aspect is particularly important in homes with children, elderly residents, or high-traffic commercial settings.

Improved Workflow During Installation

Support frames streamline the installation process by providing a consistent level and stable foundation. This efficiency helps installers complete projects faster, reduce material waste, and avoid the need for repeated adjustments.

Environmental Considerations

Durable frames made from corrosion-resistant or recyclable materials support sustainable construction practices. By extending the lifespan of the shower base, these frames contribute to less frequent replacements and reduced material consumption over time.

Selecting the right Shower Bases Support Frame is an essential step in achieving a stable, long-lasting, and safe shower installation. By considering factors such as material, weight capacity, adjustability, and compatibility, homeowners and contractors can ensure the foundation meets project requirements and supports long-term performance. Avoiding common installation mistakes—such as improper leveling, incorrect fastening, and mismatched materials—further enhances the benefits of the frame.

A well-installed support frame improves weight distribution, reduces stress on the shower base, and simplifies maintenance. It also contributes to overall safety and efficiency during installation, making it a valuable addition to both residential and commercial bathroom projects. Investing in the right frame not only protects the shower base but also supports practical and sustainable bathroom management practices.

-

The Hidden Hero Behind Every Stable Shower Tray Why Smart Installers Choose CE-Certified Steel Anchors for Bathtubs and Trays

Nov 05, 2025

When it comes to bathroom installations, the visible elements—tiles, faucets, and finishes—often steal the spotlight. But professionals know that true quality lies in the details behind the scenes.

One of those unsung heroes?

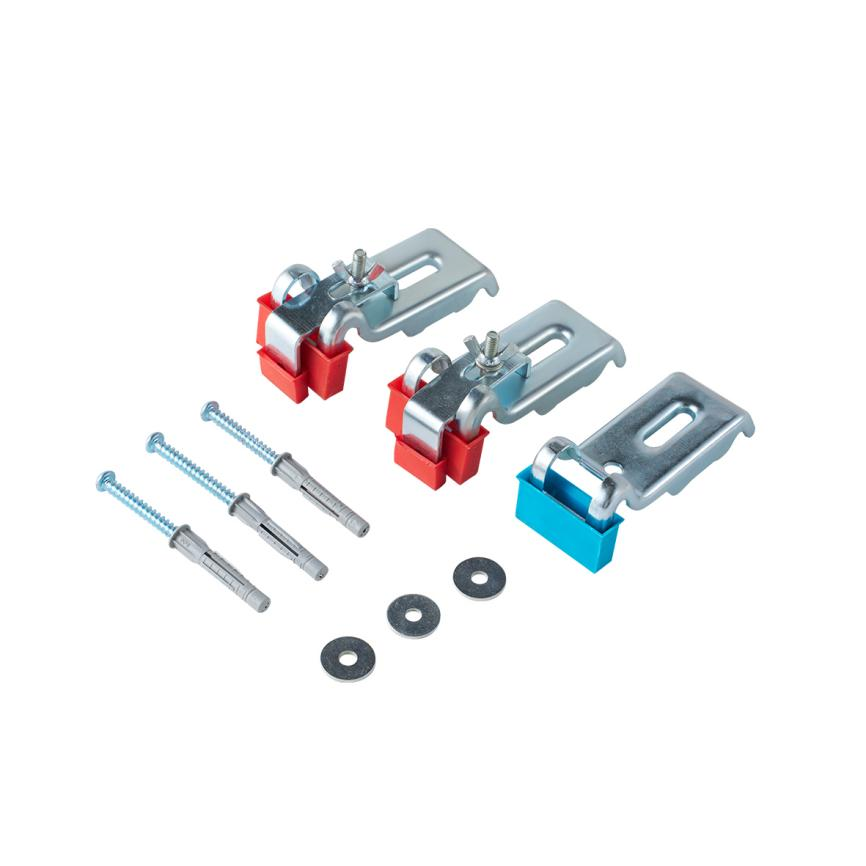

The CE-certified steel supporting anchor for shower trays and bathtubs.

Engineered for Strength, Built for Silence

This isn't just another piece of hardware. It's a smart solution designed to do one job perfectly: secure your steel or enamel shower tray or bathtub to the wall—tightly, quietly, and reliably.

With a reinforced steel body, anti-noise support surface, and adjustable height mechanism, this 3-piece anchor set delivers rock-solid stability with none of the squeaks or rattles

What Makes It Stand Out?

Universal Fit

Compatible with most steel or enamel trays with edge thickness around 2.3 mm.

All-in-One Kit

Comes with 1 universal anchor, 2 clamp-style anchors, and complete installation accessories.

Quick Adjustment

Fine-tune height effortlessly using the knurled screw, perfect for uneven walls.

Noise Control

Special support pads reduce vibration and noise for a better user experience.

CE Certified

Meets European quality and safety standards for global projects.

A Small Part That Makes a Big Difference

Installers love it for how fast and easy it is to mount.

Distributors love it for its CE compliance and export readiness.

OEM manufacturers love it because it solves a real-world problem simply and affordably.

Whether you're fitting out a hotel bathroom or supplying a full housing project, this small anchor kit delivers big peace of mind.

Perfect for:

Sanitary ware distributors & wholesalers

Bathroom remodeling contractors

New construction or renovation projects

Shower tray and bathtub OEM packaging

Ready to Ship. Easy to Customize.

We can supply this product in bulk, customize the packaging for your brand, or include it as part of a complete installation kit. Whatever your project needs, we're ready to support.

Want to learn more or request a sample?

Reach out today and discover how this simple accessory can help you deliver cleaner installs, fewer callbacks, and happier clients.

For more information, please visit: https://www.yh-jinyi.com/

-

How Can JINYI Decoupling Tank Reduce Pump Energy And Enhance Performance

Nov 03, 2025

The Decoupling Tank plays a pivotal role in modern building energy systems, acting as a hydraulic buffer to separate primary and secondary circuits. By stabilizing water flow, it reduces energy consumption from circulation pumps and allows heating and cooling systems to maintain consistent performance across all zones. Incorporating this type of buffer ensures smoother energy distribution and improved operational efficiency, which is essential for residential, commercial, and industrial applications.

In buildings without proper hydraulic separation, sudden changes in flow demand can lead to some zones receiving excessive water while others remain under-supplied. This imbalance forces pumps to work harder, consuming more electricity and causing fluctuations in temperature that affect comfort levels. A correctly sized decoupling tank allows the system to maintain stable operation, enabling pumps to run at optimal speeds and preventing unnecessary energy loss.

Energy efficiency benefits from multiple mechanisms. Flow stabilization reduces the need for high-speed pump operation, directly lowering energy costs. Consistent water delivery ensures heat exchangers perform efficiently, maximizing thermal transfer and system performance. Pressure spikes are minimized, reducing wear on pipes, valves, and pumps, and extending the lifespan of critical system components.

The tank also enhances system maintenance and reliability. Maintenance personnel can isolate either the primary or secondary circuit without disrupting the entire setup. This modular design allows for safer inspections, faster component replacement, and reduced downtime. Additionally, it prevents water hammer, air accumulation, and other hydraulic problems that could otherwise damage the system.

Advanced energy-efficient systems integrate decoupling tanks with variable-speed pumps and smart controls. This combination allows precise regulation of water flow, ensuring all areas receive adequate supply regardless of load variations. In multi-zone commercial buildings, the tank helps maintain uniform temperatures, improving occupant comfort while reducing electricity usage.

Optimal tank selection is critical. An undersized tank cannot buffer flow properly, while an oversized tank occupies unnecessary space and may increase costs. Engineers calculate appropriate tank size based on expected load fluctuations, system flow rates, and temperature differentials to achieve a balance between efficiency and practicality.

JINYI has developed decoupling tank solutions tailored to meet these operational requirements. Their designs support smooth hydraulic operation, reduce energy usage, and ensure reliable system performance, making them suitable for diverse applications in residential and commercial buildings.

-

Can a Decoupling Tank Redefine Energy Efficiency in Modern Buildings

Oct 31, 2025

Understanding the Role of a Decoupling Tank

A Decoupling Tank plays a vital role in improving the efficiency and balance of modern HVAC and hydronic systems. It separates the primary and secondary circuits, ensuring smoother energy transfer and minimizing mechanical strain. By stabilizing flow and temperature, this technology supports energy-saving operations and enhances comfort in both commercial and residential environments.

Reducing Flow Conflicts Between Circuits

Traditional HVAC systems often struggle with flow imbalances, where pumps and chillers compete for water circulation. This results in unstable temperatures and wasted energy. A decoupling tank acts as a neutral zone, maintaining consistent flow between circuits and preventing unnecessary strain on system components.

Achieving Operational Stability

By allowing independent operation of both loops, the system avoids frequent pressure changes. Stable flow means less pump power is needed, reducing both energy use and operational costs. It also minimizes equipment cycling, extending the service life of key HVAC elements.

Enhancing Energy Efficiency Through Flow Stabilization

The main advantage of decoupling lies in its ability to stabilize water flow and maintain thermal equilibrium. When hydraulic systems are balanced, temperature regulation becomes more accurate, allowing buildings to maintain comfortable indoor environments with less energy waste.

JINYI focuses on developing efficient tank systems that meet the growing demands of energy-aware industries. Through reliable design and quality manufacturing, these tanks provide consistent performance and align with sustainable energy practices.

Optimizing Temperature Control and System Management

Ensuring Thermal Consistency in Large Buildings

In larger facilities, maintaining temperature balance is challenging. The decoupling process allows each loop to adjust independently, ensuring consistent comfort without overburdening the system. This separation also enables better monitoring and control of flow rates and temperature gradients.

Simplifying Maintenance and Testing

A decoupling tank makes it easier to commission, inspect, and fine-tune hydronic systems. By providing a steady flow environment, engineers can perform maintenance or adjustments without interrupting daily operations, resulting in improved reliability and long-term cost control.

Supporting Sustainable Building Performance

Energy-efficient design is a cornerstone of modern construction. Incorporating decoupling tanks helps buildings meet energy conservation targets while supporting environmental sustainability. These tanks reduce energy loss, stabilize performance, and contribute to reduced carbon emissions over time.

As energy management becomes increasingly important, the inclusion of decoupling tanks is a practical step toward long-term sustainability. JINYI continues to innovate in this field, providing building system components that reflect both technical reliability and environmental responsibility.

Building Toward Smarter Energy Solutions

Integrating decoupling tanks into HVAC systems enhances overall performance, improves operational stability, and supports sustainable goals. With growing attention to energy efficiency, these components have become an essential part of modern building infrastructure.

-

Stick, Adjust,Support The Smart Way to Install Acrylic Bathtubs - ADS System Self-Adhesive Adjustable Leg Sets

Oct 29, 2025

Speed matters on the job site. And so does reliability. That’s why more installers are switching to our ADS System (Anti-rotation and soundproofing system) Self-Adhesive Adjustable Bath Leg Sets - the smarter, faster way to mount acrylic bathtubs.

With a strong self-adhesive base and adjustable leg height up to 180 mm, this innovative support system combines easy installation with firm, lasting support- no drilling, no complex framing, no wasted time.

Designed for Fast Installs. Built for Stability.

Forget messy sealants or improvised mounting hacks. The ADS leg set comes ready with industrial-grade adhesive backing, allowing for secure placement directly onto the bathtub base. The adjustable legs provide the necessary height flexibility to level your tub effortlessly, even on uneven subfloors.

Whether you’re installing in a home renovation or a multi-unit housing project, this system helps you deliver consistent results — faster.

Key Features & Benefits

Self-Adhesive Mounting

Simply peel and stick — no need for extra fasteners or brackets.

Height Adjustable (up to 180 mm)

Get the perfect level every time, even on irregular flooring.

Quick Installation

Reduces labor time and complexity — ideal for high-volume projects.

Sturdy, Lightweight Design

Engineered for acrylic bathtubs, offering solid support without added bulk.

Clean Finish, Less Noise

Supports the tub evenly to reduce creaking or shifting during use.

Perfect for:

Acrylic bathtub manufacturers & OEM kits

Bathroom renovation professionals

Real estate and apartment installations

Sanitary ware importers and distributors

Why Installers Love It

“The adhesive backing is a game-changer. It sticks firmly and saves at least 15-20 minutes per install. Great for multi-unit jobs where time is everything.”

— Installer feedback from a UK housing project

Flexible Supply Options Available

We offer fast shipping for bulk orders, OEM packaging, and custom specifications to match your brand or project needs. Whether you’re serving the local market or exporting globally, we’re ready to support your supply chain.

Fast to install. Strong to support. Smart to choose.

Upgrade your acrylic bathtub installations with the ADS Self-Adhesive Adjustable Leg Set — the future of bathroom fitting starts here.

For more information, please visit: https://www.yh-jinyi.com/

-

How Does a JINYI Shower Tray Leg Frame Improve Bathroom Stability

Oct 27, 2025

A Shower Tray Leg Frame is one of the most important elements for ensuring a stable and long-lasting shower installation. By providing even weight distribution and structural support, it prevents shifting, cracking, and water leakage that can damage floors or surrounding bathroom structures. Choosing a reliable frame can improve both safety and convenience, especially in homes or commercial properties with high shower usage.

Before beginning installation, the subfloor must be clean, level, and free from debris. An uneven surface can compromise the tray's stability, leading to stress points and potential damage. Adjustable legs in modern frames allow for precise leveling, even accommodating minor irregularities in flooring. This adjustment capability ensures that the shower tray remains stable over time, reducing maintenance concerns and improving the overall longevity of the installation.

JINYI's Shower Tray Leg Frame combines durable materials with practical design, making it easier for installers to achieve a secure fit. Reinforced connectors, corrosion-resistant metals, and robust engineering guarantee that the tray remains firmly in place. The frame is compatible with a variety of tray sizes, offering flexibility during renovation or new construction projects. Whether installing a shower in a residential bathroom or a commercial facility, this frame supports consistent performance and stability.

During installation, measurement and alignment are crucial. Using a spirit level helps confirm that the frame is perfectly horizontal, while each leg should be adjusted to ensure uniform support across all contact points. After positioning, sealing the tray edges with waterproof silicone is recommended to further protect against moisture intrusion, which can weaken floors and reduce the tray's lifespan.

The benefits of a proper frame extend beyond stability. A well-supported tray ensures user safety by preventing wobbling or tilting when entering or exiting the shower. It also simplifies cleaning and maintenance, as a stable tray reduces the risk of water pooling or gaps forming under the tray. From a design perspective, a sturdy frame contributes to a polished, professional appearance, complementing modern bathroom aesthetics.

For homeowners and professional installers, understanding the value of a reliable shower tray support frame is essential. Selecting the right product can prevent costly repairs, maintain structural integrity, and improve the overall usability of the shower. High-quality frames are particularly important in bathrooms with heavy usage or frequent exposure to moisture, as they provide lasting reliability.

Proper installation is equally important. Following step-by-step guidelines ensures that each leg is correctly positioned, the tray sits level, and all connections are secure. Adjustable frames allow installers to make minor adjustments to achieve perfect alignment, which is critical for preventing leaks and uneven wear over time. This attention to detail enhances both safety and longevity, giving users confidence in their bathroom setup.

Investing in a durable, well-engineered support frame is a smart decision for anyone looking to maintain a high-quality shower system. By reducing stress points and distributing weight evenly, the frame protects both the tray and the underlying floor. This prevents common problems like cracking, shifting, and water damage, saving time and costs associated with future repairs.

A Shower Tray Leg Frame also adds versatility to the installation process. Its adaptability allows it to work with different tray materials, sizes, and bathroom layouts. This flexibility makes it suitable for a wide range of projects, from small home renovations to large commercial installations. Using a frame designed for durability and adjustability ensures consistent results, even on uneven surfaces.

-

Why Is Choosing the Right Shower Tray Support Frame Important for Stability

Oct 24, 2025

Choosing a Shower Tray Support Frame for a bathroom setup might appear simple, but selecting the right one can significantly affect stability and user experience. A carefully designed support frame keeps the tray secure, reducing unnecessary movement and protecting surrounding structures over time. Both homeowners and professional installers notice the difference when a tray rests on a solid, dependable base.

One key advantage of a proper frame is even load distribution. Supporting the tray uniformly prevents pressure points that could lead to cracks or uneven surfaces. This is especially important in bathrooms with heavier tiles or frequent use, where stress might otherwise accumulate. The correct frame minimizes potential tray deformation and helps prevent water seepage.

Flexibility and ease of installation are additional benefits. Modern support frames often accommodate various tray sizes and bathroom layouts. Adjustable legs or modular elements allow precise leveling, simplifying the installation process. This adaptability reduces installation time and eliminates the need for extra reinforcement, saving both materials and effort.

Maintenance becomes simpler when the tray is well-supported. Cleaning around and beneath the installation area is easier, and routine checks for stability require less effort. A firm frame reduces vibrations and shifting that might otherwise loosen fittings or wear out surrounding components, supporting long-term durability.

Safety is another important consideration. A stable shower base prevents sudden tray movement during use, reducing slip risks. Even slight adjustments in alignment or height can improve comfort and confidence. For households with children or elderly members, this stability contributes to safer, more reliable daily use.

Long-term durability is enhanced by investing in a quality frame. Choosing the appropriate product decreases the likelihood of future repairs or replacements. A reliable support system ensures consistent performance and provides peace of mind for homeowners.

Selecting the right support frame goes beyond a single component decision—it affects overall shower functionality, safety, and comfort. By evaluating material quality, adjustability, and structural design, one can achieve a balanced installation that delivers reliable performance for years.

-

Stable from the Ground Up The Cross-Style Shower Tray Support Frame That Installers Trust

Oct 22, 2025

In the world of bathroom construction, a perfectly installed shower tray is a mark of true craftsmanship. But even the best trays can’t perform without solid, reliable support underneath.That’s where our Five-Screw Cross Style 100cm Shower Tray Support Frame comes in — the hidden foundation that ensures your tray stays flat, level, and built to last.

Built for Strength. Designed for Speed.

This cross-shaped metal frame is engineered for maximum stability and ease of use. With five adjustable screws, it offers exceptional weight distribution across the base of the shower tray, reducing stress points and preventing cracking or warping over time.

Whether you're a professional installer or a sanitary ware brand looking for a high-quality OEM solution, this support frame helps you build better, faster, and smarter.

Key Benefits

Strong Cross-Style Structure

The metal frame provides reinforced support across all key pressure points of the shower tray.

Five-Point Adjustable Screws

Precision height adjustment ensures perfect leveling—even on uneven floors.

Fast & Simple Installation

Designed for efficient assembly, saving time on-site without compromising strength.

100cm Size

Ideal for standard-size shower trays; can also be customized for OEM needs.

Durable Construction

Made from corrosion-resistant materials for long-term reliability.

Why Professionals Choose This Frame

“It just works.”

Installers love this frame because it reduces installation errors, improves tray stability, and speeds up the process. And when paired with wall anchors or adjustable legs, it offers a complete installation system that meets the demands of both small bathroom jobs and large housing projects.

Perfect for:

Shower tray manufacturers (OEM integration)

Bathroom fitters and renovation contractors

Real estate & hotel bathroom projects

Sanitary ware distributors and importers

Ready for Bulk Orders & Custom Branding

We offer flexible supply options, including OEM packaging, custom sizes, and fast lead times for bulk orders. With years of experience exporting to Europe and beyond, we’re ready to support your next project with dependable quality and service. For more information, please visit: https://www.yh-jinyi.com/

-

How Can You Choose the Right Frame Height for a Shower Tray Leg Frame Installation

Oct 20, 2025

Choosing the Right Frame Height for a Shower Tray Leg Frame Installation

Installing a shower tray is one of the final yet most critical stages of a bathroom renovation. The process involves both technical precision and visual coordination. Among the many steps required, determining the appropriate frame height for the leg frame installation is particularly important. The height not only affects how well the tray functions but also how it aligns with the surrounding features, such as walls, tiles, and enclosures. A correctly chosen frame height ensures structural balance, proper drainage, and comfortable use over time.

Understanding the Purpose of a Leg Frame

A shower tray leg frame is designed to provide firm support and stability beneath the tray. It distributes the load evenly across the floor, preventing movement or flexing when the shower is in use. This structure also creates a gap beneath the tray, allowing room for waste pipes, traps, and drainage components. Without this clearance, connecting the plumbing system becomes difficult and may cause long-term maintenance problems.

The height of the frame determines how much space is available beneath the tray for pipework and water flow. If the frame is too low, the drainage system may not perform efficiently. If it is too high, it could alter the appearance of the shower area or make access less convenient. Finding a balanced height that suits both practicality and aesthetics is therefore essential.

Factors That Influence Frame Height Selection

There is no universal frame height that fits every bathroom, as each installation is influenced by different factors. Understanding these variables before starting the project helps ensure the installation process runs smoothly.

Drainage and Water Flow

Proper drainage depends heavily on gravity. The waste pipe needs a gentle downward slope to allow water to exit freely. When setting the frame height, enough clearance must be provided beneath the tray to achieve this slope without creating sharp bends or restrictions. A thoughtful design at this stage prevents water buildup and promotes smooth operation.

Bathroom Floor Structure

Every bathroom has a unique subfloor composition. Concrete, timber, or composite materials each behave differently under weight and moisture exposure. These materials can affect how the leg frame sits and how adjustments are made during installation. Uneven floors might require fine-tuning at individual leg points to achieve a level surface. Taking time to examine the base before setting the frame avoids complications later in the process.

Accessibility and Comfort

The height of the tray affects how easily someone can step in and out of the shower. A frame set too high might make access uncomfortable, especially for children or elderly users. Conversely, a frame that is too low could reduce the clearance for drainage. A balanced approach ensures that both comfort and functionality are maintained, creating a practical and safe shower experience for everyone.

Visual Proportion and Design Harmony

Bathrooms often feature integrated designs where tiles, screens, and fixtures follow a visual rhythm. The frame height determines how the tray lines up with other elements, influencing overall appearance. When the tray sits at a proportional level with the floor and wall finishes, the result looks cohesive and intentional. Aligning these details enhances the visual flow of the room and contributes to a refined finish.

The Role of Adjustment During Installation

Even with careful planning, fine adjustments are usually necessary once installation begins. Adjustable legs on the frame allow small height modifications to achieve precise leveling. Each leg should be firmly positioned to maintain even weight distribution. It's important to ensure that the entire tray surface remains steady without rocking or shifting. Once the correct height and balance are confirmed, the tray can be secured.

During this stage, checking alignment with both the wall and the drain outlet is essential. A misaligned tray could result in water accumulation or cause the enclosure to fit incorrectly. Regular use of a spirit level helps maintain accuracy as each leg is adjusted. It is also beneficial to dry-fit the waste system before permanently fixing components to confirm adequate clearance.

Drainage Coordination and Pipe Clearance

The relationship between frame height and plumbing is fundamental. Insufficient space beneath the tray can lead to tight bends in the waste pipe, which may slow water flow or create blockages. Ensuring that there is enough vertical clearance allows for smoother water passage and easier access for future maintenance.

Additionally, the trap and outlet need to be aligned with the waste hole of the tray. Proper alignment avoids unnecessary stress on joints and reduces the risk of leaks. Setting the frame at a well-considered height simplifies this connection process and minimizes long-term issues.

Ensuring Long-Term Stability

The height you choose also contributes to how the entire shower structure withstands daily use. A frame that is too high or unevenly set can place strain on both the tray and surrounding tiles. Over time, this may result in cracks or loosening. To prevent this, installers often reinforce key points beneath the tray to strengthen the support.

It is equally important to verify that the frame legs rest securely on a firm surface. Floors that are soft or irregular might require reinforcement or leveling compounds before installation begins. A stable foundation promotes longevity and reliability, keeping the shower tray solidly in place for years.

Finishing Touches and Visual Details

Beyond function, attention to finishing details can elevate the appearance of the entire shower area. The visible edges of the tray should align neatly with nearby surfaces, and any sealing should be applied smoothly. The height of the frame influences how the side panels and skirting fit. Ensuring even spacing along the perimeter contributes to a clean, professional finish.

When combined with consistent tile lines and properly fitted enclosures, a well-positioned tray height creates a balanced, polished aesthetic. This combination of precision and design awareness enhances both practicality and style.

Avoiding Common Installation Mistakes

A few frequent errors can occur if the frame height is not carefully chosen or checked. Setting the tray too low may restrict access to the waste system, making repairs or cleaning more difficult. Placing it too high can disrupt the room's proportions or require unnecessary steps to enter. Overlooking the slope of the waste pipe may also cause drainage inefficiency.

To prevent these issues, it helps to perform a full layout check before securing any part of the installation. Measuring, testing, and adjusting in advance can save time and avoid rework later.

The Value of Proper Planning

Proper preparation before installation often determines the final quality of the result. Reviewing measurements, studying the floor layout, and verifying pipe positions make the process more efficient. It is beneficial to have all components—tray, waste system, and enclosure—on-site before beginning. This allows for accurate alignment and immediate adjustments if required.

When both functionality and design are considered equally, the shower installation achieves a balance between usability and appearance. Planning every detail, from frame height to drainage angle, ensures a consistent and lasting outcome.

Choosing the right frame height for a shower tray leg frame installation involves a combination of technical knowledge and visual awareness. The correct height supports drainage performance, enhances stability, and contributes to overall comfort. It also helps achieve a unified look that integrates with the surrounding bathroom design.

By taking time to plan and adjust before final installation, the process becomes smoother and more precise. Each element—from the positioning of the legs to the alignment of the drainage—plays a role in ensuring long-term reliability. A carefully selected frame height not only supports the structure beneath but also enhances the shower experience above, resulting in a balanced and durable installation that performs well over time.

-

How JINYI Water Meter Bracket Ensures Reliable Plumbing System Performance

Oct 17, 2025

When installing or upgrading plumbing systems, a Water Meter Bracket plays a crucial role in maintaining stability and precise positioning of water meters. This seemingly simple component is essential for both residential and commercial applications, as it ensures accurate measurement of water usage while providing long-term structural support. Proper installation not only secures the water meter but also prevents unnecessary strain on the connected pipes and fittings.

Why Bracket Selection Matters

Choosing the right bracket can have significant effects on performance and durability. Materials used in manufacturing, load-bearing capacity, and resistance to environmental factors such as moisture or corrosion all contribute to the reliability of the installation. A sturdy bracket reduces the risk of misalignment, which can interfere with water readings and lead to maintenance issues down the line.

In addition to functional stability, brackets also contribute to organized plumbing setups. They help maintain a neat alignment of pipes and meters, making inspections, repairs, or replacements more straightforward. For large buildings with multiple meters, consistent bracket usage ensures uniformity across installations, simplifying management for maintenance personnel.

Installation Considerations

Correctly positioning a water meter bracket involves assessing the surrounding area and securing the support at a level that prevents tilting or sagging. Over time, vibrations from water flow or accidental contact can loosen poorly installed brackets, potentially causing damage to meters or connected pipes. Ensuring that the bracket is fastened firmly with appropriate screws or bolts is crucial for maintaining system integrity.

Additionally, installers must consider accessibility. A well-placed bracket allows easy access to the meter for reading or servicing, reducing the need for disruptive disassembly. This is particularly important in commercial or industrial environments where frequent monitoring is required.

Enhancing Longevity Through Quality Materials

Advancements in bracket materials have focused on corrosion resistance, mechanical strength, and ease of installation. For example, coated metals or high-grade alloys provide protection against rust, while lightweight yet durable composites can simplify handling without compromising strength. Choosing the right material is essential for installations exposed to outdoor elements or high-humidity environments.

Regular inspections are also recommended to ensure that brackets remain secure and free from damage. Detecting early signs of wear or loosening allows timely adjustments before significant issues arise, thereby extending the lifespan of the water meter and its support system.

The Broader Impact on Plumbing Systems

A water meter bracket is not just a passive accessory; it directly affects the performance of the plumbing system. Properly supported meters maintain accurate readings, which in turn helps in monitoring water consumption, identifying leaks, and managing utility costs efficiently. Moreover, stable brackets reduce stress on pipelines, preventing premature wear and enhancing overall system durability.

Homeowners and facility managers should consider bracket quality as an investment in the longevity and reliability of their plumbing infrastructure. Proper installation, combined with routine maintenance, ensures that water meters remain functional and secure for years to come.

Selecting and installing a reliable Water Meter Bracket is a small but vital step in maintaining effective water management systems. By ensuring stability, easy access, and long-term durability, these components support accurate readings and reduce maintenance challenges. For anyone considering an upgrade or new installation, prioritizing bracket quality can make a meaningful difference in the overall performance of their plumbing infrastructure.

-

Quiet Strength Beneath Every Bath Sound-Insulation Adjustable Bath Leg Sets for Acrylic Bathtubs up to 180×80 cm

Oct 15, 2025

Behind every great bathtub is a foundation you can trust — one that holds firm, levels easily, and works quietly in the background. Our adjustable bath leg set is exactly that: a smart, durable, and noise-reducing support system for acrylic bathtubs up to 180×80 cm.

Designed for fast installation and long-term reliability, this leg set helps installers save time while delivering rock-solid stability and a more peaceful bathing experience for end users.

Built to Support. Engineered for Comfort.

Made from galvanized steel and high-grade plastic, the legs are height-adjustable and come with sound-insulation pads that reduce vibration and noise transfer to the floor — a major plus in multi-story housing or hotel installations.

Whether you're a contractor, retailer, or OEM partner, this kit ensures your bathtubs are installed safely, quietly, and professionally.

Key Benefits

Fits Bathtubs up to 180×80 cm

Perfect for most standard acrylic bathtubs — ensuring wide compatibility.

Noise-Reducing Pads

Built-in insulation pads help minimize vibration and structure-borne sound, improving user comfort.

Height Adjustable Legs

Level your bathtub easily on uneven floors — no additional tools or base framing needed.

Sturdy Galvanized Steel Support Bars

Provides long-lasting strength and corrosion resistance in damp environments.

Quick, Easy Installation

Delivered with all necessary hardware and pre-mounted connections for faster workflow.

Ideal For:

Residential bathroom installations

Hotel and apartment projects

OEM acrylic bathtub packaging

Sanitary ware wholesalers and importers

What Makes It Different?

Unlike traditional wooden framing or DIY leveling hacks, this adjustable leg system gives you a clean, modern solution that reduces labor costs and enhances the end-user experience. It’s what today’s professional installers are looking for.

Flexible Supply & OEM Options Available

Whether you need bulk orders for your warehouse, private-label kits for your own brand, or custom packaging to match your acrylic tubs, we’ve got you covered. Our products are CE-compliant and ready for global export.

Better support. Less noise. Happier customers.

Upgrade your bathtub installations with the leg set that delivers behind-the-scenes reliability — every single time. For more information, please visit: https://www.yh-jinyi.com/

-

Are Shower Tray Leg Frames Redefining the Future of Bathroom Installations

Oct 13, 2025

In the evolving world of interior construction, bathroom design has become one of the most dynamic areas for innovation. Homeowners, architects, and installers are continually searching for practical solutions that combine function, adaptability, and ease of installation. Among the most notable developments in recent years are riser kits and adjustable shower tray leg frames, two systems that have significantly influenced how modern bathrooms are built and maintained.

Both serve a crucial purpose — supporting shower trays and managing drainage systems — yet they differ in structure, flexibility, and long-term performance. Understanding their roles and comparing their functions reveals how these installation systems are reshaping the standards of bathroom construction.

The Rise of Adaptable Installation Systems

Modern renovation projects prioritize flexibility. Homes today are built with a mix of materials — concrete, timber, and composites — each presenting different challenges during bathroom installation. Uneven floors, limited access to plumbing, and changing design preferences require adaptable support systems.

Adjustable shower tray leg frames emerged as a solution to these evolving needs. Unlike traditional fixed bases, these frames allow precise height adjustments for each leg, creating a level surface even on irregular flooring. For installers, this innovation simplifies alignment and reduces preparation time, eliminating the need for extensive subfloor modifications.

Meanwhile, riser kits have maintained their relevance by offering a simple way to elevate a shower tray, particularly in buildings where the subfloor cannot be altered. They raise the tray just enough to allow pipework and drainage to fit comfortably below, making them practical for solid or concrete flooring situations.

Comparing Function and Application

While both systems aim to provide stability and support, their differences influence how and where they are used.

Riser kits provide a fixed, enclosed base that lifts the tray above the floor. Once installed, the structure remains stable but lacks flexibility for later adjustments. They are often chosen for their clean finish and straightforward setup, especially in uniform environments such as hotels or apartment buildings where maintenance access is limited.

Adjustable shower tray leg frames, on the other hand, bring customization to the installation process. Each leg can be individually altered to achieve perfect leveling, an advantage when working with uneven or sloped floors. The design also allows easy access underneath the tray, making future maintenance or pipe adjustments far simpler.

This difference — fixed simplicity versus adjustable flexibility — defines the choice for many installers and homeowners.

Addressing Installation Challenges

Uneven flooring is one of the most frequent issues in both new constructions and renovations. Without proper support, even a small imbalance can cause stress points, leading to cracks or water leakage over time. Adjustable leg frames solve this problem by distributing the weight evenly and maintaining a stable platform underfoot.

Moisture management is another critical consideration. Bathrooms are naturally humid environments where small imperfections in installation can lead to long-term damage. Both riser kits and adjustable frames help keep the tray elevated, ensuring that water does not accumulate underneath and that ventilation remains possible.

However, leg frames often stand out for accessibility. When plumbing issues arise, their open design allows for direct maintenance without removing the entire shower tray — an advantage that riser kits cannot always offer.

Evolution of Design and Material Quality

As the popularity of these systems has grown, so has the innovation behind their materials and construction. Manufacturers now design frames with corrosion-resistant metals, reinforced brackets, and lightweight components that enhance both durability and ease of handling.

Adjustable leg frames, in particular, have evolved with smoother height control mechanisms and anti-vibration bases that reduce movement during use. These developments reflect a shift toward ergonomic installation and long-term stability rather than one-time setup convenience.

Riser kits, meanwhile, have seen improvements in design aesthetics. Modern versions integrate neatly with the tray, offering a uniform appearance that conceals plumbing while maintaining a compact footprint. This makes them appealing in minimalist bathrooms where visible structural elements are reduced.

Benefits for Homeowners and Professionals

From a homeowner's perspective, both systems contribute to greater comfort and longevity. A stable, well-supported shower base enhances the sense of safety and durability, ensuring that daily use remains reliable. Adjustable leg frames are especially appealing to those who value long-term maintenance access — a key advantage when remodeling in stages or making future upgrades.

For installers and contractors, the benefits are just as clear. Adjustable systems save time during setup, particularly when dealing with irregular subfloors. They allow fine-tuning and on-site corrections that reduce installation errors. Riser kits, on the other hand, are appreciated for their predictability — an important factor in large-scale developments where consistency is key.

Both systems also reduce strain during installation, as they eliminate the need for heavy lifting or complex adjustments once the tray is positioned.

Aesthetic and Functional Harmony

Today's bathroom spaces blend functionality with visual harmony. Riser kits appeal to those who prefer enclosed designs that hide the functional components beneath a clean platform. In contrast, adjustable leg frames provide a discreet yet accessible structure that supports modern design flexibility.

For architects and designers, the choice between these systems often depends on project goals. In luxury or custom builds, adjustable frames allow creative freedom and precise alignment with other fixtures. In standardized or prefabricated bathrooms, riser kits maintain design uniformity and ease of replication.

This balance between aesthetic continuity and functional performance demonstrates how installation systems have become integral to the design conversation — not just a technical afterthought.

Industry Trends and the Road Ahead

Market observations suggest that adjustable shower tray leg frames are gradually gaining popularity, particularly in residential renovations. Their adaptability suits diverse flooring conditions and evolving plumbing layouts. At the same time, riser kits remain strong in commercial projects, where uniform installations and minimal maintenance are prioritized.

The growing interest in sustainable construction has also influenced these choices. Adjustable frames, which can be reused or re-leveled without replacing the entire base, align with the principles of waste reduction and longevity. As more builders adopt eco-conscious practices, such versatility adds long-term value to bathroom design.

In addition, the shift toward do-it-yourself home improvement has fueled consumer demand for straightforward, modular solutions. Both riser kits and adjustable frames cater to this trend, offering reliable systems that don't require advanced technical skills to install.

Choosing Between Riser Kits and Adjustable Leg Frames

Ultimately, the decision between the two systems comes down to priorities.

If the project requires a quick, enclosed setup with minimal adjustments, a riser kit may be the right fit. It provides stability and a seamless look suitable for fixed-height installations.

If flexibility, access, and adaptability are key concerns, an adjustable shower tray leg frame becomes the preferred option. It allows installers to accommodate uneven floors, adjust drainage alignment, and modify height when needed — all without compromising structure or safety.

Regardless of the choice, correct installation practices remain essential. Proper sealing, weight distribution, and leveling ensure that both systems perform effectively and last for years.

A Shared Role in the Future of Bathroom Design

The relationship between riser kits and adjustable leg frames is not about competition but coexistence. Each system fills a different need within modern construction. Together, they represent a broader shift toward more intelligent, adaptable, and maintenance-friendly bathroom solutions.

As renovation techniques continue to evolve, these innovations will play a vital role in defining how bathrooms are constructed — emphasizing precision, accessibility, and sustainability. Whether in new builds or remodeling projects, the right support system beneath a shower tray contributes to a safer, more efficient, and more comfortable living environment.

The growing popularity of riser kits and adjustable shower tray leg frames illustrates a significant movement in bathroom construction — one that values flexibility, ease of maintenance, and long-term reliability. Homeowners and professionals alike now recognize that what lies beneath the surface of a shower installation is just as important as what meets the eye.

As the industry moves forward, the integration of these systems will continue to refine how bathrooms are built. The adjustable frame's adaptability complements the riser kit's simplicity, offering solutions for a wide range of architectural needs. This evolution highlights a simple truth: thoughtful engineering at the foundation of every shower installation leads to improved function, extended lifespan, and lasting comfort in modern living spaces.

русский

русский  Español

Español